Ford Fiesta (1989-1995). Instruction - part 33

8

Fuel tank - removal,

inspection and refitting

3

Proceed as described in Part A, Section 8,

but before disconnecting the battery, relieve

the residual pressure in the fuel system (see

Section 2), and equalise tank pressure by

removing the fuel filler cap.

9

Fuel pump/fuel gauge

sender unit - removal and

refitting

3

Refer to Part B, Section 9.

10 Fuel tank ventilation tube -

removal and refitting

3

Refer to Part A, Section 10, but note that on

models with evaporative emission control, the

ventilation tube connects to the combined

roll-over/anti-trickle-fill valve assembly but,

instead of venting to atmosphere, a further

tube runs the length of the vehicle to a carbon

canister in the front right-hand corner of the

engine compartment.

Further information on the evaporative

emission control system is contained in Part E

of this Chapter.

11 Fuel tank filler pipe -

removal and refitting

3

Refer to Part A, Section 11.

12 Fuel cut-off switch -

removal and refitting

1

Refer to Part B, Section 12.

13 Fuel injection system -

checking

3

Refer to Part B, Section 13

14 Fuel injection system

components - removal and

refitting

3

Note: Refer to the warning note in Section 1

before proceeding.

Fuel rail and injectors

Note: For simplicity, and to ensure that the

necessary absolute cleanliness on reassembly,

the following procedure describes the removal

of the fuel rail assembly, complete with the

injectors and pressure regulator, so that

the injectors can be serviced individually on a

clean work surface. It is also possible to remove

and refit an individual injector, once the fuel

system has been depressurised and the battery

has been disconnected. If this approach is

followed, read through the complete

procedure, and work as described in the

relevant paragraphs, depending on the amount

of preliminary dismantling required. Be careful

not to allow any dirt to enter the system.

1 Relieve the residual pressure in the fuel

system (see Section 2), and equalise tank

pressure by removing the fuel filler cap.

Warning: This procedure will

merely relieve the increased

pressure necessary for the engine

to run - remember that fuel will

still be present in the system components,

and take precautions accordingly before

disconnecting any of them.

2 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

3 Disconnect the HT lead connectors from the

spark plugs, and release the leads from their

locating grooves in the air inlet duct. Position

them out of the way. On Turbo models, undo the

two screws and remove the HT lead bracket.

4 Remove the air inlet components as

described in Section 4.

5 Unscrew the retaining nuts and the bolt,

and detach the accelerator cable support

bracket at the throttle housing.

6 Disconnect the wiring connector from the

throttle position sensor.

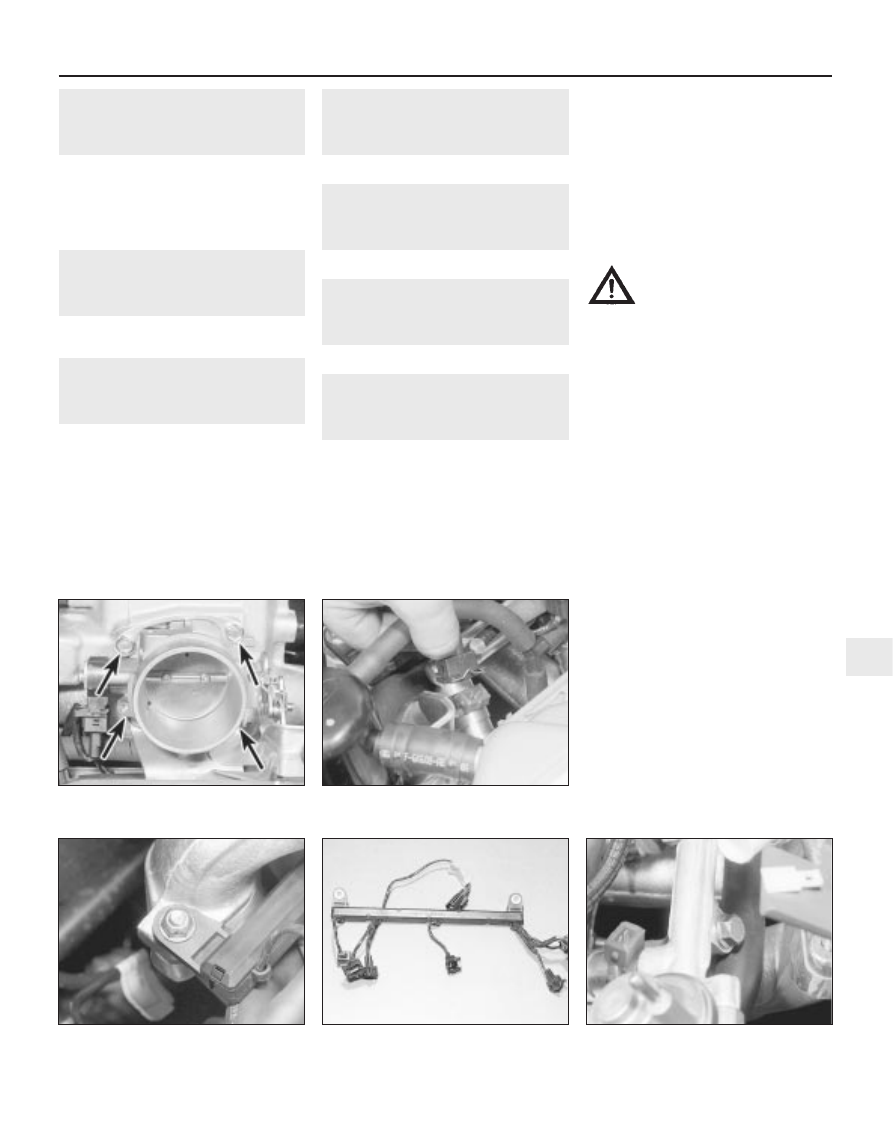

7 Unscrew the four retaining bolts, and

remove the throttle housing and its mating

face gasket (see illustration).

8 Disconnect the wiring multi-plug from the

engine coolant temperature sensor and the

inlet air temperature sensor.

9 Disconnect the wiring multi-plugs from the

fuel injectors, then undo the two retaining

bolts and detach the wiring harness from the

fuel rail (see illustrations).

10 Unscrew the fuel supply pipe at the fuel

rail. Plug the rail and pipe, to prevent further

fuel spillage and the possible ingress of dirt.

11 Disconnect the fuel return and vacuum

pipes from the pressure regulator, and catch

any fuel spillage in a clean cloth.

12 Unscrew the fuel rail securing bolts, and

carefully withdraw the rail (complete with

injectors) from the engine (see illustrations).

Fuel system - electronic fuel injection engines 4C•5

14.9b . . . unbolt the wiring harness . . .

14.9a Disconnect the wiring multi-plug

from each injector . . .

14.7 Throttle housing retaining bolt

locations (arrowed)

4C

1595Ford Fiesta Remake

14.12a Remove the fuel rail retaining

bolts . . .

14.9c . . . and remove the complete

harness