Ford Fiesta (1989-1995). Instruction - part 35

7

Fuel pump/fuel pressure -

checking

3

Note: Refer to the warning note in Section 1

before proceeding.

Fuel pump operation check

1 Switch on the ignition, and listen for the fuel

pump (the sound of an electric motor running,

audible from beneath the rear seats).

Assuming there is sufficient fuel in the tank,

the pump should start and run for

approximately one or two seconds, then stop,

each time the ignition is switched on. Note: If

the pump runs continuously all the time the

ignition is switched on, the electronic control

system is running in the backup (or “limp-

home”) mode referred to by Ford as “Limited

Operation Strategy” (LOS). This almost

certainly indicates a fault in the EEC IV module

itself, and the vehicle should therefore be

taken to a Ford dealer for a full test of the

complete system, using the correct diagnostic

equipment; do not waste time or risk

damaging the components by trying to test

the system without such facilities.

2 Listen for fuel return noises from the fuel

pressure regulator. It should be possible to

feel the fuel pulsing in the regulator and in the

feed hose from the fuel filter.

3 If the pump does not run at all, check the

fuse, relay and wiring (see Chapter 12). Check

also that the fuel cut-off switch has not been

activated and if so, reset it.

Fuel pressure check

4 A fuel pressure gauge will be required for

this check and should be connected in the

fuel line between the fuel filter and the fuel rail,

in accordance with the gauge maker’s

instructions. On Zetec engines, a pressure

gauge equipped with an adapter to suit the

Schrader-type valve on the fuel rail pressure

test/release fitting (identifiable by its blue

plastic cap, and located on the union of the

fuel feed line and the fuel rail) will be required.

If the Ford special tool 29-033 is available, the

tool can be attached to the valve, and a

conventional-type pressure gauge attached to

the tool.

5 If using the service tool, ensure that its tap

is turned fully anti-clockwise, then attach it to

the valve. Connect the pressure gauge to the

service tool. If using a fuel pressure gauge

with its own adapter, connect it in accordance

with its maker’s instructions.

6 Start the engine and allow it to idle. Note

the gauge reading as soon as the pressure

stabilises, and compare it with the regulated

fuel pressure figures listed in the

Specifications.

a) If the pressure is high, check for a

restricted fuel return line. If the line is

clear, renew the fuel pressure regulator.

b) If the pressure is low, pinch the fuel return

line. If the pressure now goes up, renew

the fuel pressure regulator. If the pressure

does not increase, check the fuel feed

line, the fuel pump and the fuel filter.

7 Detach the vacuum hose from the fuel

pressure regulator; the pressure shown on the

gauge should increase. Note the increase in

pressure, and compare it with that listed in the

Specifications. If the pressure increase is not

as specified, check the vacuum hose and

pressure regulator.

8 Reconnect the regulator vacuum hose, and

switch off the engine. Verify that the hold

pressure stays at the specified level for five

minutes after the engine is turned off.

9 Carefully disconnect the fuel pressure

gauge, depressurising the system first as

described in Section 2. Be sure to cover the

fitting with a rag before slackening it. Mop up

any spilt petrol.

10 Run the engine, and check that there are

no fuel leaks.

8

Fuel tank - removal,

inspection and refitting

3

Proceed as described in Part A, Section 8,

but before disconnecting the battery, relieve

the residual pressure in the fuel system (see

Section 2), and equalise tank pressure by

removing the fuel filler cap.

9

Fuel pump/fuel gauge

sender unit - removal and

refitting

3

Refer to Part B, Section 9.

10 Fuel tank ventilation tube -

removal and refitting

3

Refer to Part A, Section 10, but note that

the ventilation tube connects to the combined

roll-over/anti-trickle-fill valve assembly but,

instead of venting to atmosphere, a further

tube runs the length of the vehicle to the

evaporative emission control system carbon

canister in the front right-hand corner of the

engine compartment.

Further information on the evaporative

emission control system is contained in Part E

of this Chapter.

11 Fuel tank filler pipe -

removal and refitting

3

Refer to Part A, Section 11.

12 Fuel cut-off switch -

removal and refitting

1

Refer to Part B, Section 12.

