Daewoo Musso. Manual - part 190

1F3-40 OM600 ENGINE CONTROLS

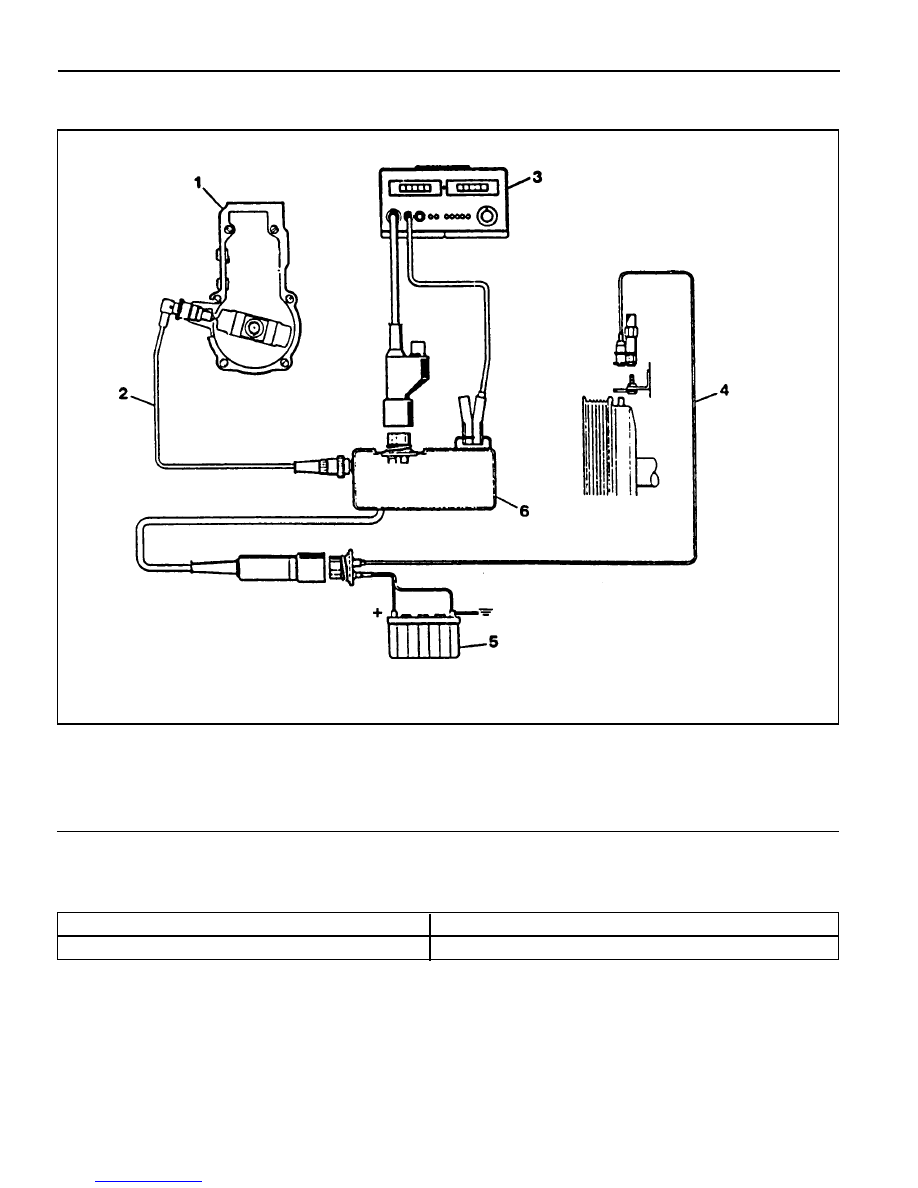

Start of Delivery (RIV)

Idle Speed

(Connection Diagram for Testers With Adapter)

1 Fuel Injection Pump

2 Rl Sensor

3 Digital Tester

4 TDC Pulse Sender Unit

5 Battery

6 Rl Pulse Generator

Service Data

ATDC 14° - 16°

OM661LA : 720 - 820 rpm, OM662LA : 750 - 850 rpm