Snowmobile Arctic Cat (2008 year). Manual - part 137

7-108

FZ084A

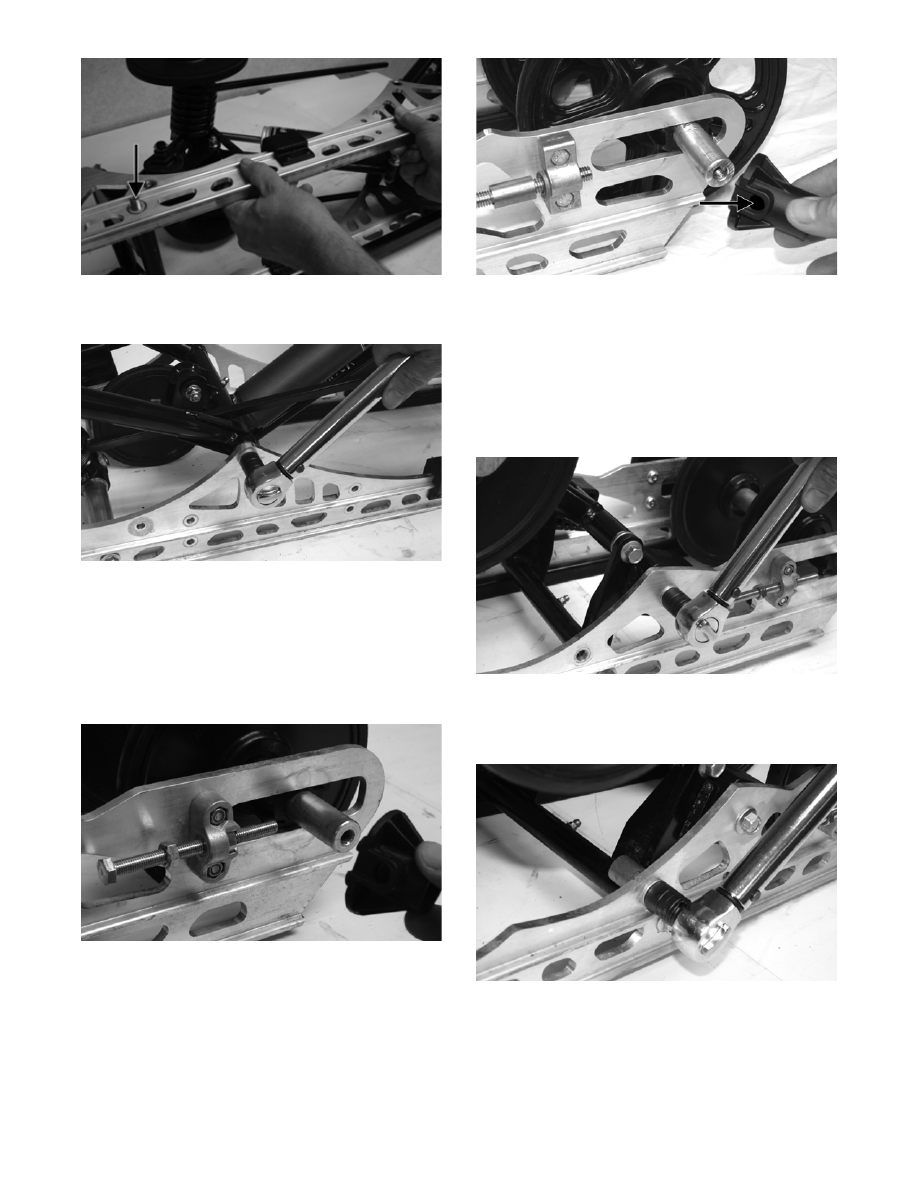

5. Secure the front arm to the slide rail with the cap

screws and lock nuts. Tighten to 32 ft-lb.

FZ070

NOTE: At this point, return to steps 3 and 4 and

tighten the rear arm and front arm cap screws and

lock nuts to 40 ft-lb.

6. Install the adjuster bushing and rear idler wheel.

Install a cap screw and flat washer. Tighten only

until snug.

FZ066

NOTE: Care must be taken that the adjuster

bushing slot with the hole is aligned properly with

the adjuster bolt.

CM261A

NOTE: It is advisable to tighten the rear idler

wheel axle only until snug until the skid frame has

been installed and track tension has been

adjusted; then the axle assembly must be tight-

ened to 20 ft-lb.

7. Install coupler block w/bushing. Secure with cap

screw. Tighten securely.

FZ076

8. Install the rear arm limiter and secure with the cap

screw. Tighten the cap screw (coated with blue

Loctite #243) to 50 ft-lb.

FZ075

9. Place the spring into the slide block; then place the

spring slide and slide block assembly into position

on the slide rail. Secure with a cap screw and

washer. Tighten to 20 ft-lb.