Daewoo Matiz (2003 year). Manual - part 94

1F – 286 ENGINE CONTROLS

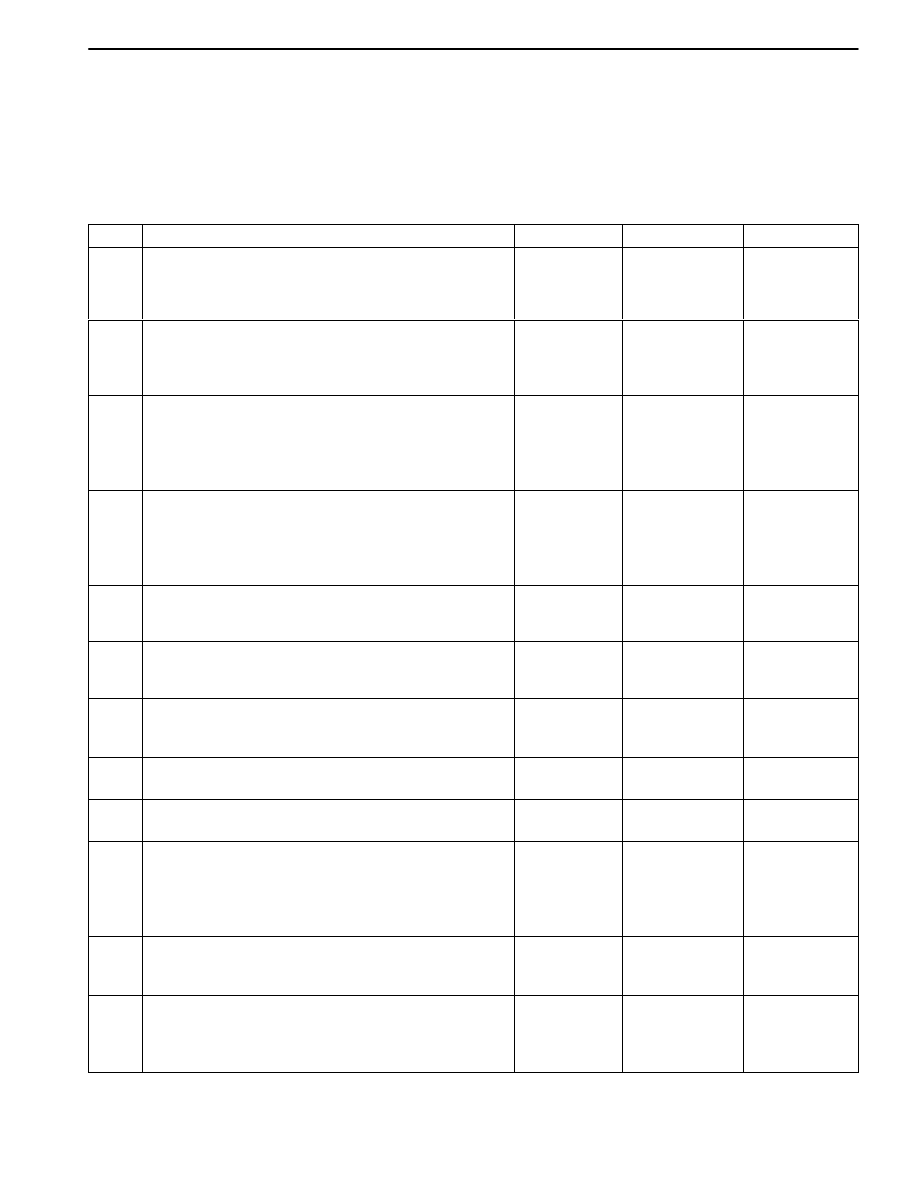

SURGES OR CHUGGLES

Definition: Engine power variation under steady throttle

or cruise. Feels like the vehicle speeds up and slows

down with no change in the accelerator pedal position.

Important: Make sure the driver understands A/C com-

pressor operation as described in the owner’s manual.

The speedometer reading and the speed reading on the

scan tool should be equal.

Before diagnosing the symptom, check service bulletins

for updates.

Step

Action

Value(s)

Yes

No

1

Were the Important Preliminary Checks performed?

–

Go to Step 2

Go to

“Important

Preliminary

Checks”

2

Connect the scan tool to the Data Link Connector

(DLC).

Does the oxygen sensor (O2S) respond quickly to

different throttle positions?

–

Go to Step 4

Go to Step 3

3

1. Check the O2S for silicone or other contaminants

from fuel or use of improper Room Temperature

Vulcanizing (RTV) sealant.

2. Replace the contaminated O2S.

Is the repair complete?

–

System OK

–

4

1. Drive the vehicle at the speed of the complaint.

2. Monitor the long term fuel trim reading using the

scan tool.

Is the long term fuel trim reading within the value

specified?

–20–25%

Go to Step 7

Go to Step 5

5

Is the long term fuel trim reading below the value

specified?

–20%

Go to

“Diagnostic Aids

for DTC P0172”

Go to Step 6

6

Is the long term fuel trim reading above the value

specified?

25%

Go to

“Diagnostic Aids

for DTC P0171”

–

7

Check the fuel system pressure while the condition

exists.

Is the fuel system pressure within specifications?

380 kPa

(55 psi)

Go to Step 8

Go to Step 17

8

Check the in-line fuel filter.

Is the filter dirty or plugged?

–

Go to Step 18

Go to Step 9

9

Perform an injector diagnosis.

Did the injector diagnosis pinpoint the problem?

–

Go to Step 19

Go to Step 10

10

1. Check for proper ignition voltage output using a

spark tester.

2. Inspect the spark plugs for cracks, wear, improper

gap, burned electrodes, or heavy deposits.

Is the problem found?

–

Go to Step 11

Go to Step 12

11

Repair or replace any ignition system components

as needed.

Is the repair complete?

–

System OK

–

12

1. Inspect the ECM grounds for being clean, tight,

and in their proper locations.

2. Inspect the vacuum lines for kinks or leaks.

Is the problem found?

–

Go to Step 13

Go to Step 14