DAF LF45, LF55 Series. Manual - part 316

©

200416

4-7

Inspection and adjustment

CE ENGINE FUEL SYSTEM

ΛΦ45/55 series

4

5

7.

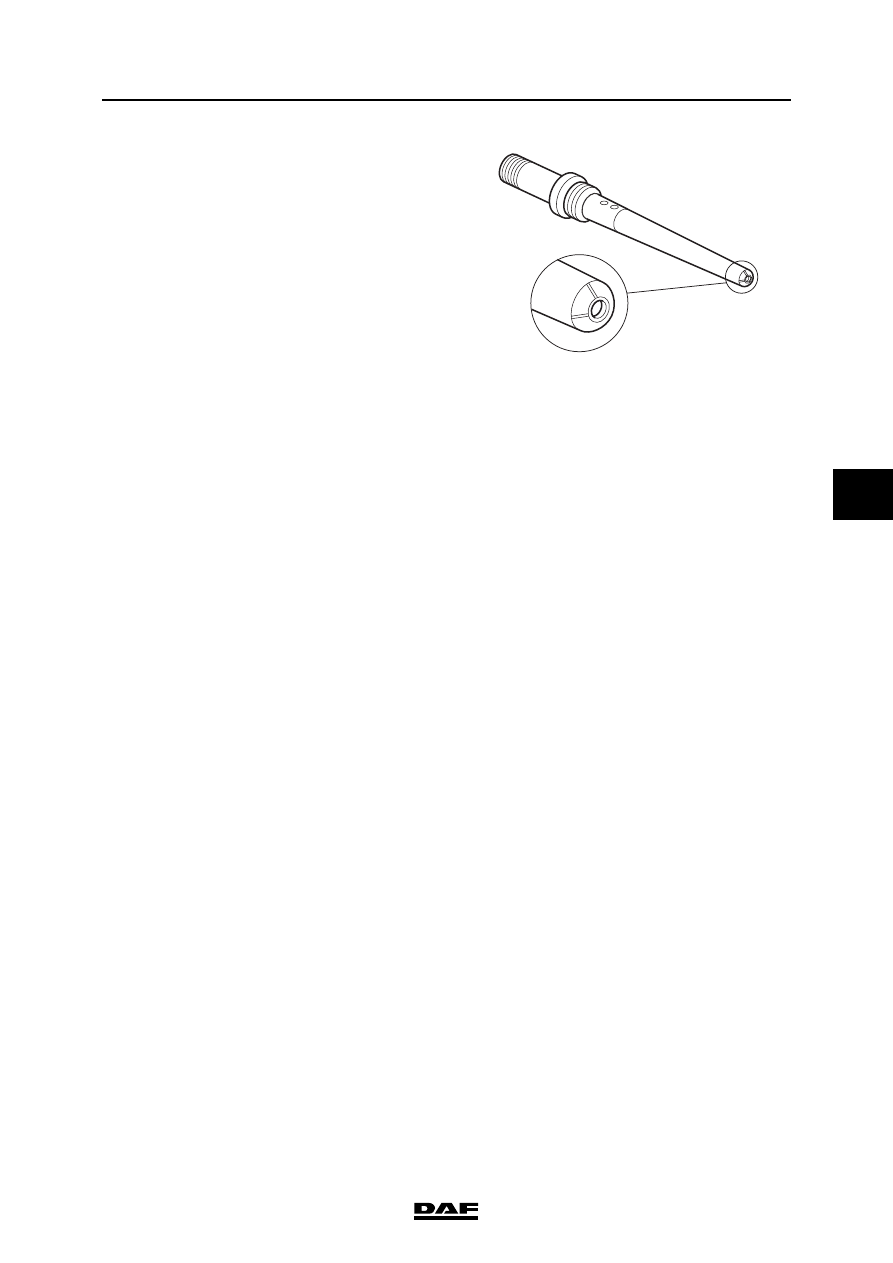

Check the fuel supply pipe for damage and

signs of leakage.

Leakage in the fuel supply pipe can be

recognised by erosion tracks (lines) on the

nose of the supply pipe. If necessary or if in

doubt, replace the fuel supply pipe.

8.

Check that the injector fuel connection is not

leaking.

Leakage in the injector fuel connection can

be recognised by erosion tracks (lines) in the

socket of the fuel connection . If necessary or

if in doubt, replace the injector.

Note:

If fuel has been found in the lubricating oil,

extra attention must be paid to the O-rings of

the injectors, as these have most probably

been damaged by increased pressure in the

return circuit as a result of an internal leak.

Note:

The following guidelines must be adhered to:

-

If the injector is defective, both the injector

and the fuel supply pipe must be replaced.

-

If the fuel supply pipe is defective and in

addition the sealing surface with the injector

is damaged, both the injector and the fuel

supply pipe must be replaced.

-

If the fuel supply pipe is defective and the

sealing surface with the injector is not

damaged, the fuel supply pipe must be

replaced but the injector can be reused.

9.

Fit the injector and fuel supply pipe. See

"Removal and installation".

10. Again inspect for internal fuel leaks to check

that there is no leakage.

i400776