Daewoo Matiz (2003 year). Manual - part 180

6D – 12 MANUAL STEERING GEAR

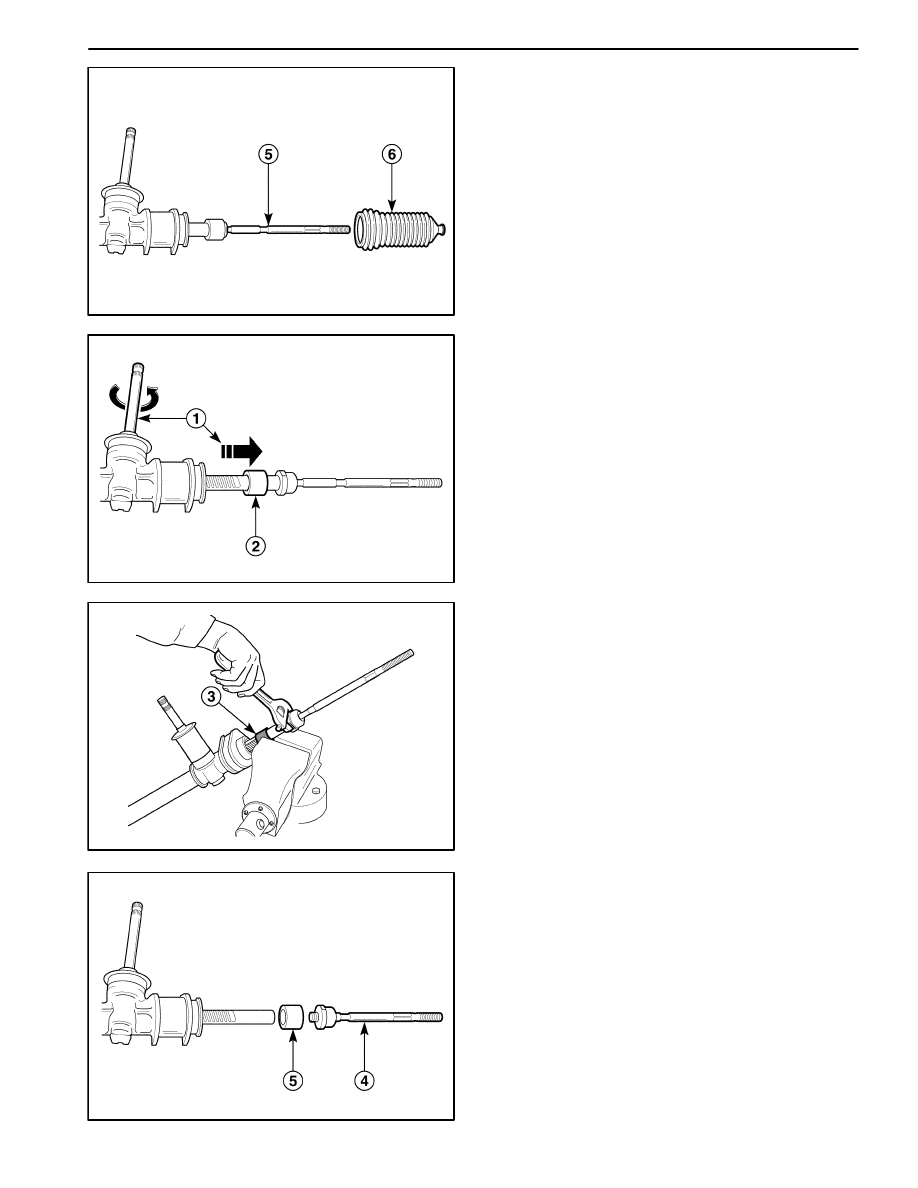

D105B704

D

Coat the greases on the tie rod (5).

D

Remove the rack and pinion boot (6).

D105B705

3. Remove the tie rod

D

Pull the rack gear perfectly from the steering gear

housing by turning the pinion gear (1).

D

Disconnect the shock damper ring from the tie rod

ball joint (2).

D15B706A

D

Vise the rack gear (3).

Important: Clothe the rack gear with a cloth before vis-

ing the rack gear.

Notice: Do not vise the rack gear over two teeth face.

D105B707

D

Remove the tie rod (4).

D

Remove the shock damper ring (5).