Honda Element. Manual - part 591

1. Connect the Honda Diagnostic System (HDS) to the data link connector (DLC) (see step 2 on HOW TO

USE THE HDS (HONDA DIAGNOSTIC SYSTEM) ).

2. Turn the ignition switch ON (II).

3. Make sure the HDS communicates with the vehicle and the engine control module (ECM)/powertrain

control module (PCM). If it doesn't communicate, troubleshoot the DLC circuit (see DLC CIRCUIT

TROUBLESHOOTING ).

4. Check for DTCs (see GENERAL TROUBLESHOOTING INFORMATION ). If a DTC is present,

diagnose and repair the cause before continuing with this test.

5. Start the engine. Hold the engine speed at 3,000 rpm with no load (in the N or P position) until the

radiator fan comes on, then let it idle.

6. Check the idle speed (see IDLE SPEED INSPECTION ).

7. Jump the SCS line with the HDS.

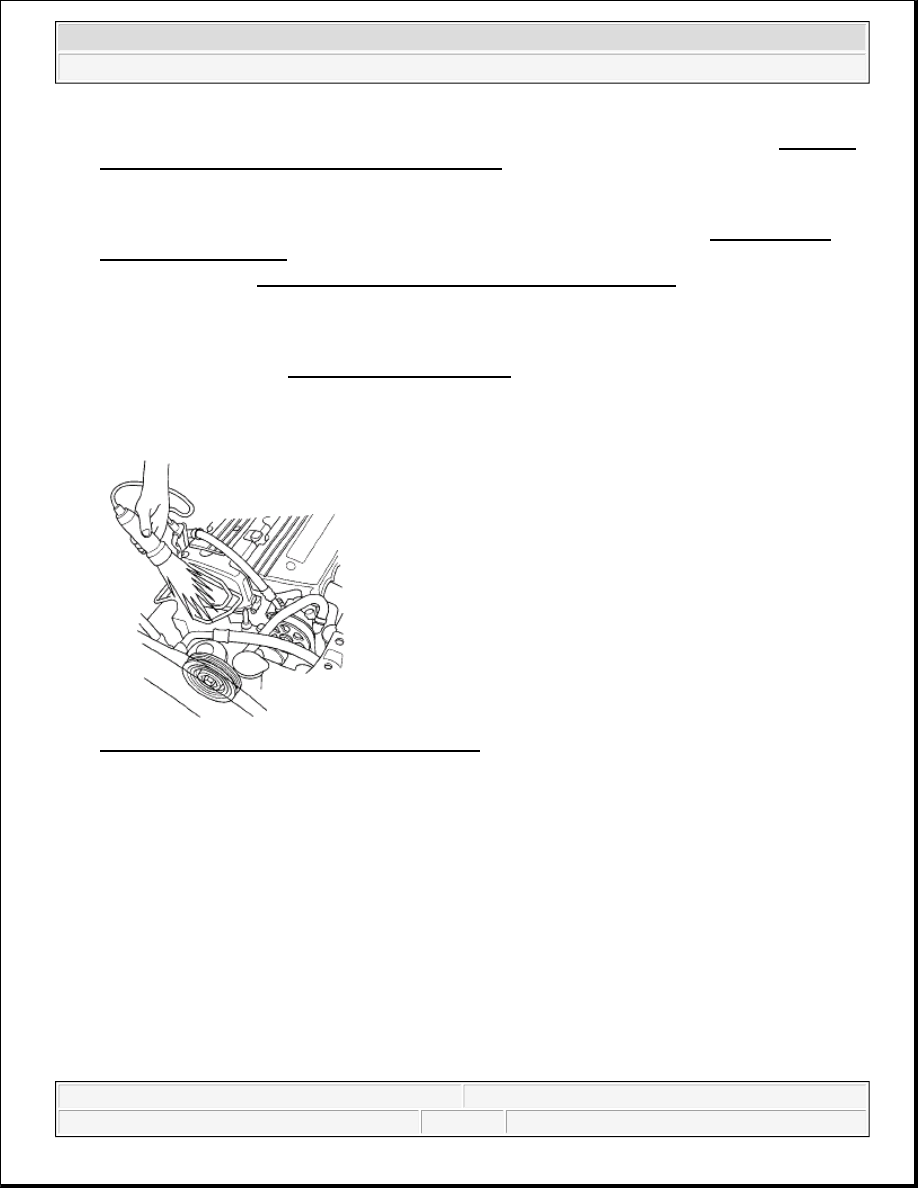

8. Free the service loop from the wire harness, then connect the timing light to the service loop.

Fig. 3: Connecting Timing Light To Service Loop

Courtesy of AMERICAN HONDA MOTOR CO., INC.

9. Aim the light toward the pointer (A) on the cam chain case. Check the ignition timing under a no load

condition (headlights, blower fan, rear window defogger, and air conditioner are turned off).

Ignition Tinning

M/T: 8° ± 2° BTDC (RED mark (B)) at idle in the Neutral

A/T: 8° ± 2° BTDC (RED mark (B)) at idle in the N or P position

2007 Honda Element EX

2007-08 ENGINE Ignition System - Element