DAF LF45, LF55 Series. Manual - part 166

©

200505

3-11

Checking and adjusting

BE ENGINE

ΛΦ45/55 series

2

2

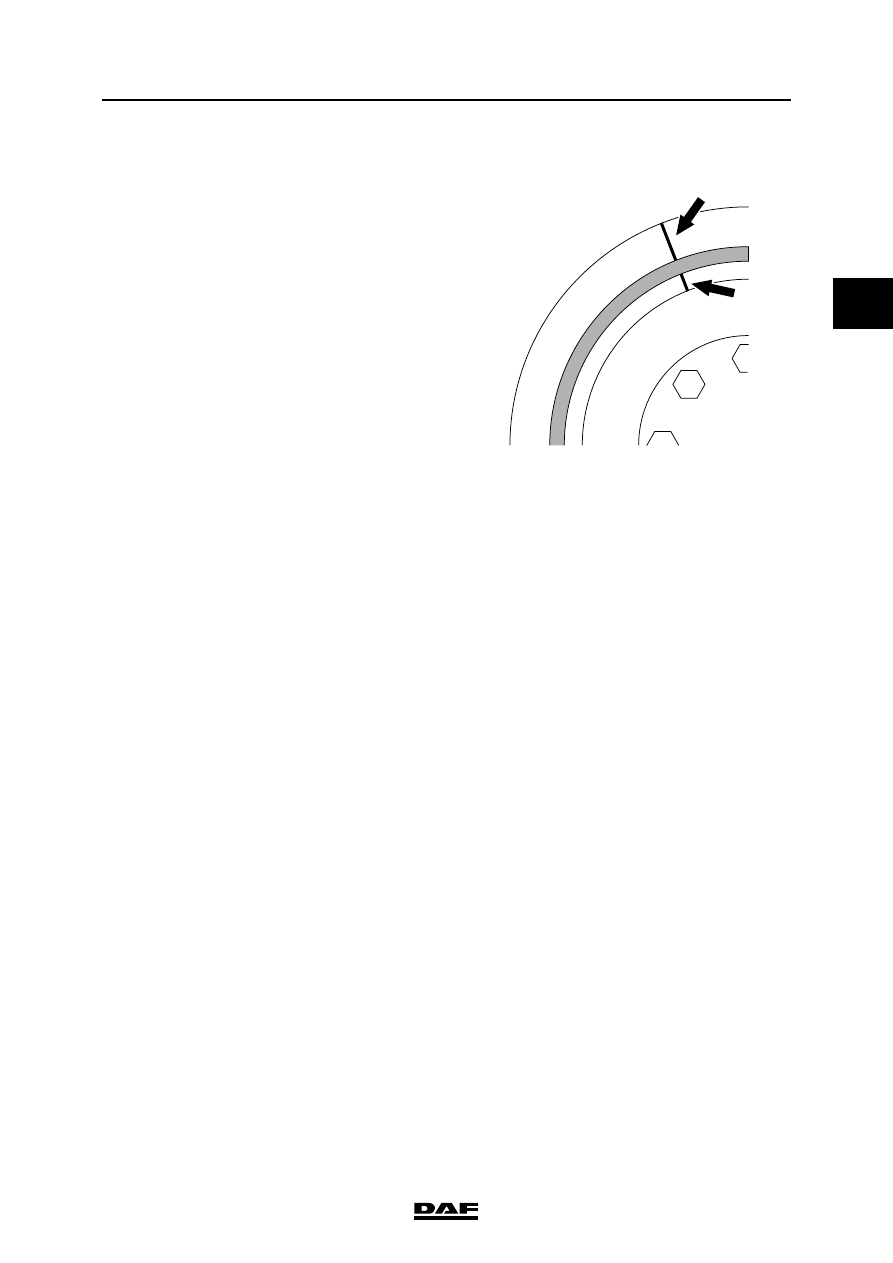

3.7 INSPECTION, VIBRATION DAMPER

1.

Check the reference lines. The reference

lines should form a single line.

2.

Inspect the rubber part for damage or

degradation. If the rubber part shows cracks

or if there are bits of rubber missing, the

vibration damper must be replaced.

3.8 INSPECTING THE CYLINDER HEAD

1.

Check the sealing plugs and expansion

plugs of the cylinder head for leaks. If

necessary, pressure-test the cylinder head.

2.

Inspect the cylinder head for damage to the

sealing surface and any cracks.

3.

Check the cylinder head for smoothness

using a straight edge and feeler gauge. See

"Technical data".

Note:

The cylinder head must be replaced if it does

not meet the specified values.

G0 00 199