Daewoo Matiz (2003 year). Manual - part 29

1F – 26 ENGINE CONTROLS

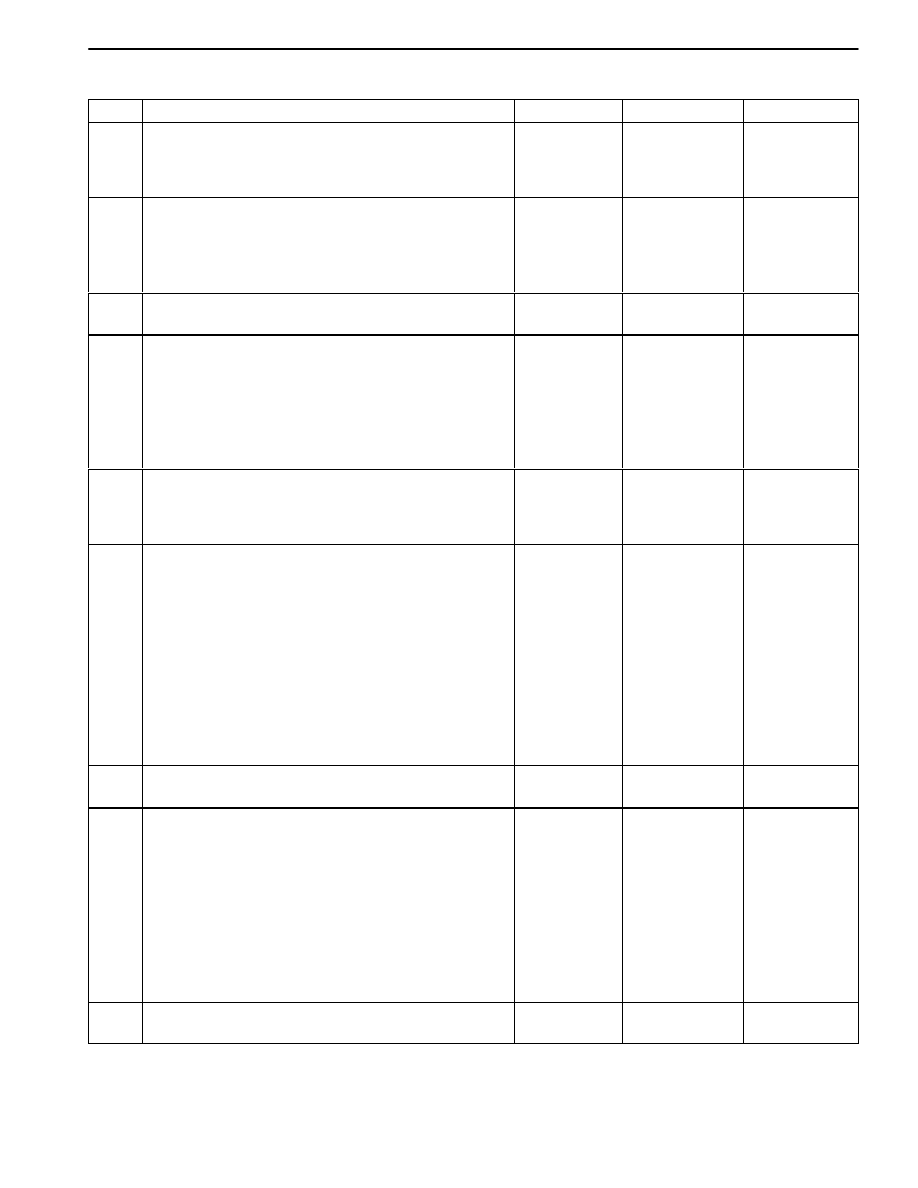

Engine Cranks But Will Not Run (Cont’d)

Step

Action

Value(s)

Yes

No

12

Check for an open or short in the wires between

CKP sensor connector and ECM connector and

repair as need.

Is the repair complete?

–

Go to Step 2

–

13

1. Disconnect electronic Ignition (EI) system ignition

coil connector to prevent the vehicle from starting.

2. Measure the voltage at ECM connector terminal

24 and 54 by backprobing the ECM connector.

Are the voltage readings near the value specified?

0.4 V with

ignition ON,

2.0 V during

cranking

Go to Step 15

Go to Step 14

14

Replace the CKP sensor.

Is the repair complete?

–

Go to Step 2

–

15

1. Turn the ignition OFF.

2. Disconnect the electrical connector at EI system

ignition coil.

3. Connect a test light between terminal 1 of the EI

system ignition coil connector and ground.

4. Turn the ignition ON.

Is the test light on?

–

Go to Step 17

Go to Step 16

16

Check for open in wire between the battery and EI

system ignition coil connector terminal 1 and repair

as needed.

Is the repair complete?

–

Go to Step 2

–

17

1. Turn the ignition OFF.

2. Disconnect ECM connector and EI system

ignition coil connector.

3. Measure the resistance between following

terminals:

D

Terminal 2 of ignition coil and terminal 1 of

ECM connector.

D

Terminal 3 of ignition coil and terminal 32 of

ECM connector.

D

Terminal 4 of ignition coil and terminal 31 of

ECM connector.

Are the resistance within the value specified?

0

Ω

Go to Step 19

Go to Step 18

18

Check for open circuit and repair as needed.

Is the repair complete?

–

Go to Step 2

–

19

1. Measure the resistance between following

terminals:

D

Terminal 1 and 2 of ignition coil.

D

Terminal 3 and 4 of ignition coil.

Are the resistance within the value specified?

2. Remove the high tension cable.

3. Measure the resistance between second coil.

D

Between 1 and 4

D

Between 2 and 3

Are the resistance within the value specified?

0.9

Ω

5.3 k

Ω

Go to Step 21

Go to Step 20

20

Replace the EI system ignition coil.

Is the repair complete?

–

Go to Step 2

–