Snowmobile Arctic Cat (2008 year). Manual - part 135

7-100

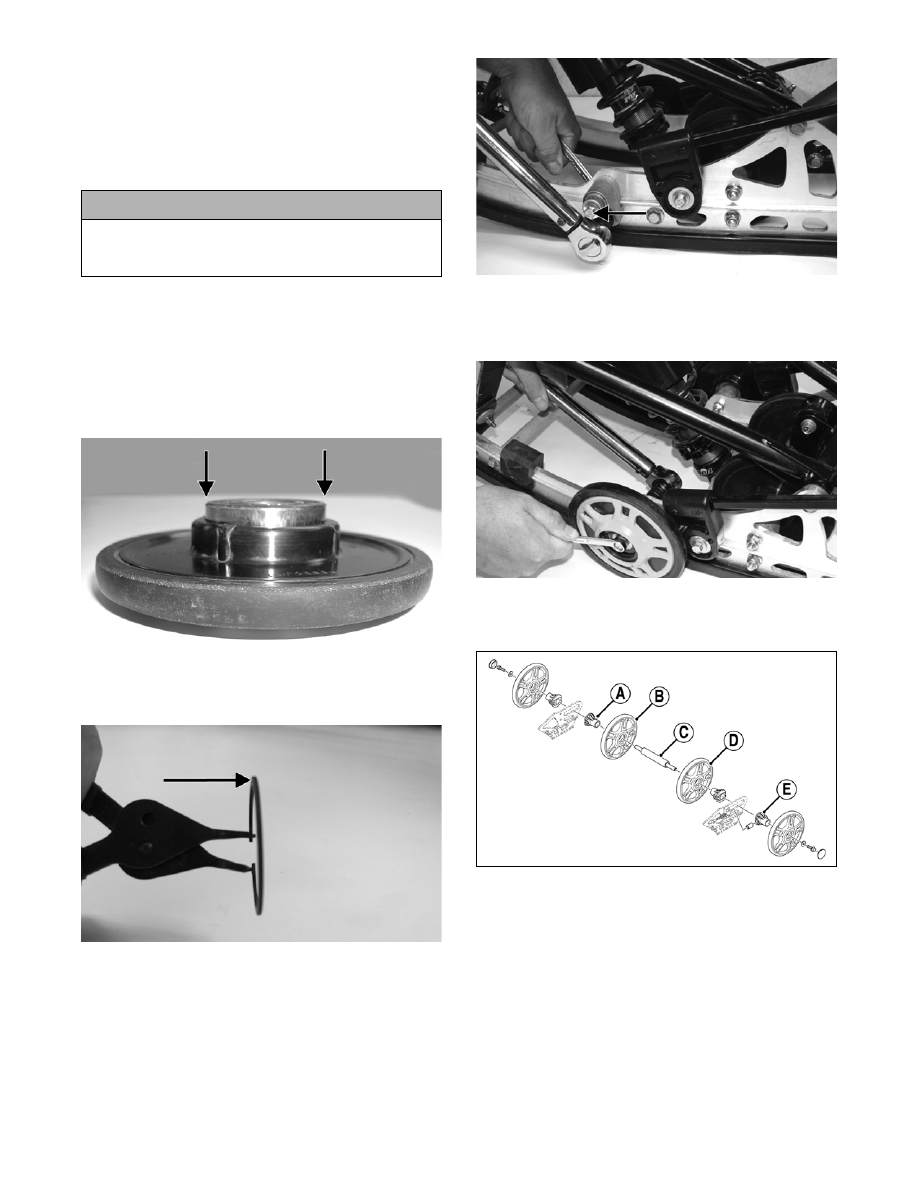

1. Clean the bearing with a clean cloth.

2. Inspect each idler wheel for cracks or damage.

3. Rotate the idler wheel bearing (by hand) and

inspect for binding or roughness.

4. If a bearing must be replaced, use this procedure.

A. Remove the bearing snap ring.

B. Using a suitable press or suitable driving tool,

remove the bearing from the inside of the

wheel.

C. Press the new bearing (on its outer race) into

the idler wheel.

MS006A

D. Install the snap ring making sure the “sharp

side” is directed away from the bearing.

MS007A

INSTALLING SLIDE RAIL IDLER

WHEELS

1. Secure the mounting block on the slide rail with a

cap screw and lock nut. Tighten to 20 ft-lb.

NOTE: For proper alignment, it is advisable to

install an idler wheel cap screw into the top mount-

ing block hole prior to tightening.

FZ031A

2. Place the idler wheel to the mounting block; then

secure the idler wheel assembly with a cap screw,

flat washer, and a lock nut. Tighten to 20 ft-lb.

FZ032

ASSEMBLING REAR AXLE

742-873A

1. In order from the right-hand side, slide the axle

through the slide rail axle slot; then place a bush-

ing (A), inner idler wheel (B), rear idler wheel

spacer (C), inner idler wheel (D), and bushing (E)

on the axle. Slide the axle through the opposite

slide rail axle slot.

2. Place the plastic adjuster bushings on the axle (on

the outside of each axle slot); then install the outer

idler wheels on the axle and secure with two cap

screws (coated with blue Loctite #243) and large

flat washers. Tighten cap screws only until snug.

! CAUTION

Do not remove the bearing unless it is absolutely

necessary. The bearing will be damaged during

removal.