Lotus Elise / Lotus Exige. Manual - part 53

Lotus Service Notes Section HG

Page 8

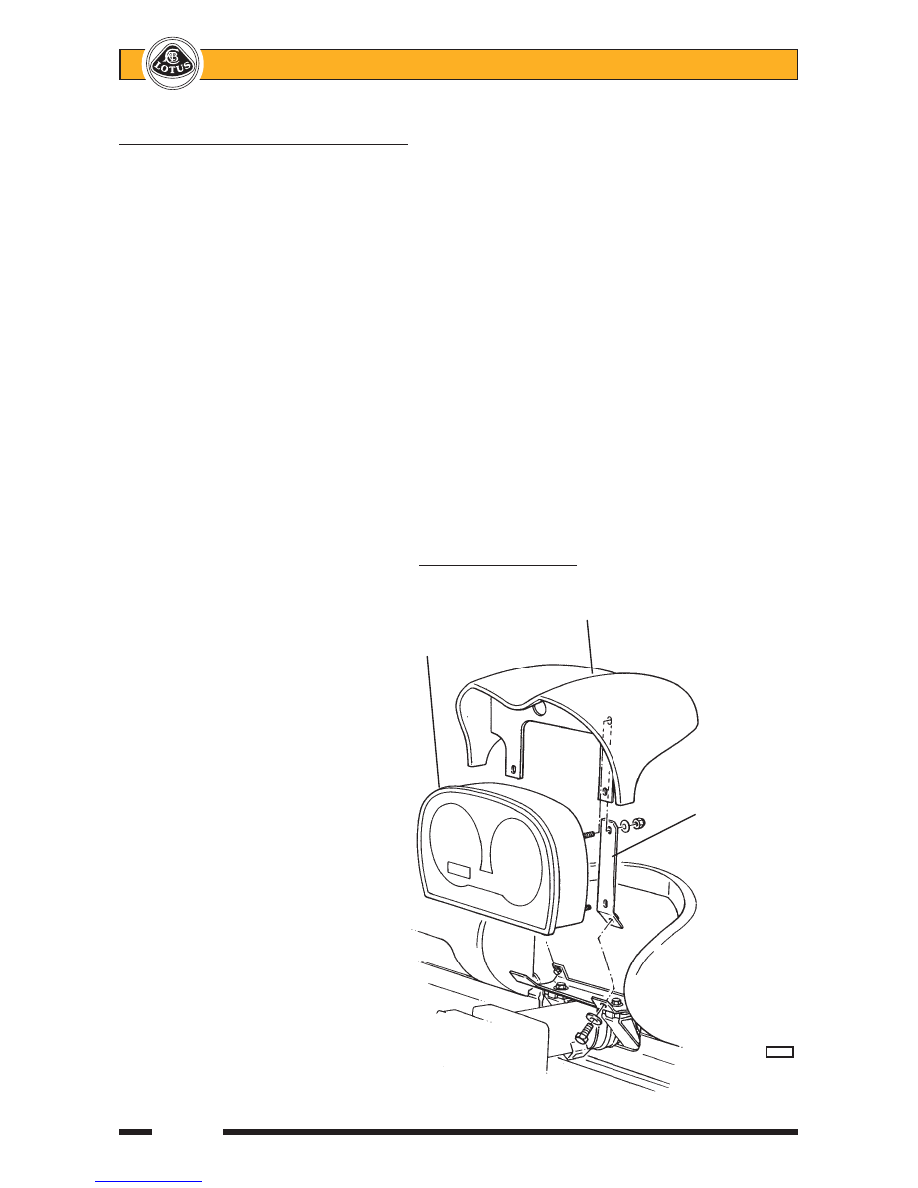

To Remove Upper Steering Column Assembly

WARNING: On cars so equipped, the driver's airbag is housed in the hub of the steering wheel.

Precautions need to be taken for personal safety when working with airbags and associated

componentry. Do not attempt to remove the airbag, steering wheel or column without first referring to

section WD.

1.

Disconnect the battery, and remove the column shrouds (see sub-section HG.2).

2.

Disconnect the column lever switches, or release the retaining pawls and slide the switches out of the

carrier. Disconnect the horn contact pin. On airbag equipped cars, refer to section WD and unplug the

yellow airbag harness connector.

3.

To disconnect the ignition switch: prise open the terminal cover, and use a small screwdriver to release

the retaining barb located between the white and yellow cables. Withdraw the connector.

4.

If necessary, remove the steering lock/ignition key barrel: Turn the key to position 'I', depress the spring

pin accessible via a hole in the column switch carrier, and withdraw the lock barrel.

5.

If necessary, remove the ignition switch: First remove the steering lock/ignition key barrel (see above).

Remove the retaining grub screw and withdraw the switch.

6.

If necessary, remove the steering lock assembly: Remove the spline head screw securing the column

switch carrier, and drill or chisel out the two shear head bolts fixing the lock assembly to the column.

7.

Remove the pinch bolt securing

the upper universal joint to the in-

termediate column.

8.

On non-airbag cars, remove the

two fixings for the instrument pack

mounting brackets, and remove

the instrument pack and cowl as-

sembly after unplugging the sin-

gle harness connector.

On airbag equipped cars, with-

draw the instrument surround and

cowl straight rearwards from the

dash panel to release the spring

clips. Remove four screws to re-

lease the instrument pack mount-

ing bracket from the dash and

unplug the two harness connec-

tors

9.

Release the two bolts securing the

upper column clamp to the dash

brackets, and remove the switch

pack.

10.

From the access provided by the

removal of the switch pack, re-

lease the upper column single

lower fixing and withdraw the col-

umn assembly from the scuttle

and off the intermediate steering

column.

Non-airbag type shown

Instrument cowl

Instrument

pack

Instrument

& cowl

mounting

bracket

b259a