13 Fuel injection system -

checking

3

Refer to Part B, Section 13

14 Fuel injection system

components - removal and

refitting

3

Note: Refer to the warning note in Section 1

before proceeding.

Throttle housing

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the air inlet components as

described in Section 4.

3 Disconnect the accelerator cable from the

throttle linkage (see Section 5).

4 Disconnect the throttle position sensor

multi-plug.

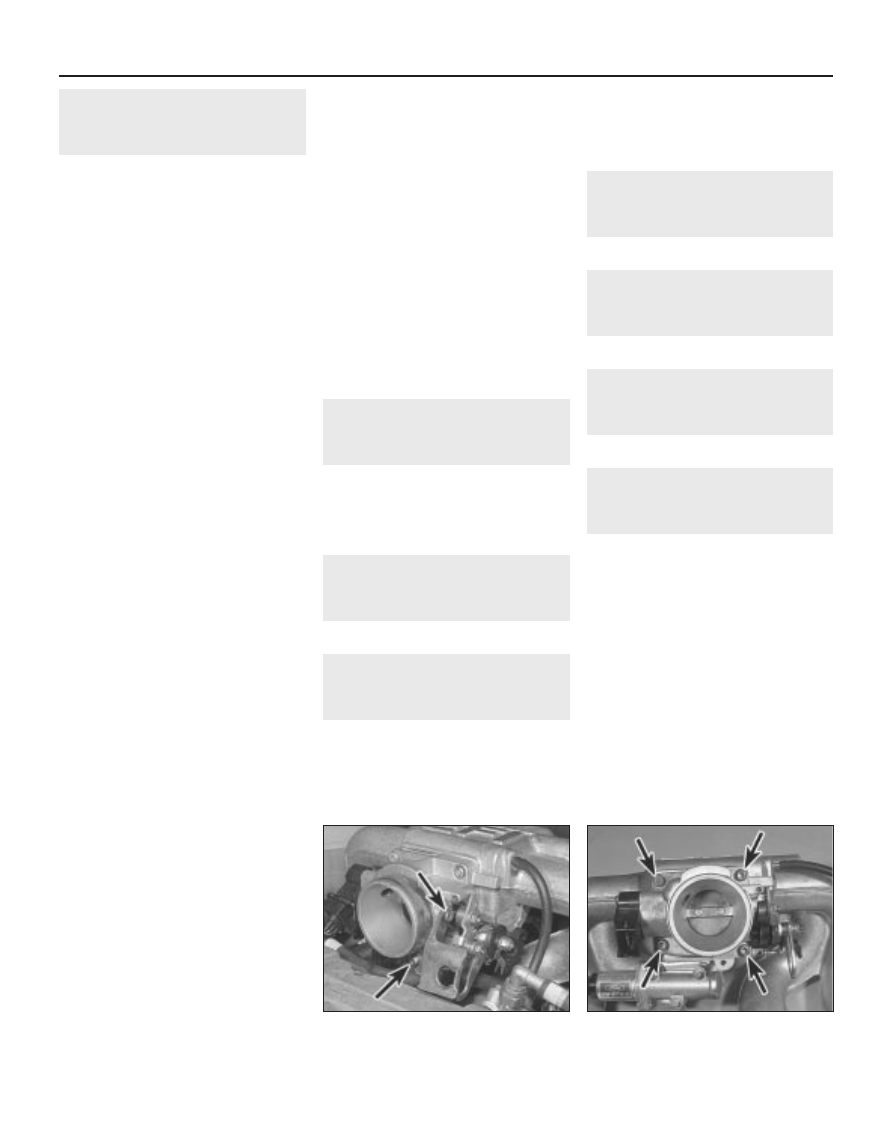

5 Unscrew the retaining bolts, and detach the

accelerator cable support bracket at the

throttle housing (see illustration).

6 Unscrew the throttle housing-to-manifold

retaining bolts (see illustration), and unbolt

the throttle housing support bracket bolts

(where fitted). Remove the throttle housing

4D•4 Fuel system - sequential electronic fuel injection engines

14.6 Throttle housing retaining bolts

(arrowed)

14.5 Unscrew the retaining bolts (arrowed),

and detach the accelerator cable support

bracket

1595Ford Fiesta Remake