Infiniti FX35, FX50 (S51). Manual - part 584

DIFFERENTIAL ASSEMBLY

DLN-171

< UNIT DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: F160A]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

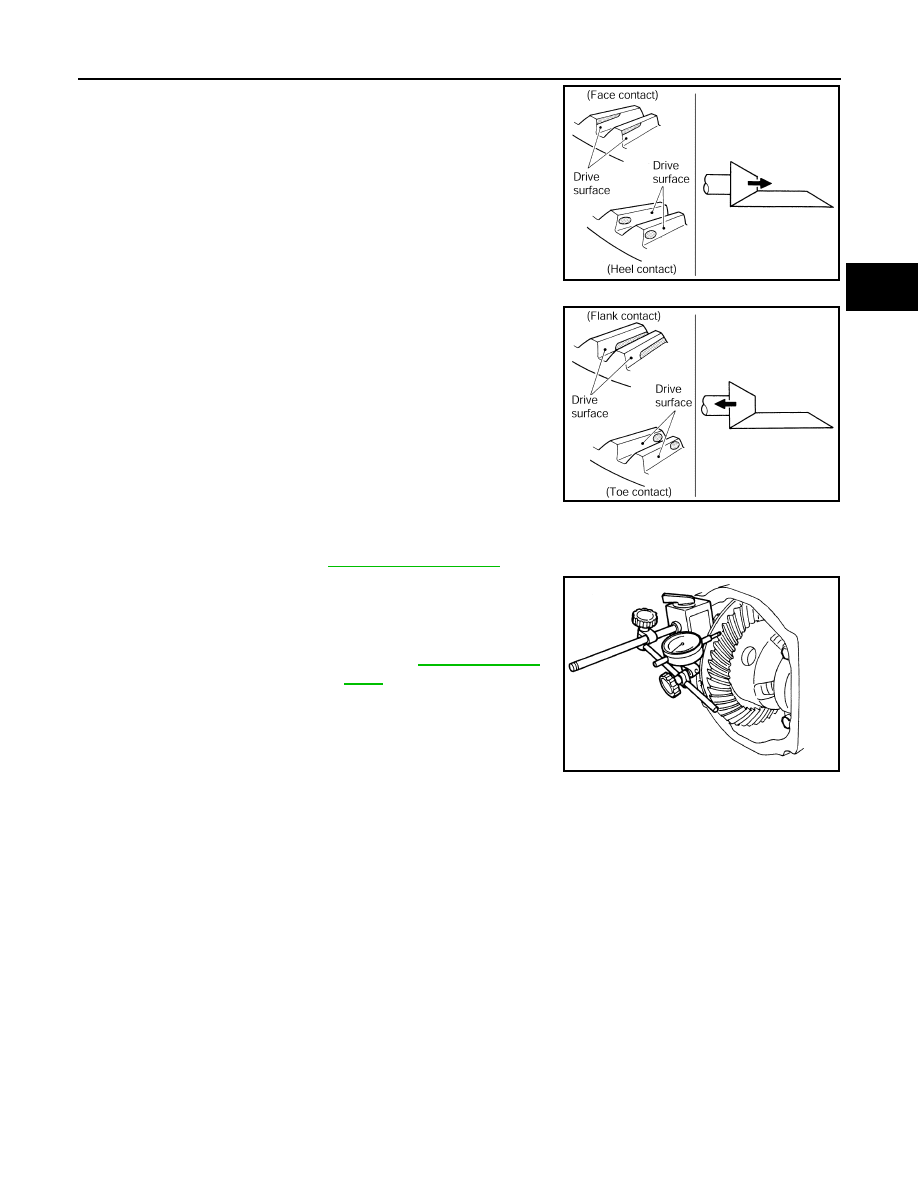

• If the tooth contact is near the face (face contact), or near the

heel (heel contact), thicken pinion height adjusting washers to

move drive pinion closer to drive gear.

• If the tooth contact is near the flank (flank contact), or near the

toe (toe contact), thin pinion height adjusting washers to move

drive pinion farther from drive gear.

BACKLASH

Before inspection and adjustment, drain gear oil.

1.

Remove carrier cover. Refer to

2.

Fit a dial indicator to the drive gear face to measure the back-

lash.

• If the backlash is outside of the specified value, change the

thickness of side bearing adjusting washer.

Inspection After Disassembly

INFOID:0000000005249205

DRIVE GEAR AND DRIVE PINION

• Clean up the disassembled parts.

• If the gear teeth never mesh or line-up correctly, determine the cause and adjust or replace as necessary.

• If the gears are worn, cracked, damaged, pitted or chipped (by friction) noticeably, replace with new drive

gear and drive pinion as a set.

BEARING

• Clean up the disassembled parts.

• If any chipped (by friction), pitted, worn, rusted or scratched marks, or unusual noise from the bearing is

observed, replace as a bearing assembly (as a new set).

SIDE GEAR AND PINION MATE GEAR

• Clean up the disassembled parts.

• If any cracks or damage on the surface of the tooth is found, replace.

PDIA0440E

PDIA0441E

Standard

Backlash

: Refer to

.

When the backlash is large:

Decrease side bearing adjusting washer thickness.

When the backlash is small:

Increase side bearing adjusting washer thickness.

SDIA0009J