DAF LF45, LF55 Series. Manual - part 245

©

200508

1-1

General

ZF 6S-850 GEARBOX

ΛΦ45/55 series

3

5

1. GENERAL

1.1 GENERAL

Gearbox type

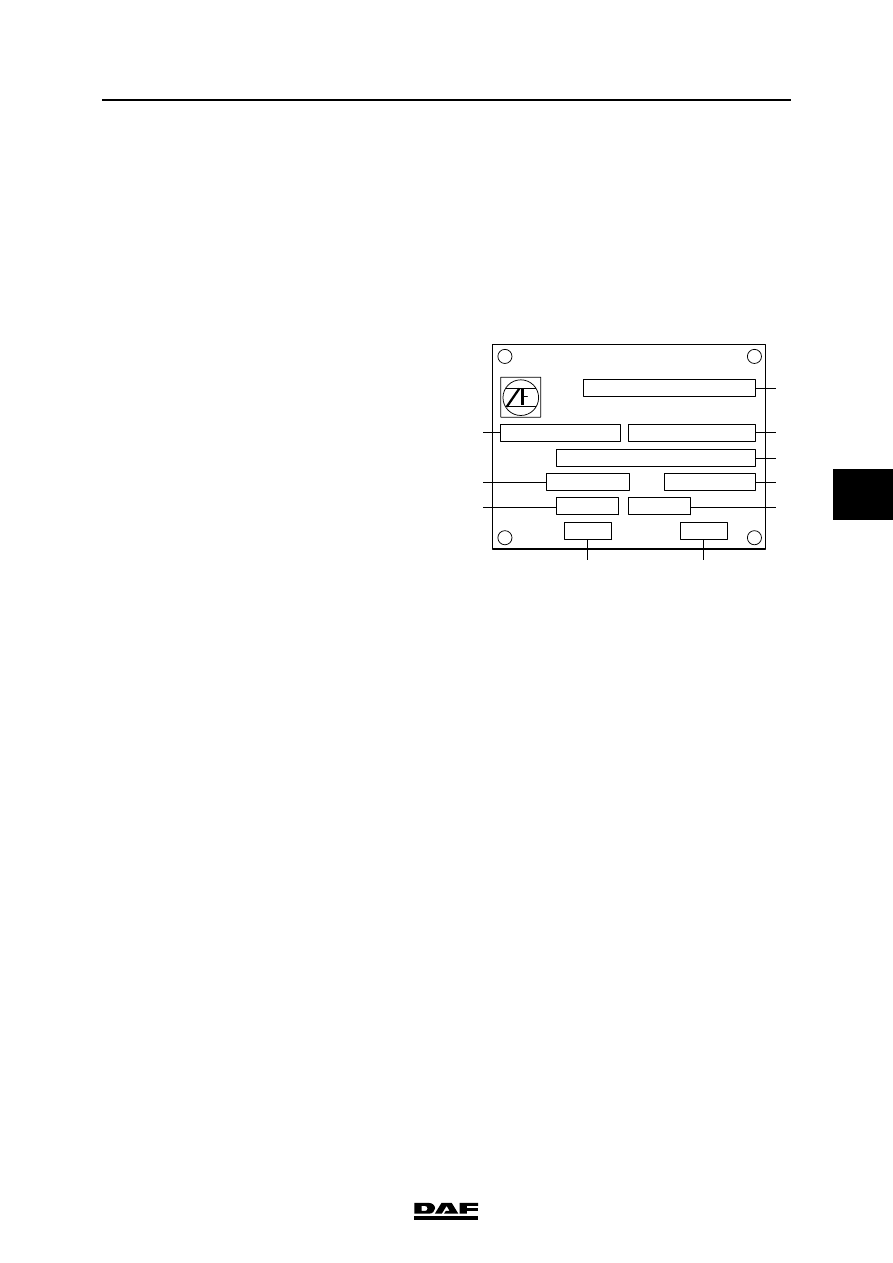

Each gearbox has a type plate attached to it,

indicating the type of gearbox. You can also find

this data on the identity card for the vehicle

concerned.

ZF gearbox type plate

V300049

1

2

4

5

3

8

6

7

10

9

1.

Type of gearbox

2.

Serial no. (ZF)

3.

Parts list (ZF)

4.

Specification no.

5.

Pulse generator ratio

6.

Gearbox ratio

7.

Engine speed using PTO

8.

PTO speed

9.

Gearbox oil capacity

10.

Oil specification