Daewoo Musso. Manual - part 27

1B1-44 M162 ENGINE MECHANICAL

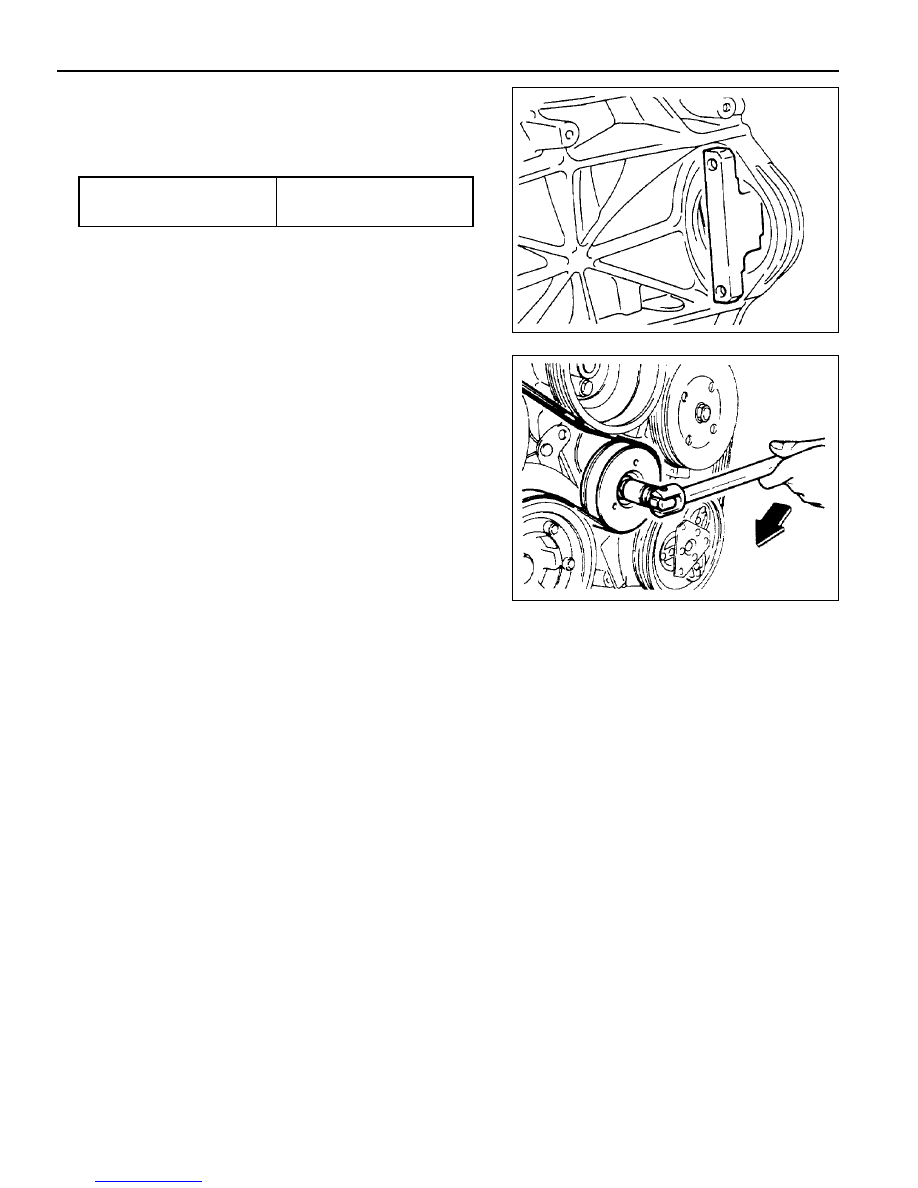

Engine Lock 602 589 00 40 00

2. Remove the start motor and install the engine lock to the

flywheel ring gear.

3. Remove the center bolt.

Installation Notice

Tightening Torque

1st step 200 - 220 Nm

2nd step 90° +10°

4. Remove the vibration damper assembly using the puller.

5. Installation should follow the removal procedure in the

reverse order.

Notice

If possible, don’t separate the vibration damper and the

pulley.