Daewoo Musso. Manual - part 191

1F3-44 OM600 ENGINE CONTROLS

Tools Required

617 589 09 21 00 Rl Sensor

617 589 10 21 00 Timing Tester

667 589 00 21 00 TDC Pulse Generator

Commercial Tools

Item

Digital Tester

With Pulse Generator

Without Pulse Generator

Tools

Bosch, MOT 001.03

Hartmann & Braun, EOMT3

Bosch, ETD 019.00

Sun, DIT 9000

ALV, Diesel - Tester 875

Digital tester (RIV Method)

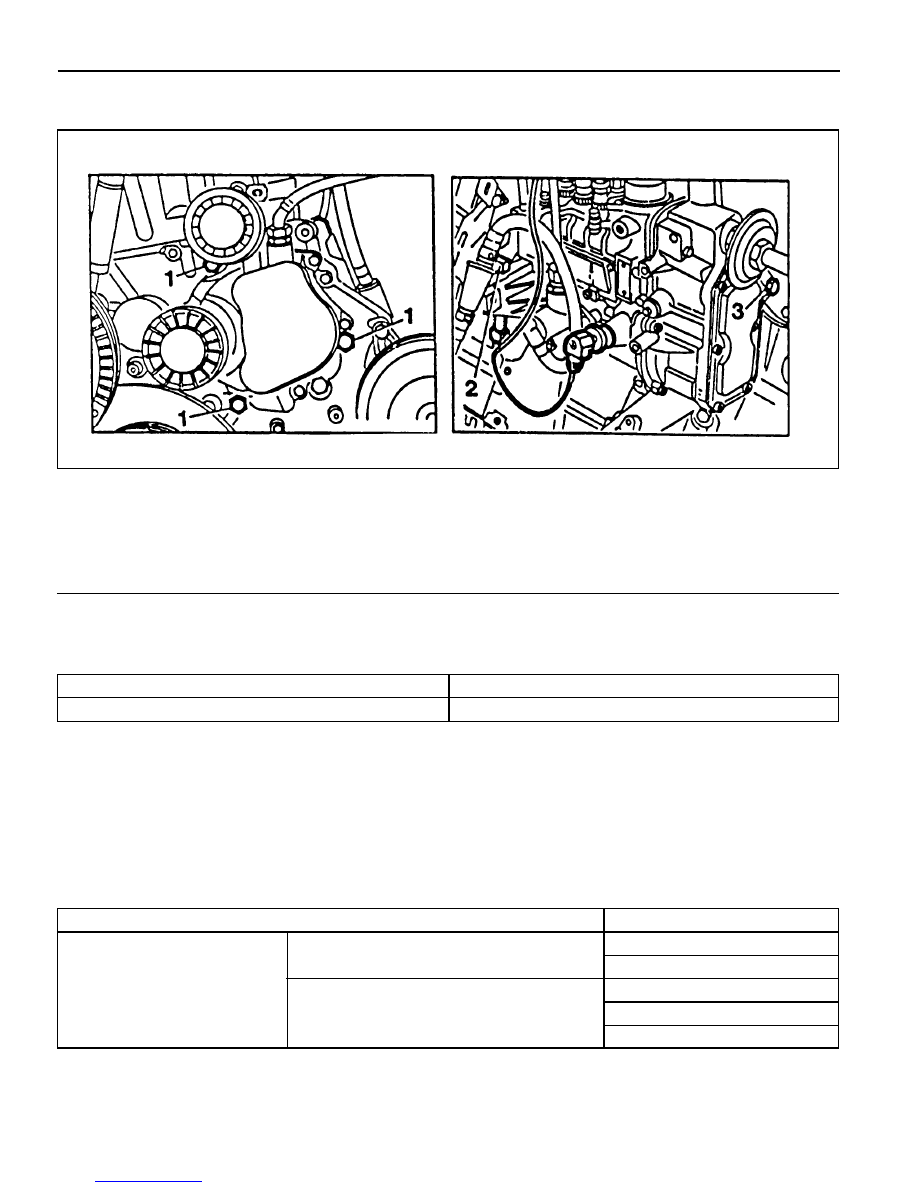

1 Bolt ............................................................ 23Nm

2 Adjusting

Screw ....... To the right : start of delivery retarded

To the left : start of delivery advanced

3 Bolt ............................................................ 23Nm

Service Data

Start of Delivery (RIV)

Ldling Speed

ATDC 14° - 16°

OM661LA : 720 - 820 rpm, OM662LA : 750 - 850 rpm