Chery Tiggo 5 (T21). Manual - part 348

31–

96

31

A/C High Pressure Line

Removal

1. Recover the refrigerant from the A/C system (

).

2. Turn off all the electrical equipment and ignition switch.

3. Disconnect the negative battery cable.

4. Remove the front bumper assembly (

).

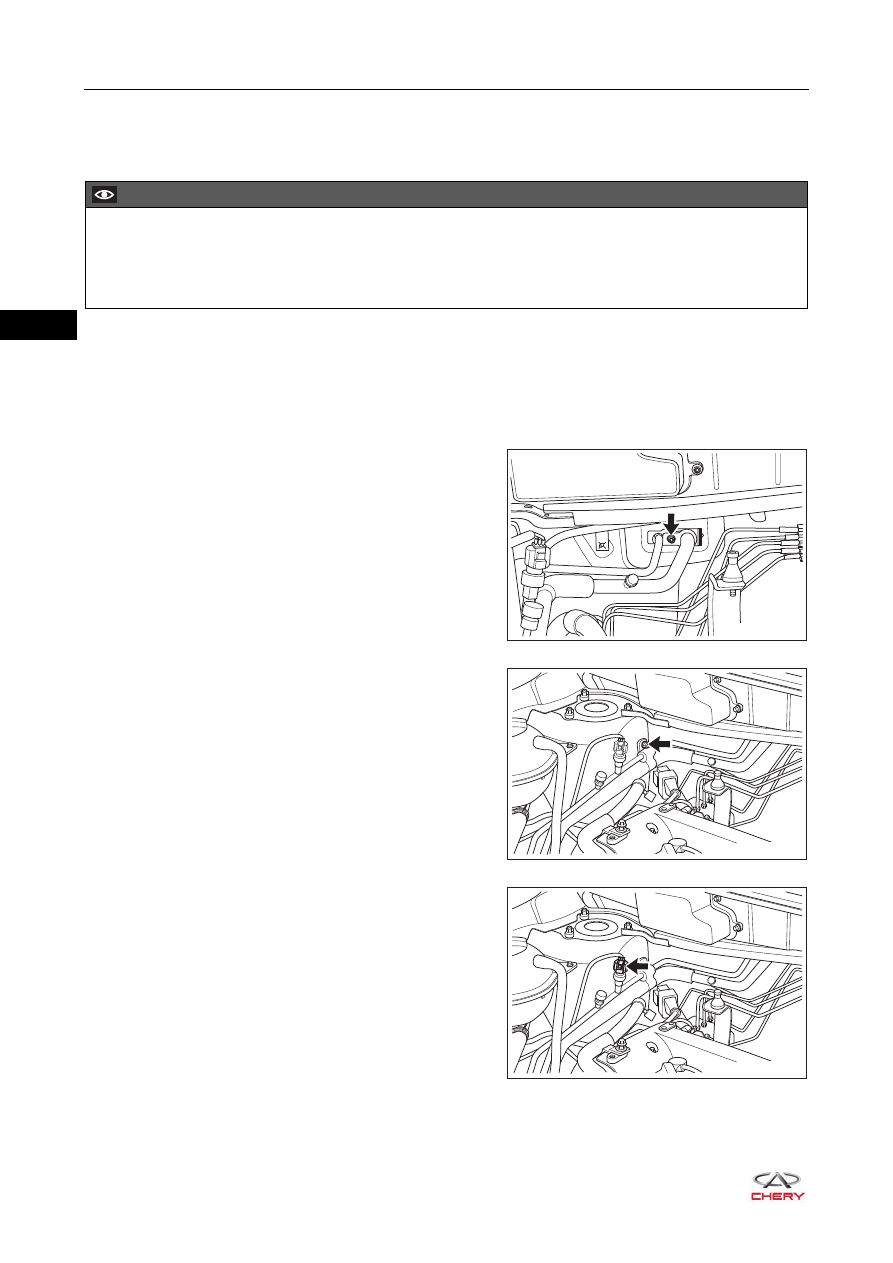

5. Remove the A/C high pressure line I (compressor to evaporator).

a. Remove the fixing bolt (arrow) between A/C high/low

pressure line and expansion valve, and disengage the

A/C high pressure line I.

(Tightening torque: 7 ± 1 N·m)

b. Remove the coupling nut (arrow) between A/C high/

low pressure line fixing bracket and body, and

disengage the A/C high pressure line I.

(Tightening torque: 7 ± 1 N·m)

c. Disconnect the A/C pressure sensor wire harness

connector (arrow).

CAUTION

Special service equipment for R134a refrigerant must be used to recover/charge refrigerant.

Always keep the work area in good ventilation.

The disconnected A/C line and connecting part should be sealed to prevent foreign matter from entering.

RT21310260

RT21310750

RT21310790