DAF LF45, LF55 Series. Manual - part 303

©

200416

3-3

Inspection and adjustment

BE ENGINE INLET/EXHAUST SYSTEM

ΛΦ45/55 series

4

3

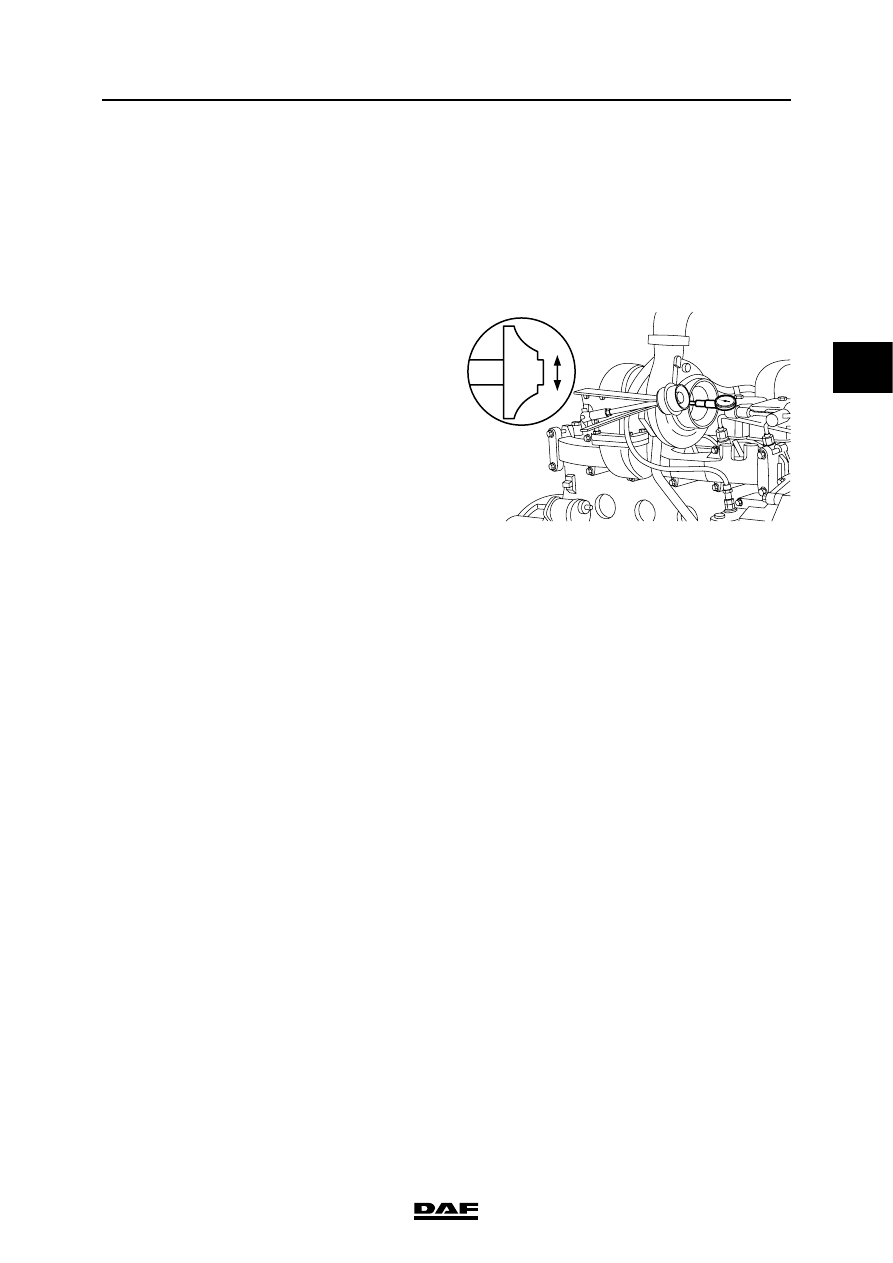

3.3 INSPECTING TURBOCHARGER RADIAL BEARING PLAY

Note:

The turbocharger radial bearing play should only

be checked when the engine is cold.

1.

Remove the turbocharger from the exhaust

manifold. See "Removal and installation".

2.

Fit a pressure gauge to the turbocharger

housing and measure the radial play.

Compare the reading with the specified

value; see "Technical data". Replace the

turbocharger if necessary.

3.

Fit the turbocharger. See "Removal and

installation".

i400650