Great Wall Hover. Manual - part 30

Automatic transmission-51

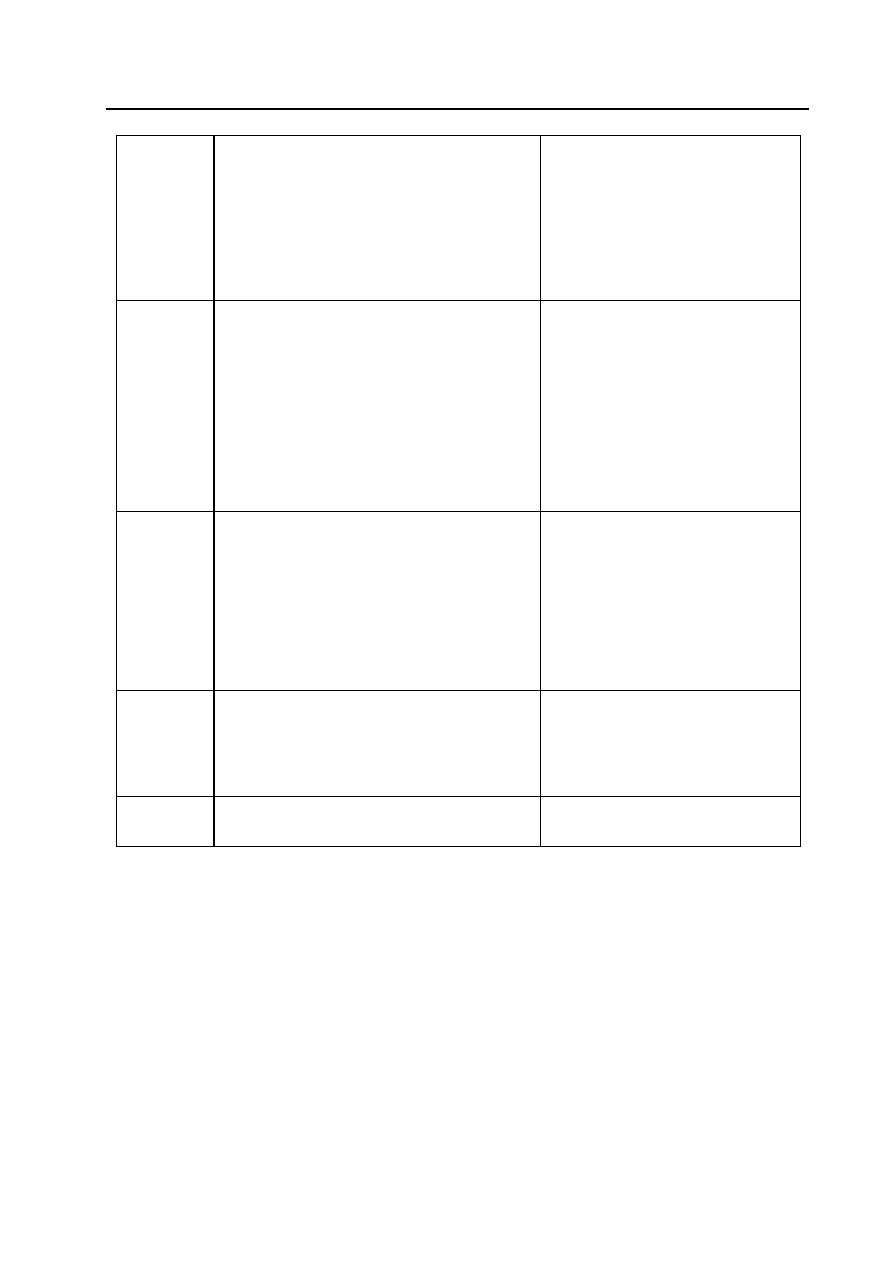

Table 6.2.3

Shifting quality failure

Bad 1→2 Gear

shifting quality

The throttle position sensor has failure.

The brake belt is adjusted incorrectly.

The front servo piston O-ring is damaged.

The variable pressure solenoid valve (S5) is damaged or

has failure.

S1, S4 has the failure.

The brake belt combination regulating valve (BAR) has

the failure.

The front servo release spring is installed incorrectly.

Detect the resistance, replace the sensor if

necessary.

Detect and replace the rake belt if necessary.

Detect and replace the O-ring if necessary.

Detect, repair or replace the S5 if necessary.

Detect, repair or replace the S1, S4 if

necessary.

Detect, repair or replace the BAR if

necessary.

Detect and repair it if necessary.

Bad 2→3 Gear

shifting quality

B1brake belt release valve is blocked.

S3, S2 has the failure.

The clutch combination regulating valve has failure.

The clutch combination oil feed ball spool is lost or

damaged.

The input shaft oil seal is damaged.

C1 piston O-ring is damaged.

C1 piston oil feed ball spool is damaged.

Detect the blow-off valve. Replace or

maintain it if necessary.

Detect the S3, S2.Replace or maintain it if

necessary.

Detect the regulating valve. Replace or

maintain it if necessary.

Detect the ball spool .Reinstall or replace it if

necessary.

Detect the sealing ring. Reinstall or replace it

if necessary.

Detect the O-ring .Reinstall or replace it if

necessary.

Detect the ball spool .Reinstall or replace it if

necessary.

Bad 3→4 Gear

shifting quality

S1, S4 has failure.

B1brake belt release valve is blocked.

The brake belt is adjusted incorrectly.

The front servo piston O-ring is damaged.

The variable pressure solenoid valve (S5) is damaged or

has failure.

The brake belt combination regulating valve has failure.

Detect the S1, S4.Reinstall or replace it if

necessary.

Detect the blow-off valve. Replace or repair

it if necessary.

Detect the brake belt. Adjust it if necessary.

Detect the O-ring .Replace or maintain it if

necessary.

Detect the S5.Replace or maintain it if

necessary.

Detect the regulating valve. Replace or

maintain it if necessary.

The engine has

the

extinguishing

condition

when select

the automatic

gear or R-gear.

The torque converter clutch control valve is blocked or

solenoid valve 7 has failure.

Detect and clean the torque converter clutch

valve (CCCV)

Has unstable

vibration

condition.

S7 has the failure.

Process the necessary detection, maintenance

and replacement according to the

requirement.