Daewoo Musso. Manual - part 289

5C-12 CLUTCH

Inspection Procedure

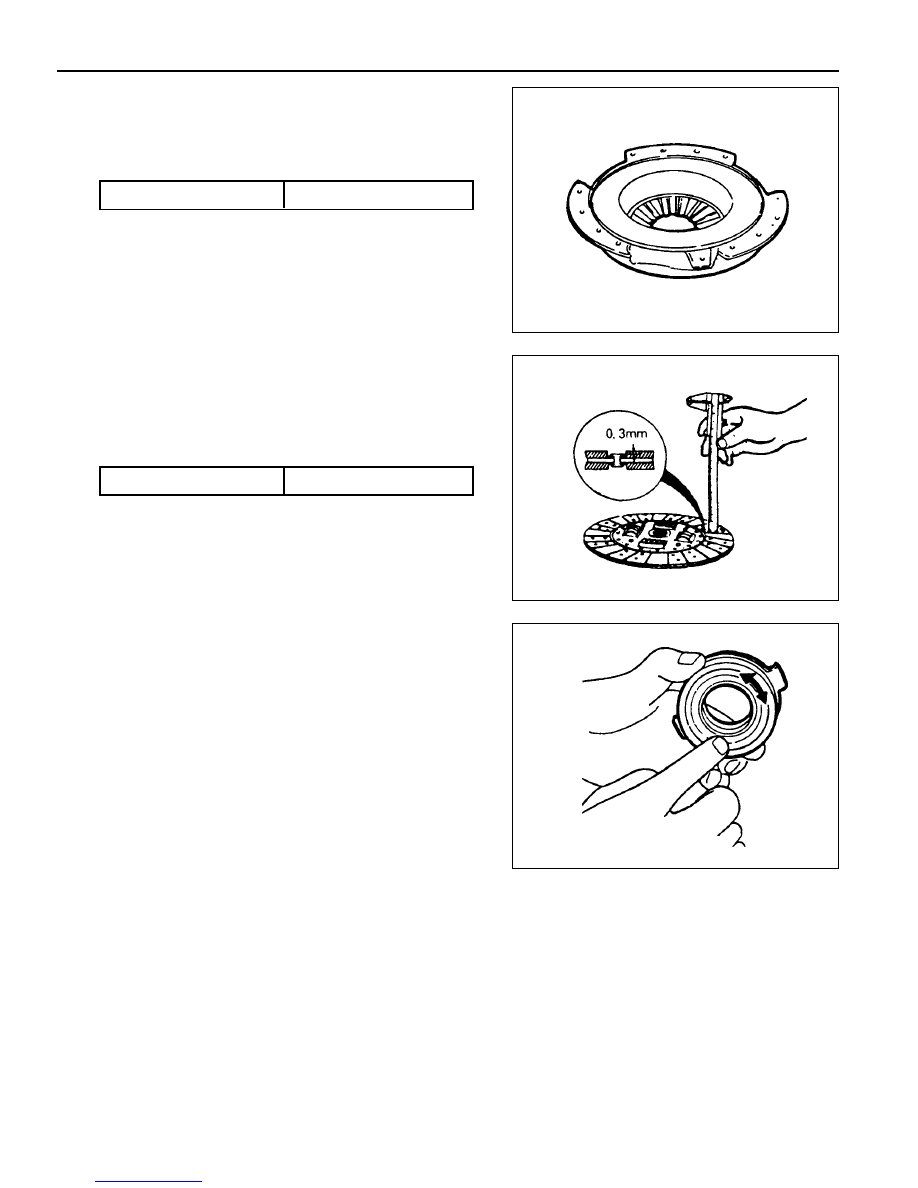

1. Clutch Cover

l

Check the diaphragm spring tip for wear and height

unevenness.

l

Check the pressure plate surface for wear, crack and

discoloration.

l

Check the strap plate rivet for looseness and replace

the clutch cover if loosened.

Unevenness Limit

0.8 mm

2. Clutch Disc

l

Check the facing for rivet looseness, excessive runout,

sticks, oil and grease.

l

Measure the rivet head depth.

If out limit, replace the disc.

3. Clutch Release Bearing

l

The release bearing is permanently lubricated and

requires no cleaning.

l

Check the bearing for sticks, damage, abnormal noise,

turning drag and wear.

4. Release Fork

l

If there is abnormal wear in contact point with bearing,

replace the release fork.

Wear Limit

0.3 mm