Chery Tiggo 5 (T21). Manual - part 341

31–

68

31

10.Remove the connecting pipe for refrigerant charging after the test is completed.

11.Reinstall the cover onto the A/C line joint.

Refrigerant Oil Recovering

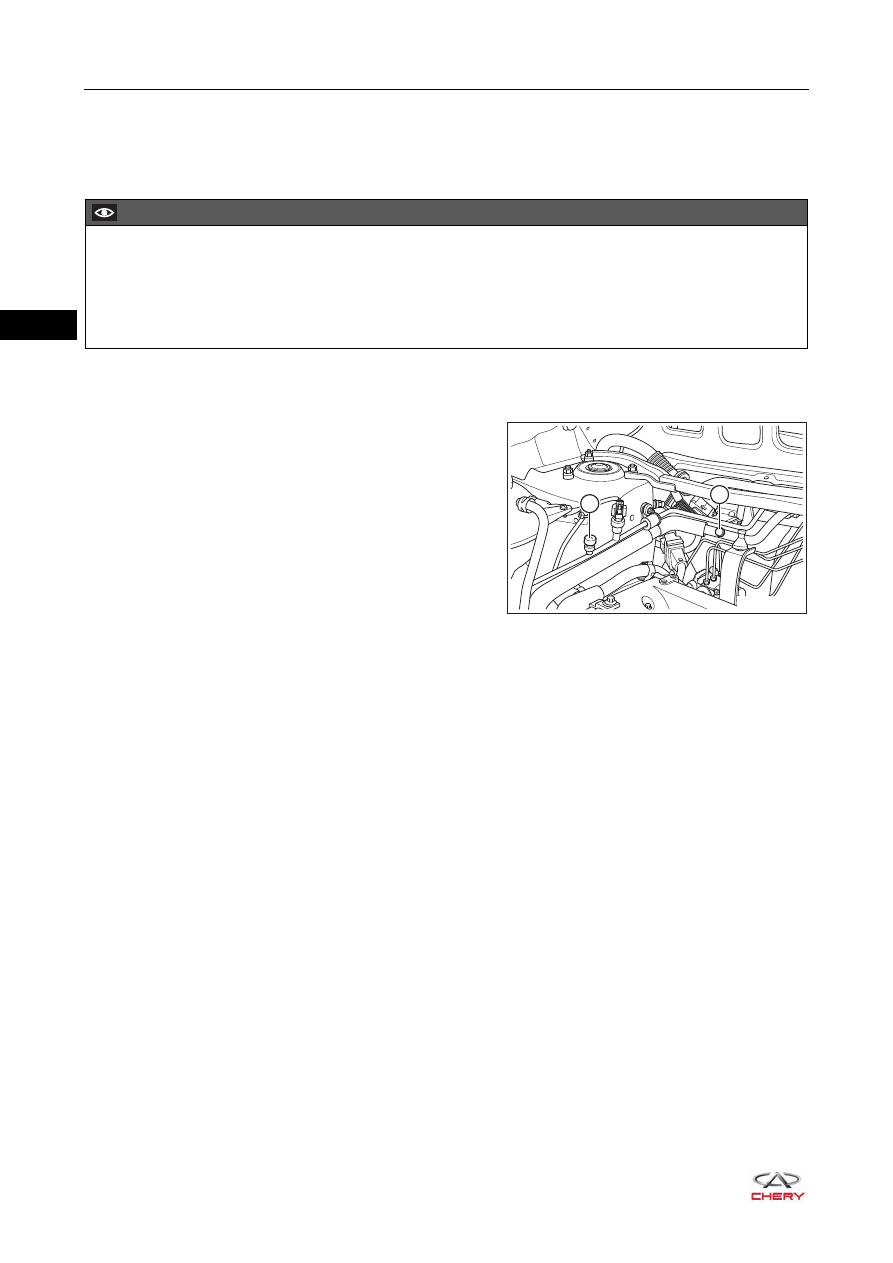

1. Open the engine hood and loosen the joint cover of A/C high/low pressure line.

2. Connect the refrigerant recycling machine to A/C high/low pressure line joint.

a. Connect the red connector to A/C high pressure line

joint (1).

b. Connect the blue connector to A/C low pressure line

joint (2).

3. Open the high pressure valve and low pressure valve of refrigerant recycling machine.

4. Recover the refrigerant oil according to the instructions on machine.

5. Record the amount of recovered refrigerant oil.

6. Disconnect the connections between refrigerant recycling machine and A/C line joint.

7. Reinstall the joint cover onto the refrigerant line joint.

CAUTION

Special service equipment for R134a refrigerant must be used.

Always keep the work area in good ventilation, because the A/C system is easy to leak.

Always dispose of the recovered refrigerant as specified.

Refrigerant oil must be charged after replacing the A/C system components or recovering the refrigerant.

RT21310050

1

2