DAF LF45, LF55 Series. Manual - part 314

©

200416

3-5

Description of components

CE ENGINE FUEL SYSTEM

ΛΦ45/55 series

4

5

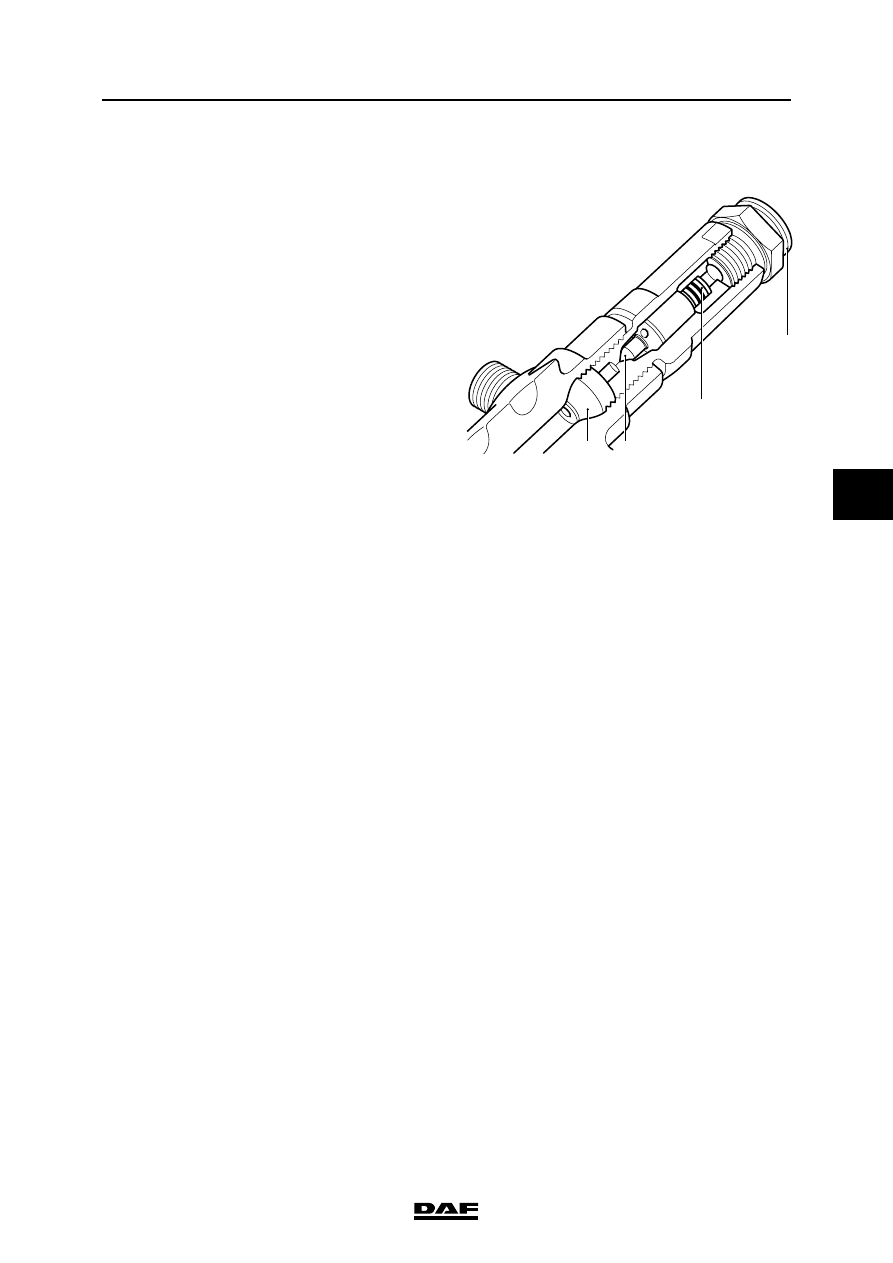

3.4 FUEL RAIL PRESSURE-LIMITING VALVE

The fuel rail has a pressure-limiting valve so that

the rail pressure is maintained at a safe value in

emergency situations.

The fuel rail pressure control circuit is normally

active. This consists of the fuel lift pump, fuel

pump control solenoid valve, high-pressure

pump, fuel rail, rail pressure sensor and

electronic unit. If a fault occurs, the rail pressure

can no longer be controlled. This can rise to the

actuating pressure of the fuel rail pressure-

limiting valve. This pressure is approx. 1650 bar.

In the open position all surplus fuel flows without

pressure to the fuel tank return connection.

The valve includes a sealing cone (1), a valve

body (2), a spring (3) and a return connection with

quick-release coupling (4).

i400592

1

2

3

4