DAF LF45, LF55 Series. Manual - part 276

©

200508

4-7

Demounting and mounting

PROP SHAFTS

ΛΦ45/55 series

3

10

5.

Push the spider down again in the direction

of the shaft fork. Again, continue until the

spider touches the fork.

6.

The spider and the drive flange can now be

tipped out of the shaft fork.

7.

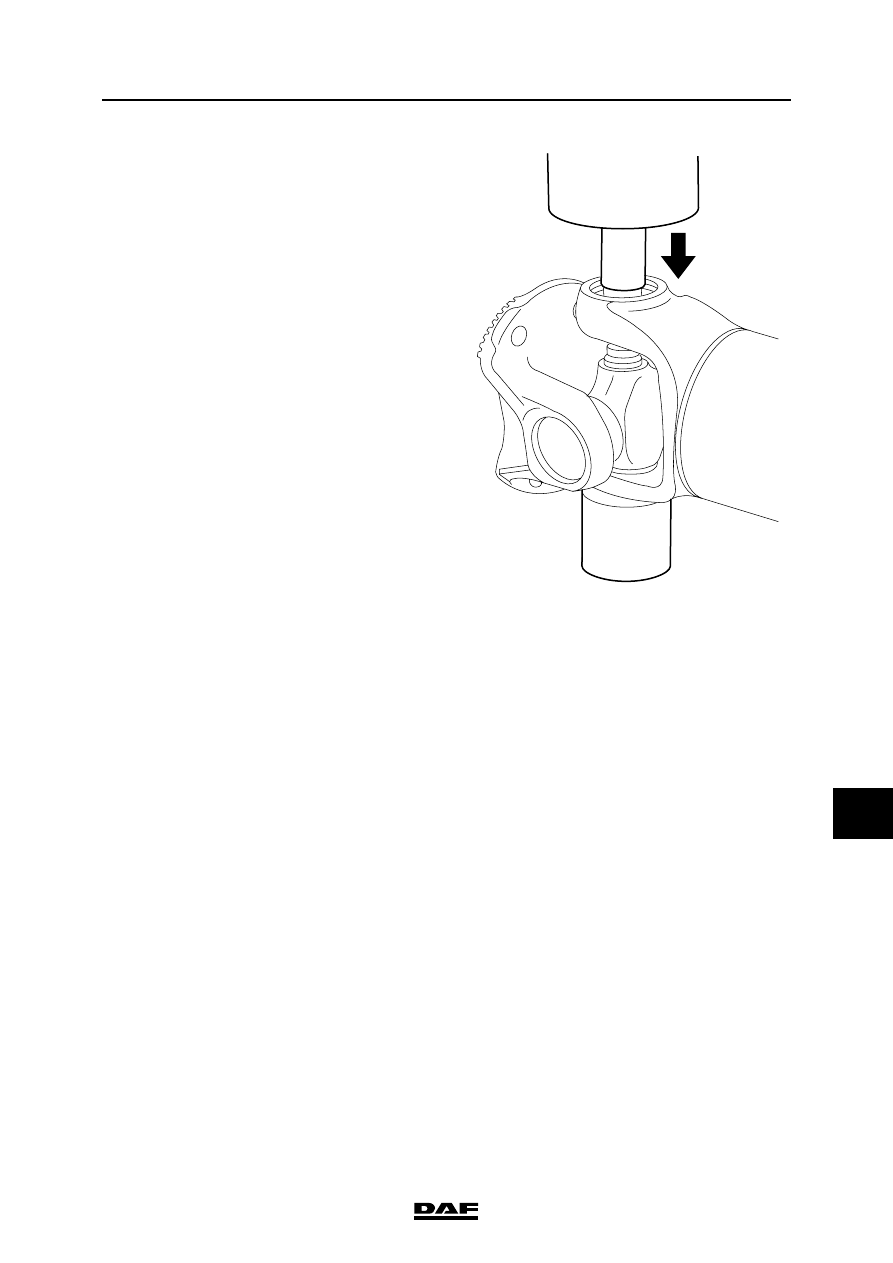

Place the drive flange on a bush underneath

a press and press the entire spider including

bearings and drive flange down, until the

spider touches the fork of the drive flange.

8.

Rotate the drive flange 180

″ and remove the

bearing that has just been pressed out.

Place the drive flange back on the bush.

9.

Push the spider down again in the direction

of the shaft fork. Again, continue until the

spider touches the fork.

10. The spider can now be tipped out of the drive

flange fork.

Note:

When spiders are being replaced, always

replace them including their bearings.

11. Check the components to be reused for any

cracks and/or damage.

Assembly, universal joint

Note:

After assembly, it must be possible to move

the drive flanges and spiders by hand. When

mounting the spider, Seeger rings of the

same thickness must be used.

1.

Install the sealing rings in their proper

positions on the bearings and lubricate them

lightly so that the needles remain in place.

2.

Press one bearing partly into the drive

flange.

W306011-2