Great Wall Hover. Manual - part 35

v. Install the thrust disc on the cylinder internal wheel axle. Refer to Figure 8.24and 8.19.

w. Connect the C2 /clutch C4 wheel axle assembly in clutch C4 disc, install the clutch C2 disc. Install the C3 wheel axle and

reinforce it by ring spring; ensure the ring spring is installed in the groove fixedly. Please refer to Figure 8.24.

10. Clutch C3 and reverse central gear system

The assembly procedure of clutch C3 and reverse central gear assembly (refer to Figure 8.28) is shown as follows:

Check the cleanness of hole on cylinder.

Caution:

It should take out the clutch clearance assembly before immerse the assembly into the automatic transmission fluid

(ATF).

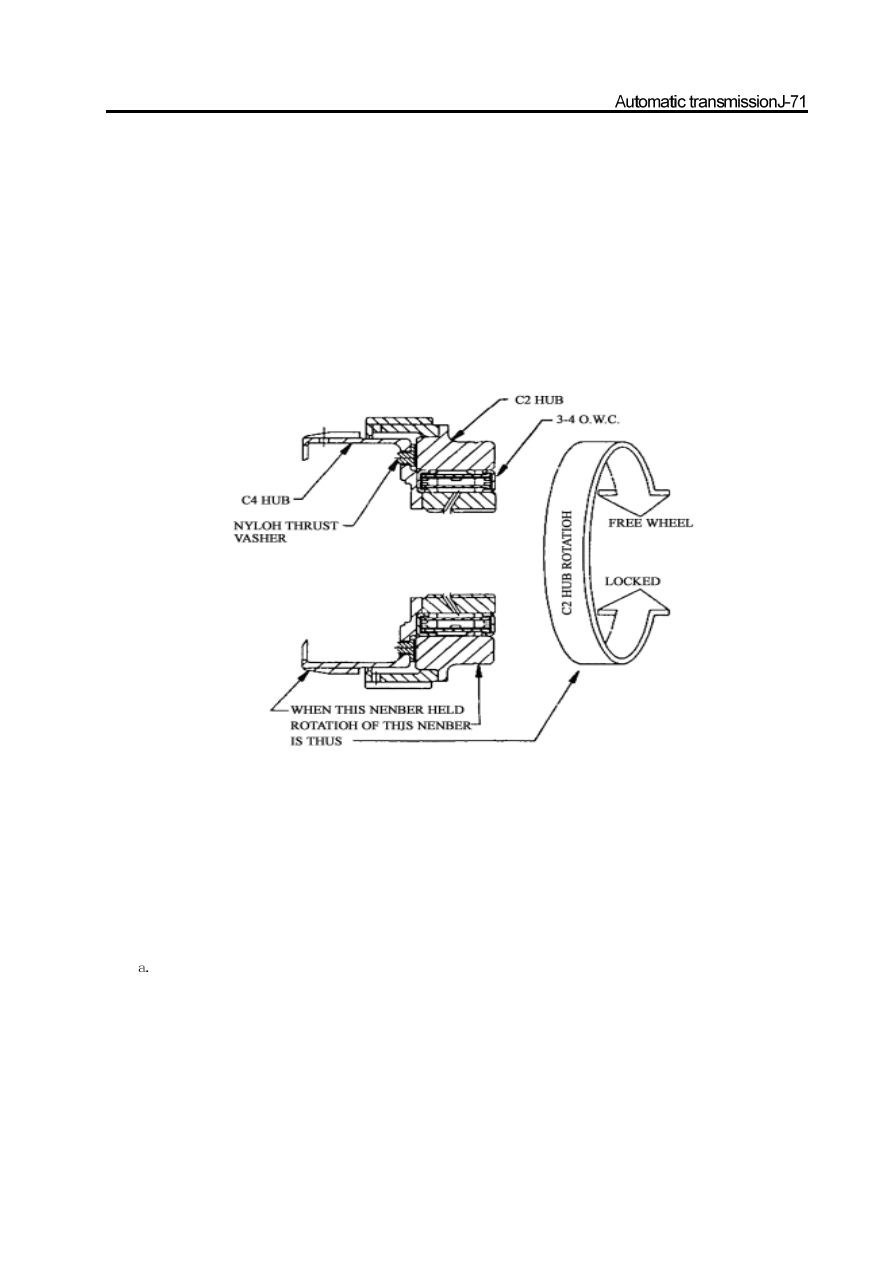

s. Use the gear selection plate to reach the correct specification. It should remove the clutch assembly and immerse the friction

disk in the automatic transmission fluid for 5 minutes at least before the installation if install the new friction disks. Lubricate

and install the 3-4 one-way clutch and install the sleeve on the C2 wheel axle. Adjust the handle rear and install the nylon thrust

washer on the C4 wheel axle. Refer to Figure 8.27.

t. Adjust and install the clutch C4 wheel axle on the clutch C2 and one-way clutch assembly. Check the rotary direction of clutch

C2 wheel axle, when keep the C4 wheel axle in static, C2 wheel axle should rotate in clockwise and is locked in anticlockwise.

Refer to Figure 8.27.

u. Use the Vaseline to lubricate the N0.5 thrust bearing and install it on the C4 gear wheel axle ,separate the clutch C2 disc form

the clutch cylinder.

Figure 8.27 C2 hub rotation