DAF LF45, LF55 Series. Manual - part 650

©

200515

3-29

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΛΦ45/55 series

5

3.36 CHECKING AUTOMATIC GEARBOX OIL LEVEL

Checking cold oil level

1.

Place the vehicle on a flat and level surface.

2.

Make sure that the gearbox is in neutral and

allow the engine to run for several minutes.

3.

Apply the service brake, switch the gearbox

to D, then to N and finally switch the gearbox

to R. The purpose of this is to fill the hydraulic

system.

4.

Switch the gearbox to the parking position

and release the service brake.

5.

Remove the dipstick when the engine is

idling and wipe it clean with a lint-free cloth.

Note:

To take the dipstick out of the holder, the

sealing cap must be held while the dipstick is

turned anti-clockwise.

6.

Put the dipstick back.

7.

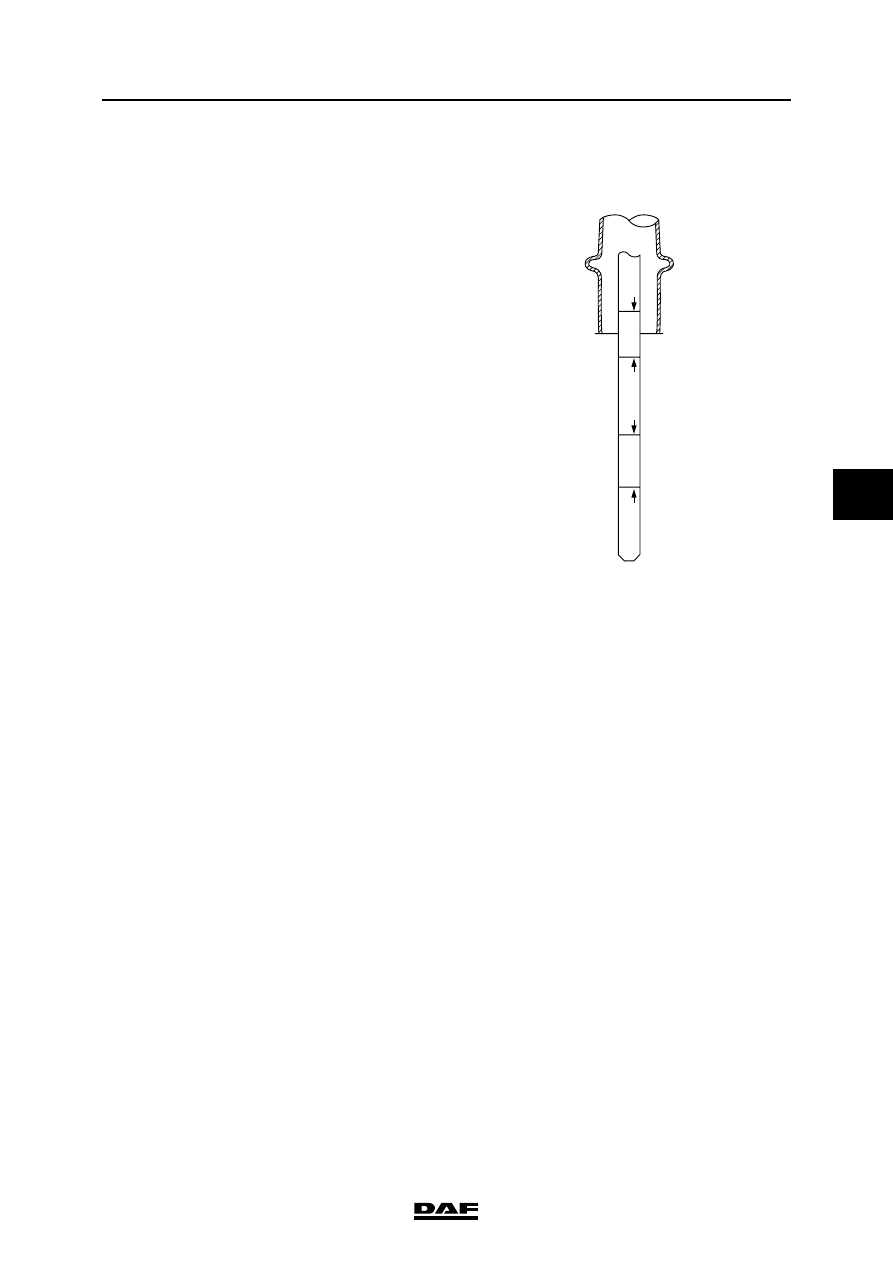

Remove the dipstick and check the oil level.

The oil level should be between the "Cold

add" and "Cold full" marks.

8.

Clean the dipstick with a lint-free cloth and

put it back.

9.

Remove the dipstick and check the oil level

again.

10. Oil needs to be added when the oil level is

below the "Cold add" mark.

11. Check the oil level in the gearbox at

operating temperature.

HOT

FULL

COLD

FULL

HOT

ADD

COLD

ADD

W 3 03 099