содержание .. 92 93 94 95 96 97 98 99 100 ..

Geely Diagnosis Flow. Manual part - 99

393

How to inspect the refrigeration oil volume in air conditioning compressor

The vehicle air conditioning compressor is a high-speed operation device. Its normal condition depends on the

sufficiency of the refrigeration oil, however excess refrigeration oil will influence the refrigerating effect. Oil

volume inside the compressor must be checked when the compressor or part of the refrigeration system are

replaced. The inspection methods are as follows:

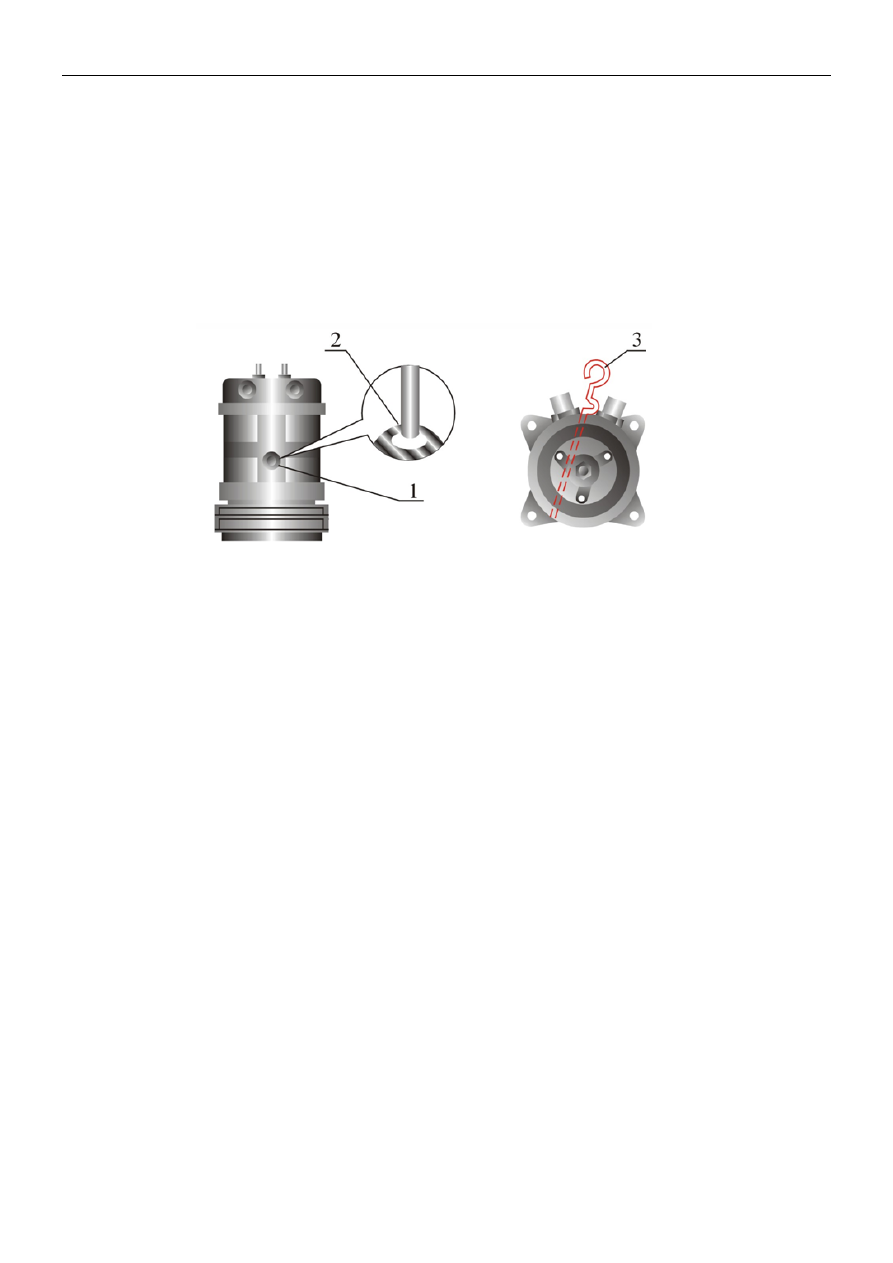

Fig.4-5 shows the inspection to the refrigeration oil volume. Discharge the oil charge plug 1, watch it via the oil

charge taphole and rotate the clutch foreplate; Wipe clean the oil dipstick with the cotton yarn and insert it into

the compressor until end of the oil dipstick touches inner casing of the compressor; take out the oil dipstick and

observe its immersion depth; oil level inside the compressor shall be between scale 4 and scale 6 if the oil

charging is appropriate. Add it if it is inadequate and drain if it is excessive, then tighten the filling port plug.

Fig. 4-5 inspection to the refrigeration lubrication oil volume of the sedan air conditioning compressor

1- oil filling plug 2- Filling port 3- oil dipstick

Provided there is no oil filling plug hole in the compressor, the oil shall be poured into a measuring cup to

make the comparison with the oil charge volume specified in the instruction to judge if the compressor is

required to add the oil. Generally oil content in the compressor shall not be less than 1/3 oil charging volume

specified in the instruction, or else the oil shall be added. Compressor provided with the oil charging plug hole

can also adopt this method, but the compressor assembly must be removed from the air-conditioning system.