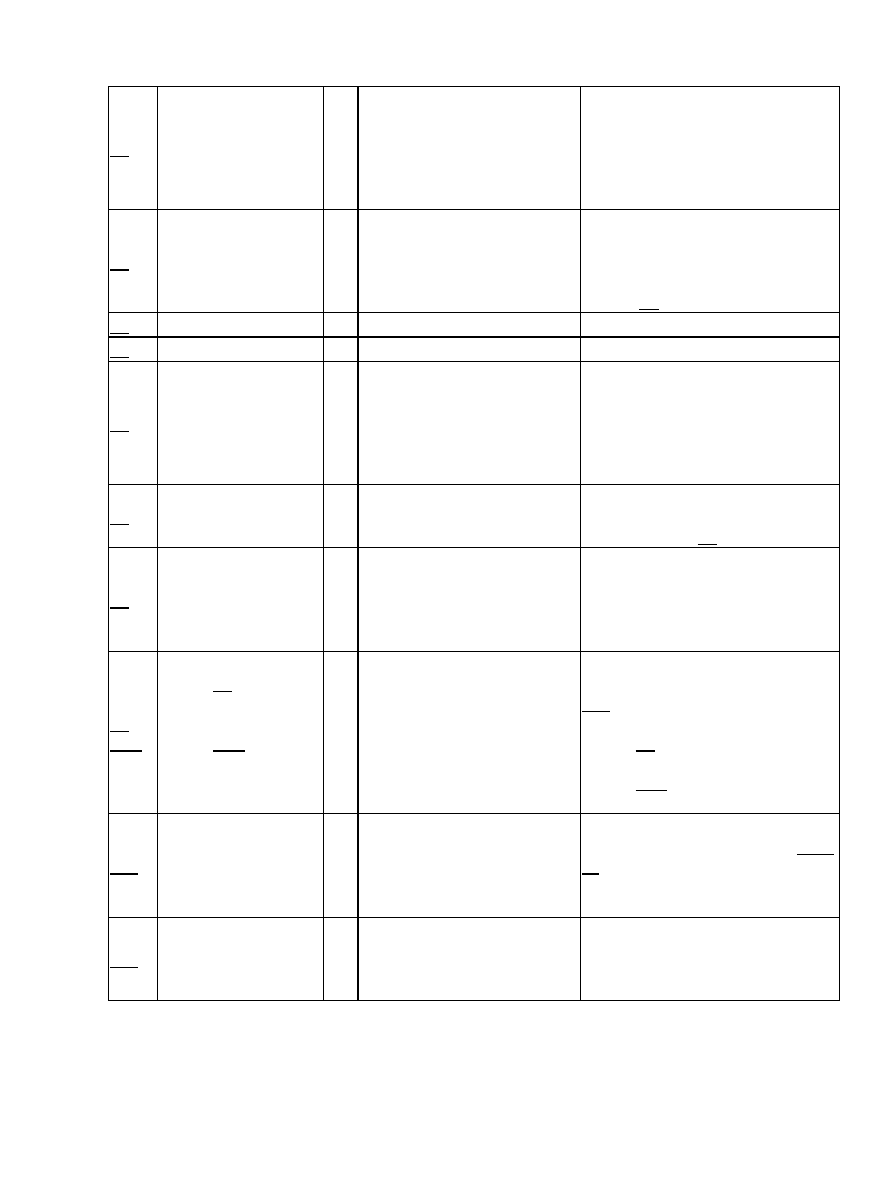

Porshe 911 (997). Manual - part 260

Spring strut mount

1

Observe allocation as per Spare Parts

Catalogue.

During fitting, place the lug in the

groove on the piston rod (twist lock of

piston rod opposite the supporting

mount).

Compensating plate

(intermediate part)

1

Observe allocation, depending on coil

spring tolerance range (see assembly

instructions).

Join to spring plate at the correct

position -4- .

Spring plate

1

Replace if necessary.

Washer

1

1

Observe allocation as per Spare Parts

Catalogue.

PASM and sport-type running gear:

approx. 53 mm long.

Standard running gear: approx. 67

mm long.

Bellows

1

Replace if necessary. Before

installation, assemble with the

additional spring -6- .

Coil spring

1

Observe allocation as per Spare Parts

Catalogue.

Always replace both coil springs at

the same time (coil springs are only

available in pairs).

or

Concave washer

Variant -9- = 78 mm

diameter

or

Variant -9.1- = 134 mm

diameter (consisting of

concave washer and

rubber support)

1

Fit groove downwards facing snap

ring. Ensure perfect fit on snap ring

-10-

Observe allocation.

Variant -9- for standard running gear

and PASM chassis.

Variant -9.1- for sport-type running

gear (Performance).

Snap ring

1

Use snap-ring pliers VW 161a

for removal and installation.

Replace. Fit in the specified groove

using snap-ring pliers VW 161a -A or

B-

(observe table during assembly).

Make sure it fits perfectly in the

groove!

Vibration damper

1

Observe allocation as per Spare Parts

Catalogue.

The item number is shown on the

damper tube.

Diagnostic system: reading out fault memory and activating systems

Component and assembly overview (with and without PASM)

1197