DAF LF45, LF55 Series. Manual - part 644

©

200515

3-5

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΛΦ45/55 series

5

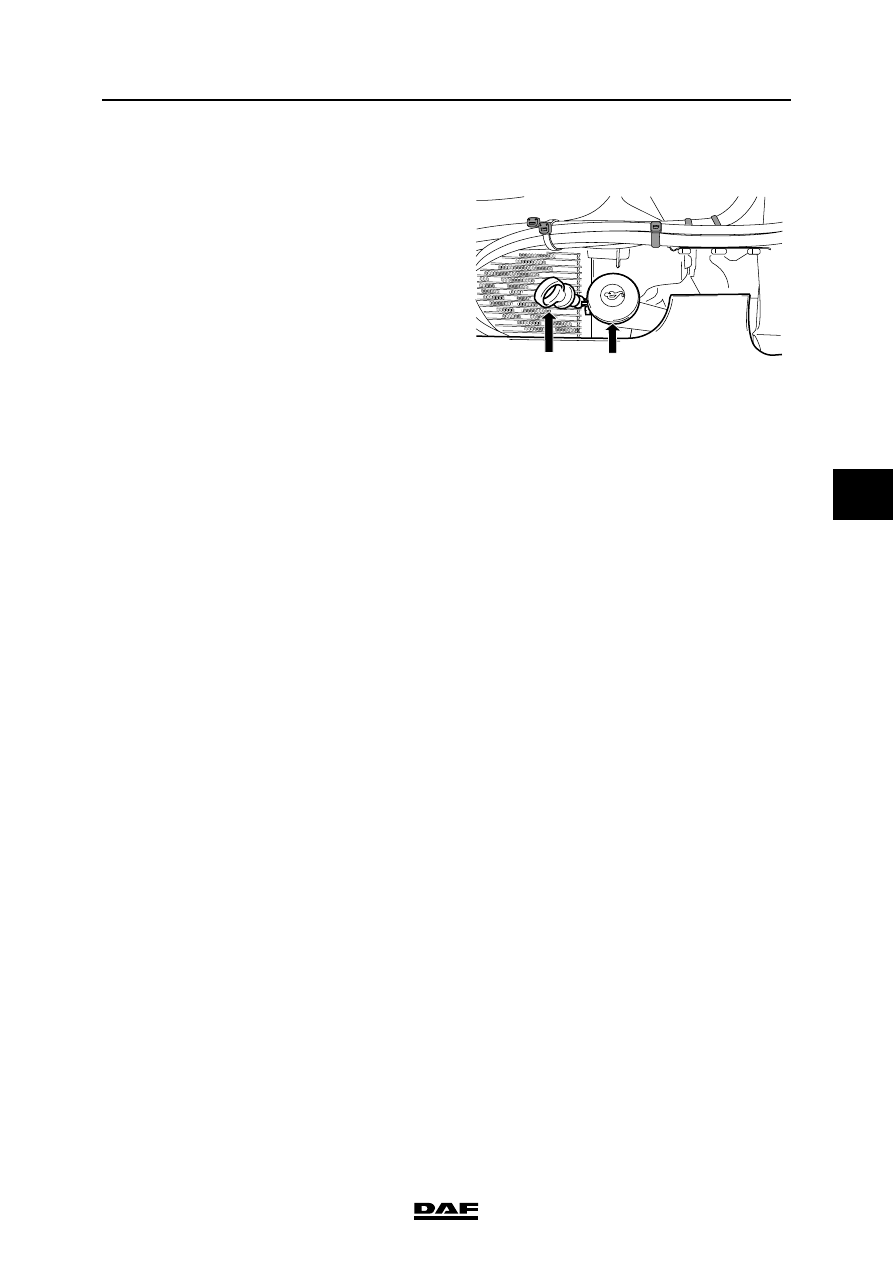

3.8 CHECKING THE ENGINE OIL LEVEL

1.

Ensure that the vehicle is entirely horizontal.

2.

Pull the dipstick (2) out of the holder.

3.

Wipe the dipstick clean with a lint-free cloth.

4.

Put the dipstick back into the holder.

5.

Pull the dipstick out again and check the oil

level.

Note:

It takes approx. 20 minutes for all the oil to

run into the sump when the engine is "warm".

If the dipstick is checked immediately after

switching the engine off or immediately after

oil has been added, the level shown on the

dipstick will be too low.

6.

Fill oil through the filler opening (1) until the

oil level reaches the maximum mark. See

"Draining and filling". Always use the

specified oil. Do not top up above maximum

level.

Note:

For the difference between minimum and

maximum engine oil level, see "Technical

data".

2

1

G0 00 212