Daewoo Matiz (2003 year). Manual - part 170

5C – 8 CLUTCH

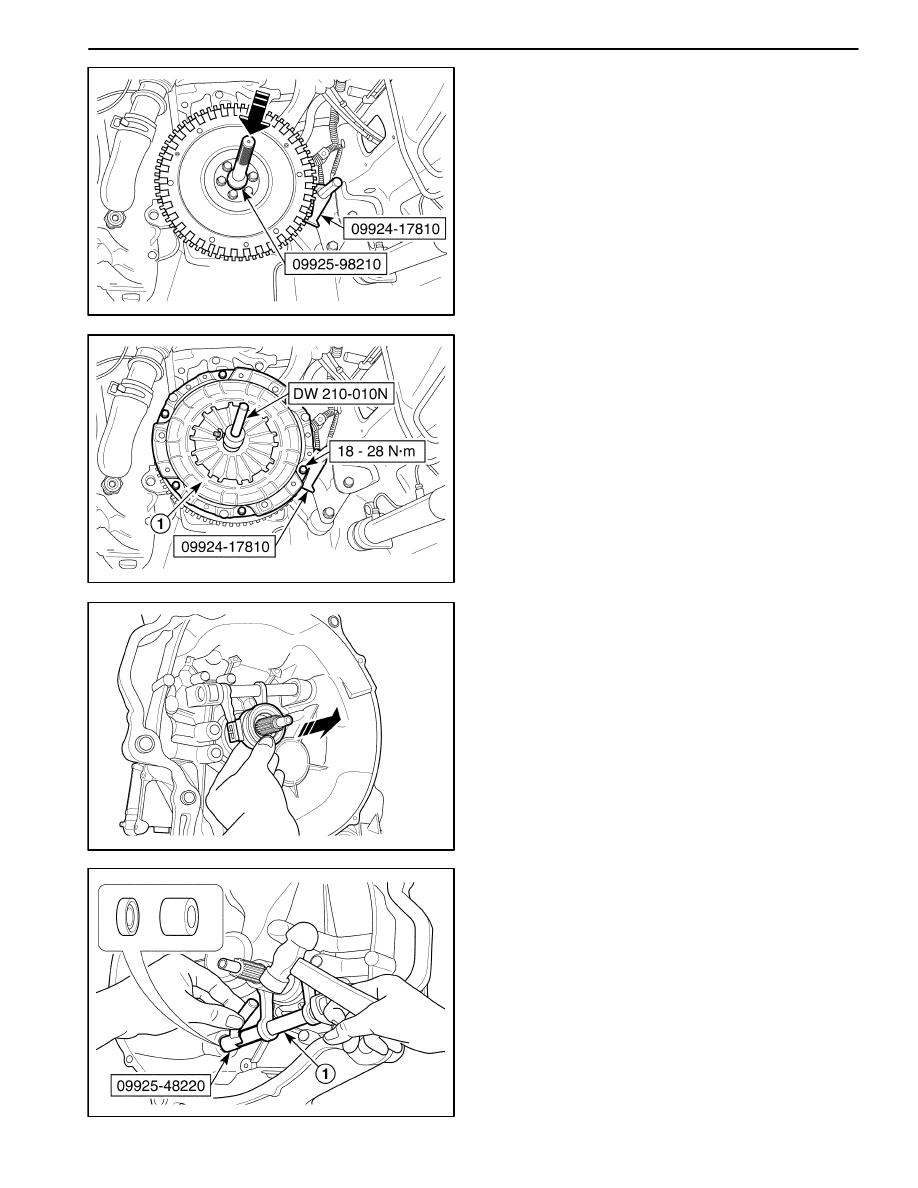

D13C5071

Installation Procedure

1. Install in the reverse order of removal.

2. Install the input shaft bearing using the input shaft

bearing installer 09925–98210 and the flywheel hold-

er 09924–17810.

D13C508B

3. Install the pressure plate and the clutch disc.

D

Install the clutch disc.

D

Install the pressure plate (1).

D

Align the pressure plate and the clutch disc onto the

flywheel using the clutch center guide DW210–010

and the flywheel holder 09924–17810.

D

Install the pressure plate bolts.

Tighten

Tighten the bolts to 18–28 N

S

m (13–21 lb-ft).

D103C510

D103C509

CLUTCH RELEASE BEARING, SHAFT

AND BUSHING

Tools Required

09923–46040

Bushing Joint Pipe

09925–48220

Bushing Remover/Installer

09930–30102

Sliding Shaft

09943–88211

Bushing, Bearing Installer

Removal Procedure

1. Remove the transaxle from the vehicle. Refer to Sec-

tion 5B, Manual Transaxle.

2. Remove the release arm. Refer to “Clutch Release

Arm” in this section.

3. Remove the release bearing.

4. Remove the release shaft and bushing.

D

Remove the bushing (No.2) and seal using the

bushing remover 09925–48220 and hammer.

D

Remove the release shaft (1).