Porshe 911 (997). Manual - part 172

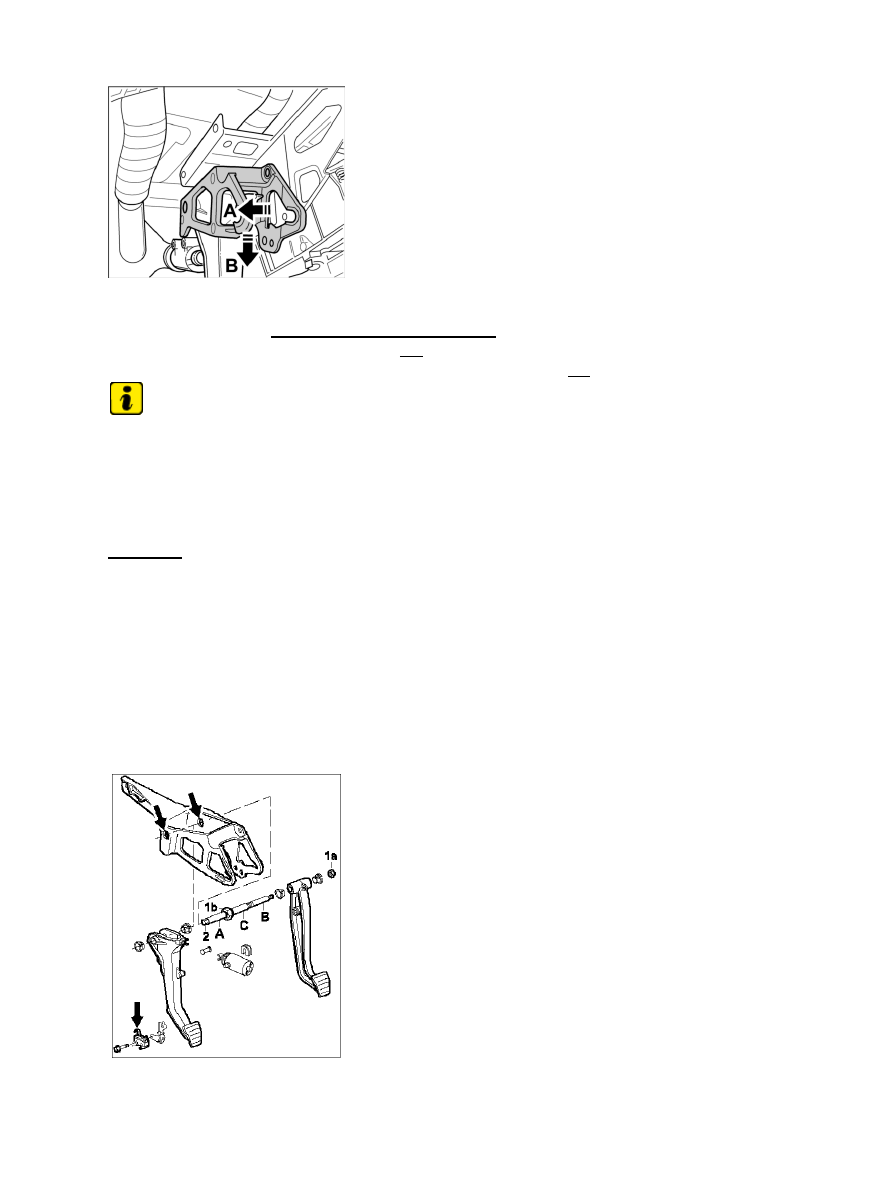

Bracket for clutch power spring

6. Loosen bracket for clutch power spring (support for clutch pedal switch and remove interlock

switch, if necessary) → Bracket for clutch power spring . Carefully move bracket for clutch power

spring approximately 2-4 mm to the left -A- . Carefully turn bracket for clutch power spring

clockwise on the pedal bearing axle approximately 10-15 degrees -B- .

Note

When removing the bracket for the clutch power spring, carefully guide the master cylinder valve pushrod

past at the clutch pedal.

7. Pull out bracket for clutch power spring to the left and take out the clutch

pedal.

Installing

Diagnostic system: reading out fault memory and activating systems

Removing

845