Great Wall Hover. Manual - part 17

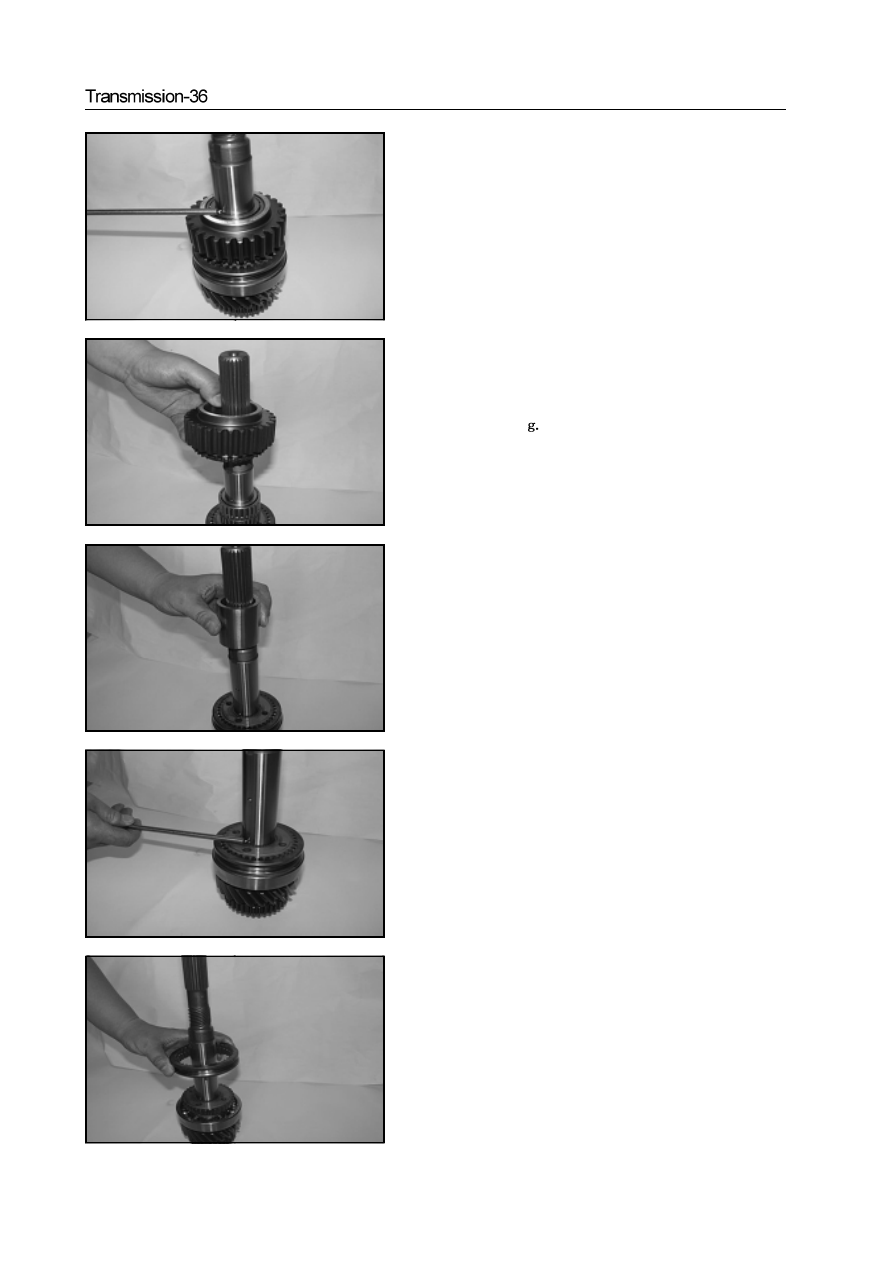

e. Use the magnetic rod to remove the steel ball.

f. Remove the drive sprocket and needle bearing

Caution: When install the drive sprocket, it should use the plug

gage to measure the drive sprocket axial clearance and ensure

within 0.19-0.338mm

g Remove the drive geared sleeve

h. Use the magnetic rod to remove the steel ball.

i. Dismantle the drive gear sleeve.