Infiniti FX35, FX50 (S51). Manual - part 585

DRIVE PINION

DLN-175

< UNIT DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: F160A]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

Disassembly

INFOID:0000000005249207

1.

Remove differential case assembly. Refer to

2.

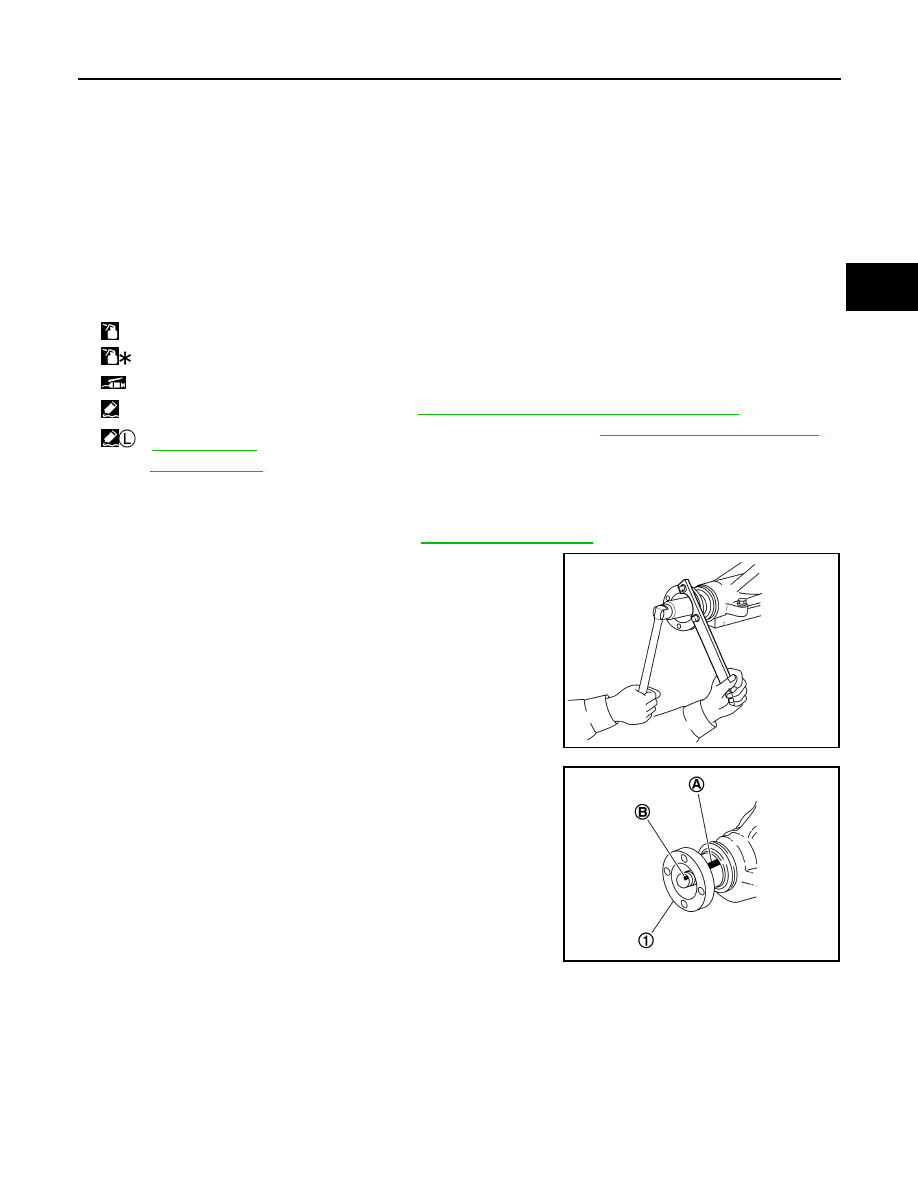

Remove drive pinion lock nut with a flange wrench.

3.

Put matching mark (B) on the end of drive pinion. The matching

mark should be in line with the matching mark (A) on companion

flange (1).

CAUTION:

For matching mark, use paint. Never damage companion

flange and drive pinion.

NOTE:

The matching mark (A) on the final drive companion flange (1)

indicates the maximum vertical runout position.

When replacing companion flange, matching mark is not neces-

sary.

10. Drive pinion

11.

Drive gear

12. Side oil seal (right side)

13. Side retainer

14. O-ring

15. Side bearing adjusting shim

16. Side bearing

17. Differential case

18. Breather connector

19. Dowel pin

20. Filler plug

21. Drain plug

22. Gasket

23. Carrier cover

24. Gear oil defense

25. Side gear thrust washer

26. Side gear

27. Circular clip

28. Pinion mate thrust washer

29. Pinion mate gear

30. Pinion mate shaft

31. Lock pin

32. Side bearing adjusting washer

33. Side oil seal (left side)

34. Side shaft bearing

35. Extension tube retainer

36. Side shaft oil seal

37. Dust seal

38. Side shaft

A:

Oil seal lip

B:

Screw hole

: Apply gear oil.

: Apply anti-corrosion oil.

: Apply multi-purpose grease.

: Apply Genuine Silicone RTV or equivalent. Refer to

GI-16, "Recommended Chemical Products and Sealants"

.

:

Apply Genuine Medium Strength Thread Locking Sealant or equivalent. Refer to

GI-16, "Recommended Chemical Prod-

.

Refer to

for symbols not described above.

PDIA0798J

PDIA0799J