Great Wall Hover. Manual - part 32

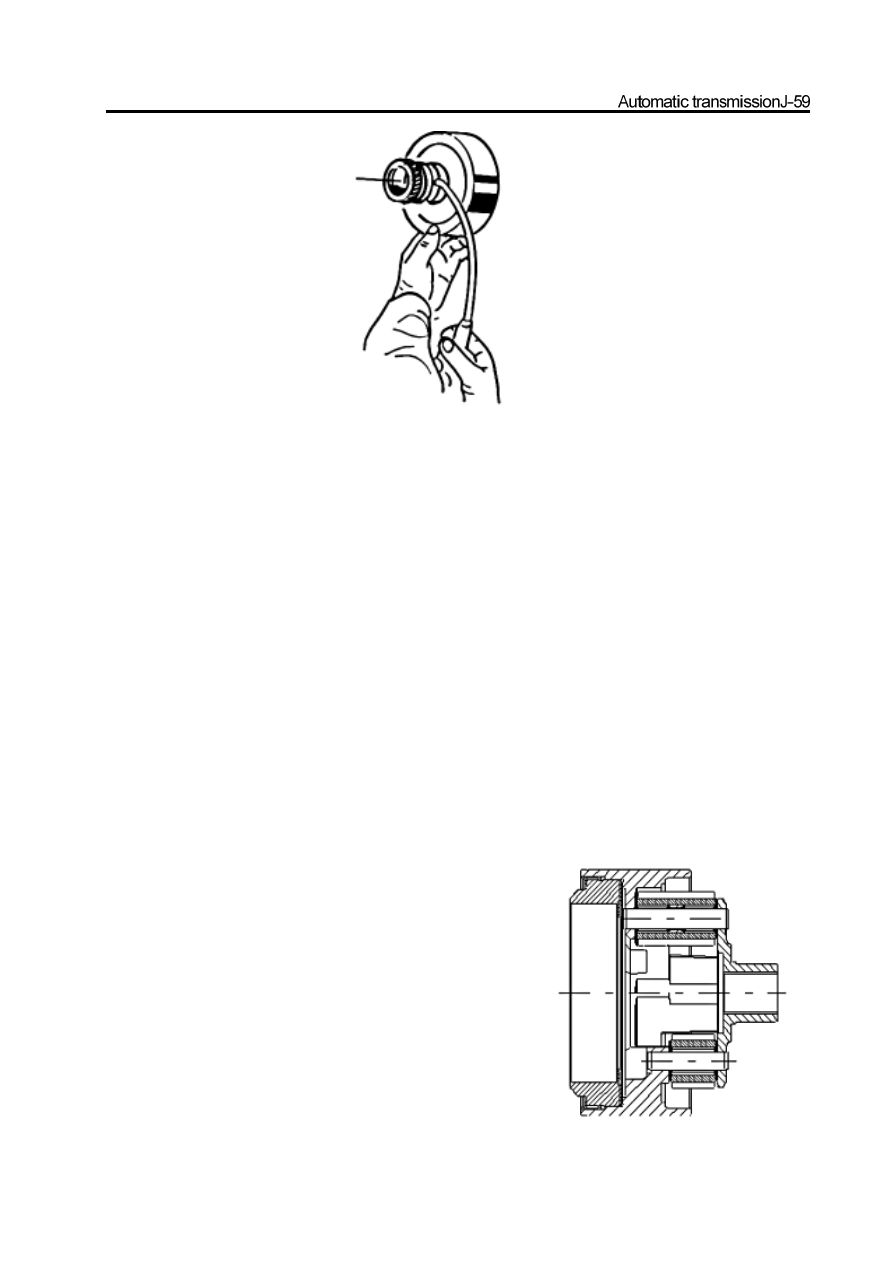

Figure 8.8 Removal of clutch C3 piston

c. Install the clutch assembly on the special tools, press down the piston out-back spring; take out the retainer and release spring.

Caution:

Ensure the spring keeping device does not be clamped in the spring groove and all spring pressure is released.

d. Take out the tools, retainer, retainer and spring.

e. Take out the gasket from the clutch C3 cylinder.

f. Take out the clutch disk fixed spring ring and take out the clutch disk.

g. Send the compressed air into the hole between the iron sealing ring and support shaft neck of cylinder; remove the clutch piston

from the clutch cylinder. Refer to Figure 8.8.

h. Take out the cylinder forms the reverse sun gear and C3 washer.

5. Planet carrier and central support

The disassembly procedure of planet carrier and central support, the procedure is shown as follows:

a. Separate the planet carrier and central support from the output shaft; remove the thrust bearing and planet carrier form the

output shaft.

b. Rotate the planet carrier in anticlockwise and separate the central bracket.

c. Raise the one-way clutch form the planet carrier

d. Remove the spring ring on the planet carrier; maintain the periphery of one-way clutch on the planet carrier and take it out.

Refer to Figure 8.9.

e. Remove the one-way clutch fixed mount form the planet carrier.

Figure 8.9 Planet carrier and external race way