Hyundai Elantra Neos / Hyundai i30. Manual - part 17

BP-4

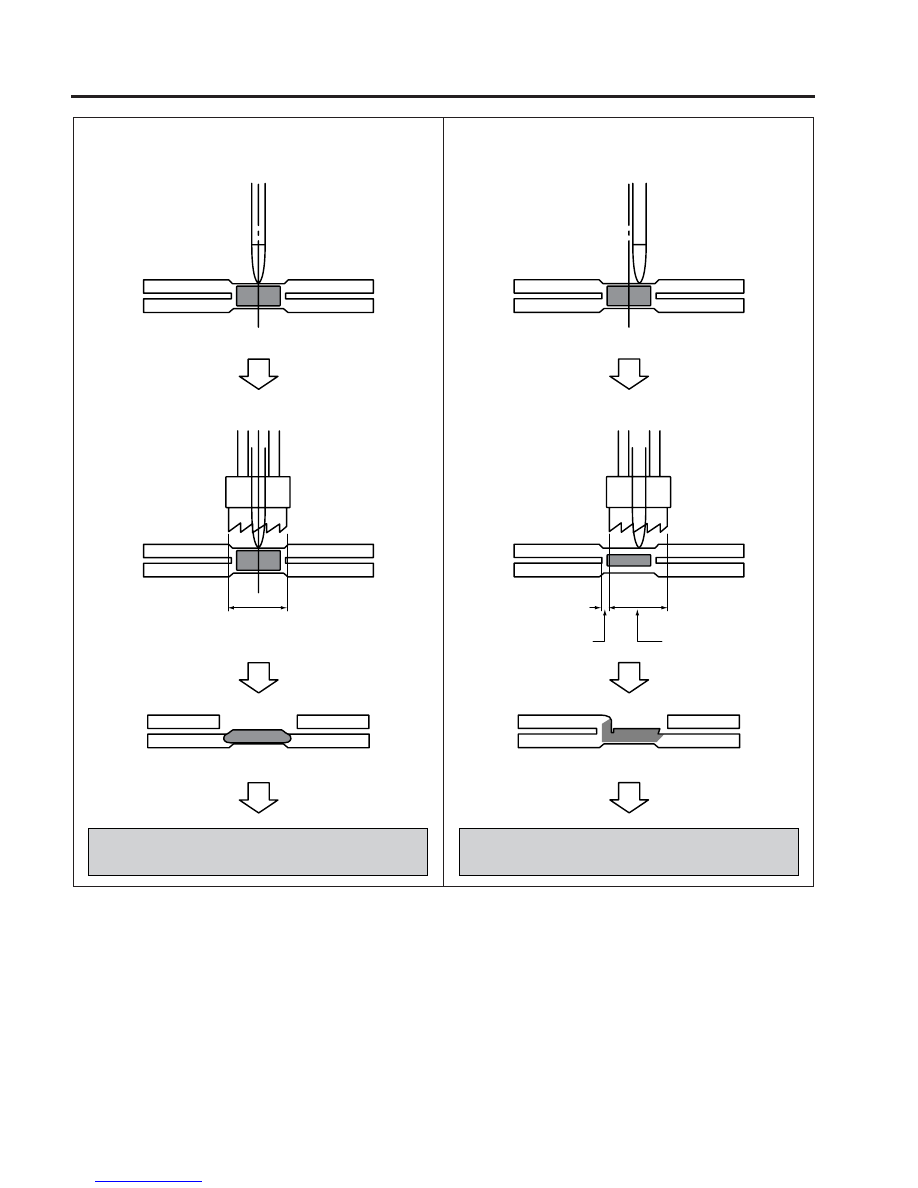

BODY PANEL REPAIR PROCEDURE

BVQBP6003

Center punch the middle(nugget) of the spot weld.

Otherwise,

Spot welded area can be removed from the body frame.

Spot welded area cannot be removed from the body

frame.

This part will not be cut.

This part will be cut.