Hummer H1 (1992-1998). Manual - part 32

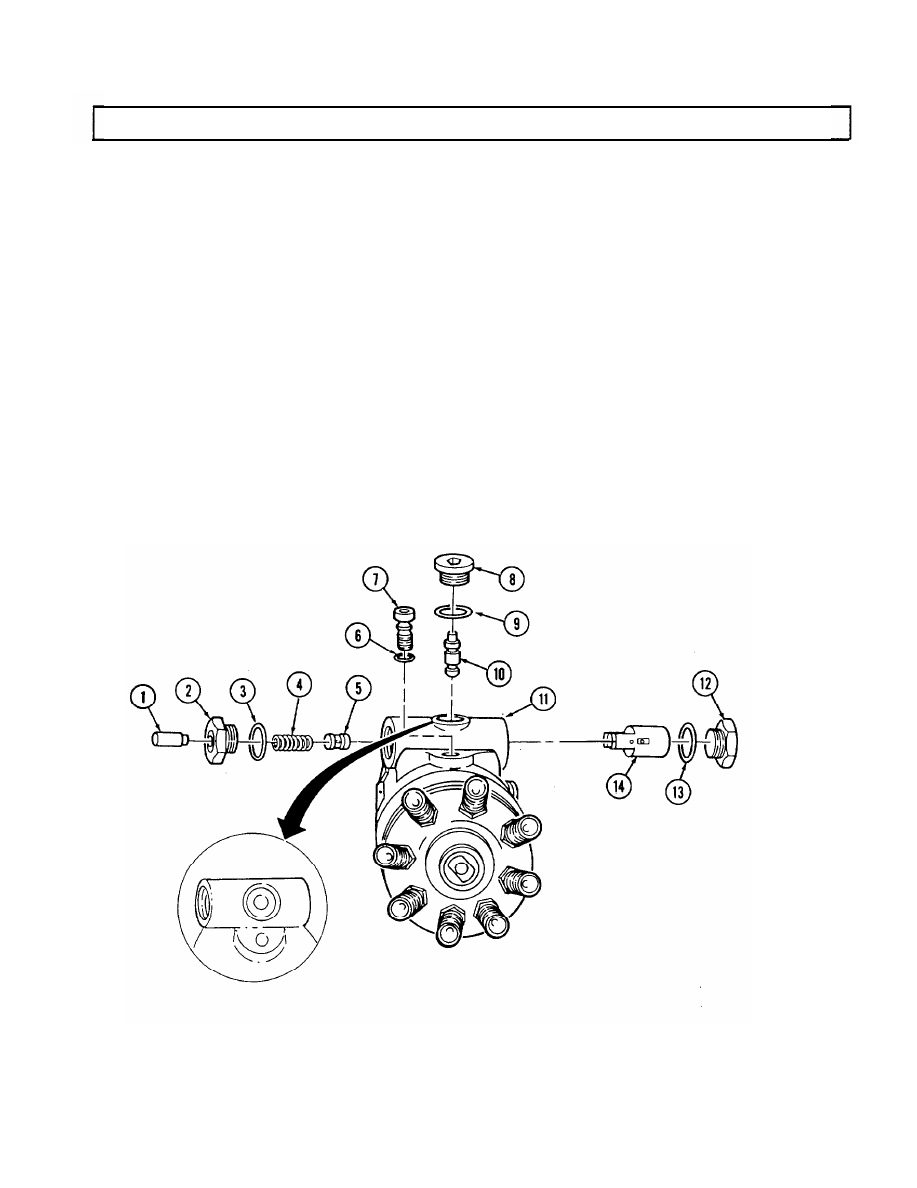

2-32. FUEL INJECTION PUMP REPAIR (Cont’d)

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

Rotate housing (11) and holding fixture in vise so advance plug (8) faces up.

Install O-ring (6) on head locating screw (7).

Lightly coat head locating screw (7) with seal lubricant and install in housing (11). Tighten screw (7)

to 180-220 lb-in. (20-25 N•m) using 5/16-in. hex head driver.

Install servo advance piston (14) in housing (11) with notch and two small holes facing head locating

screw (7).

Install O-ring (13) and power side advance piston hole plug (12) in housing (11). Tighten plug (12) to

215-265 lb-in. (24-30 N•m).

NOTE

Rotate cam ring to align hole for cam advance pin in housing.

Install cam advance pin (10).

Install O-ring (9) and advance plug (8) in housing (11). Tighten advance plug (8) with 1/4-in. hex

head driver to 75-100 lb-in. (9-11 N•m).

Install servo advance valve (5) on spring (4) and install servo advance valve (5) in servo advance

piston (14).

Install servo advance plunger (1) and O-ring (3) on spring side plug (2).

Install spring side plug assembly (2) in housing (11) so servo advance plunger (1) fits in spring (4).

Tighten sprinig side plug assembly (2) to 215-265 lb-in. (24-30 N•m).

2-116