DAF LF45, LF55 Series. Manual - part 274

©

200508

3-1

Removal and installation

PROP SHAFTS

ΛΦ45/55 series

3

10

3. REMOVAL AND INSTALLATION

3.1 REMOVING AND INSTALLING SPICER PROP SHAFT/INTERMEDIATE SHAFT

ASSEMBLY

Removing prop shaft/intermediate shaft

assembly

Note:

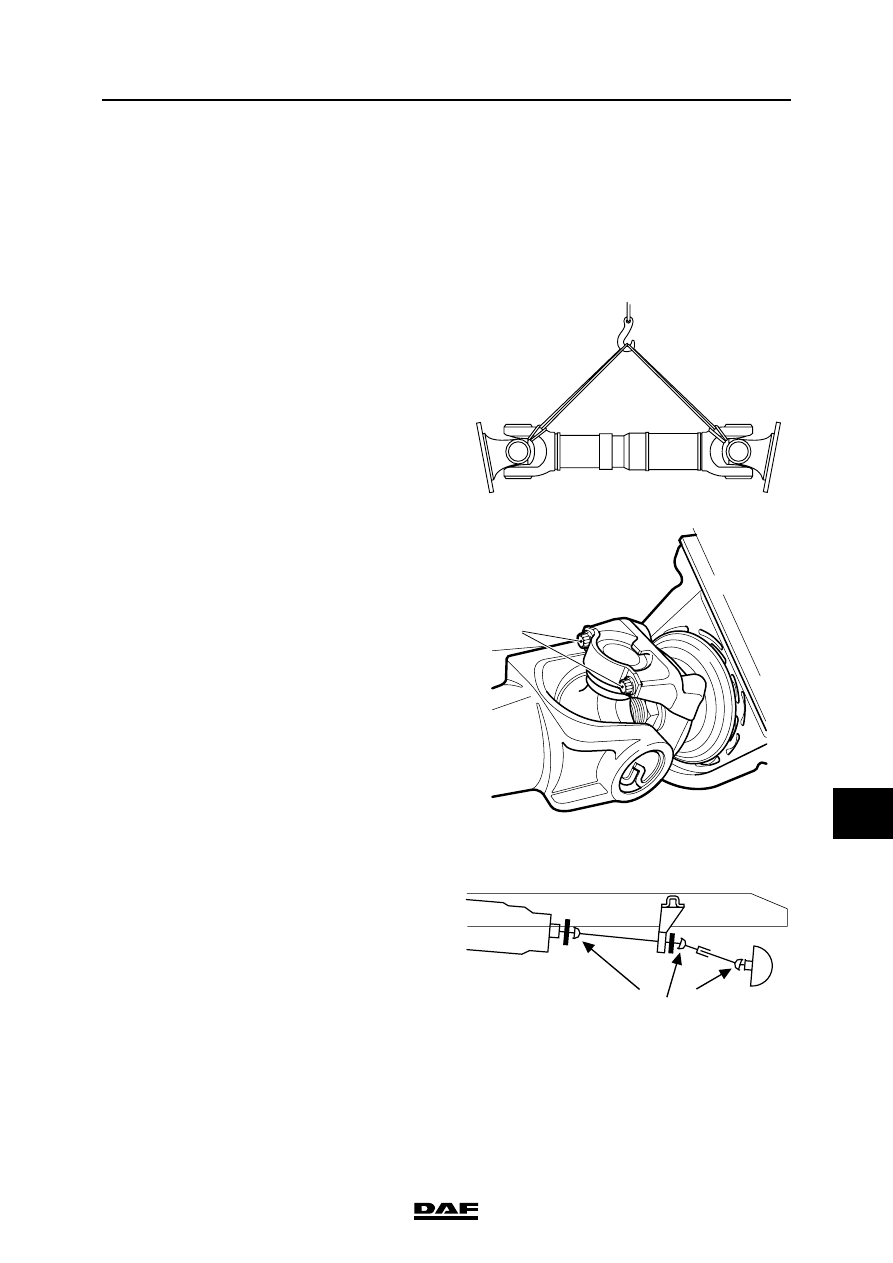

When removing one of the shafts in vehicles with

multiple shafts (prop shaft and intermediate

shafts), the other shaft must be tied to the chassis

or intermediate beam in such a way that it does

not obstruct the various operations. Always

transport and store shafts horizontally to avoid

damage and subsequent imbalance. Support the

shaft in at least two places. If possible, hang the

shaft in a hoist, using two sturdy ropes.

1.

Remove the attachment bolts from the

flanges and/or clamping pieces (1), and

carefully lower the shaft to the ground.

2.

Now remove the shaft from under the

vehicle.

Installing prop shaft/intermediate shaft

assembly

Note:

After repairs have been carried out or a shaft has

been replaced, the forks of all shafts must be

aligned.

1.

Fit the shaft under the vehicle. Use a hoist if

possible.

2.

Fit the attachment bolts. Tighten the

attachment bolts to the specified torque. See

"Technical data".

W 3 06 016

V3 00 377

1

=

=

W 3 06 019