Daewoo Musso. Manual - part 311

5D2-46 TRANSFER CASE (TOD)

23. Remove the internal snap ring from the planetary carrier

and separate the front planet from the input shaft.

24. Remove the external snap ring from the input shaft. Place

the input shaft in a vise and remove the bearing. Remove

the thrust washer, thrust plate and the sun gear off the

input shaft.

25. Inspect the bushing and needle bearing in the end of the

input shaft for wear or damage.

Notice

Under normal use, the needle bearing and bushing should

not require replacement. If replacement is required, the

bushing and needle bearing must be replaced as a set.

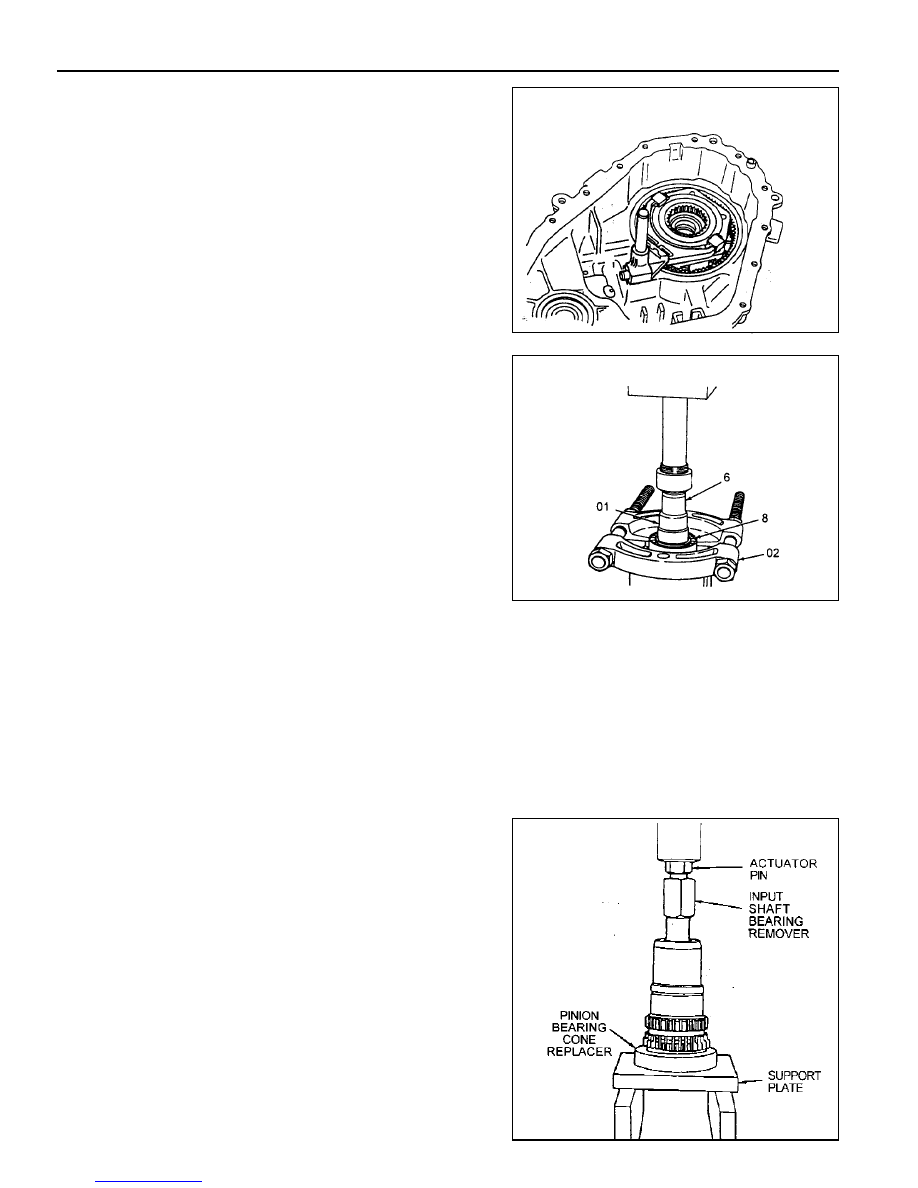

26. If replacement of the needle bearing and bushing is

required, press the bearing and bushing is required, press

the bearing and bushing out as follows:

a. Position the input shaft on Axle Bearing/Seal plate,and

using Pinion Bearing Cone Replacer as a spacer.

b. Insert Input Shaft Bearing Remover into the input shaft

so it is resting on top of the bearing cage.

c. Tighten the actuator pin until it stops, then press the

bearing and bushing out together.

6

Input Shaft

8

Bearig

01

Pinion Bearing Cone Remover

02

Compress the Dowel

27. If required, remove the front yoke to flange seal by prying

and pulling on the curved-up lip of the yoke to flange seal.

Do not damage the bearing, bearing cage or case.

28. If required, remove the internal snap ring retaining the

front output shaft ball bearing and remove the bearing.