Chery Tiggo 5 (T21). Manual - part 68

06–

114

06

a. Remove knock sensor.

b. Check installation area of knock sensor, and check for damage, foreign matter and excessive movement,

etc. that cause signal incorrectness.

a. Check resistance between knock sensor terminals 1 and 2.

OK: 4.9 ± 20% MΩ (at normal temperature)

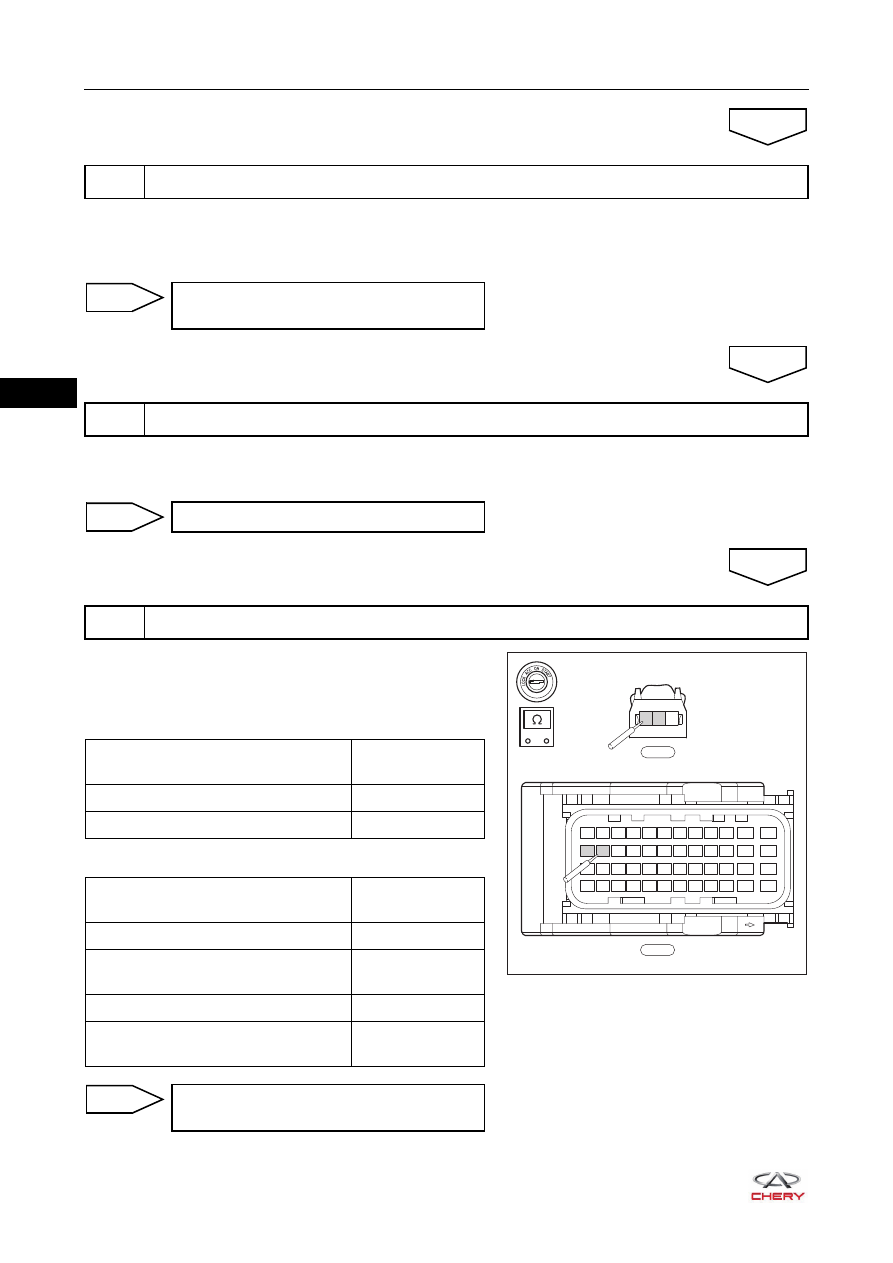

a. Disconnect ECM wire harness connector E-035.

b. Check wire harness between terminals of connector E-035

and connector E-005.

Check for Open

Check for Short

3

Check installation of knock sensor

OK

Clean installation area or replace knock

sensor

NG

4

Check resistance of knock sensor

OK

Replace knock sensor

NG

5

Check knock sensor signal circuit

OK

E-035

E-005

37 38 39 40 41 42 43 44 45 46

47

48

25 26 27 28 29 30 31 32 33 34

35

36

13 14 15 16 17 18 19 20 21 22

23

24

1

2

3

4

5

6

7

8

9 10

11

12

1 2 3

-

+

RT21065043

Multimeter Connection

Specified

Condition

E-035 (26) - E-005 (1)

Continuity

E-035 (25) - E-005 (2)

Continuity

Multimeter Connection

Specified

Condition

E-035 (26) or E-005 (1) - Body ground

No continuity

E-035 (26) or E-005 (1) - Battery

positive

No continuity

E-035 (25) or E-005 (2) - Body ground

No continuity

E-035 (25) or E-005 (2) - Battery

positive

No continuity

Replace wire harness or connector (knock

sensor - ECM)

NG