Snowmobile Arctic Cat (2008 year). Manual - part 133

7-92

CLEANING AND INSPECTING

NOTE: Whenever a part is worn excessively,

cracked, or damaged in any way, replacement is

necessary.

1. Clean the slide rail using parts-cleaning solvent

and compressed air.

2. Inspect the slide rail for cracks. If any cracks are

found, replace the slide rail.

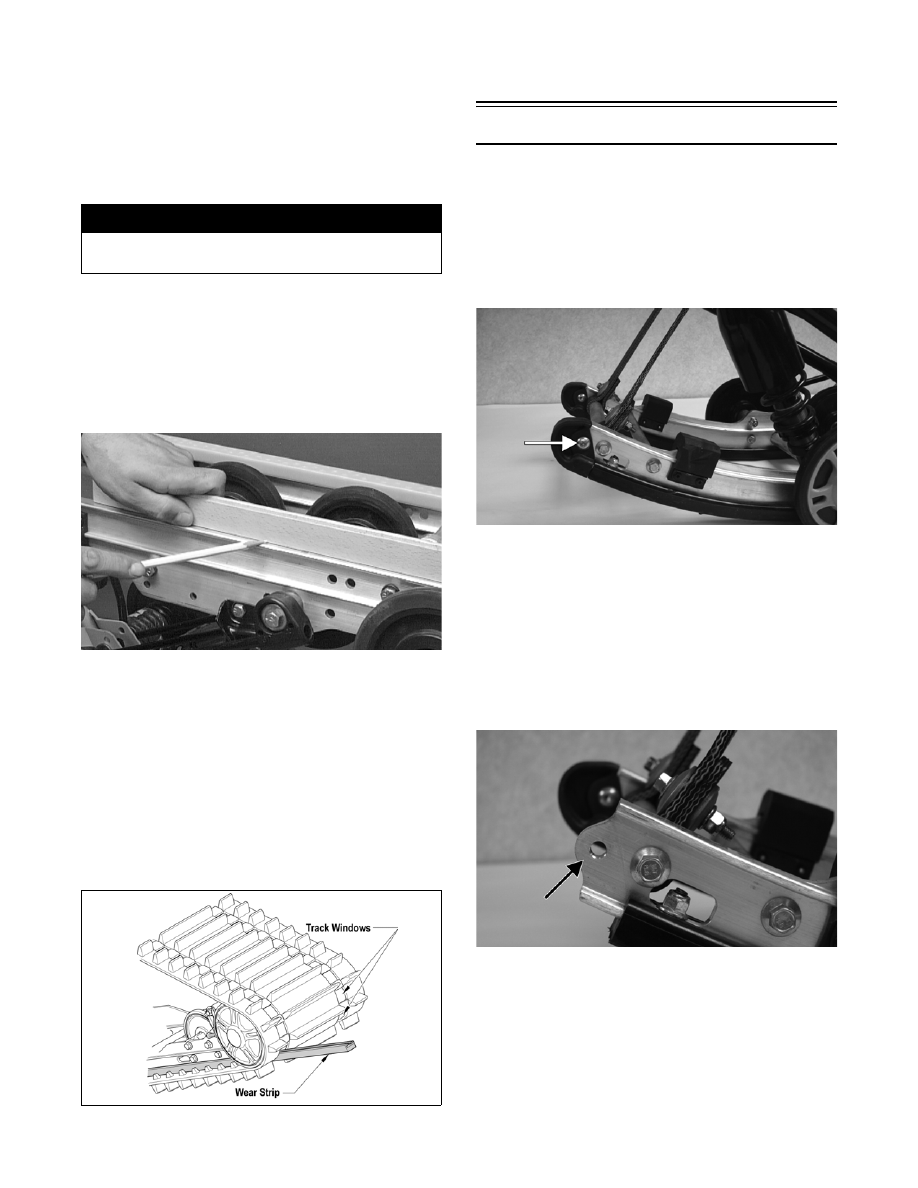

3. Using a straightedge, inspect the slide rail for any

unusual bends. With the slide rail removed, place

the straightedge along the bottom surface of the

slide rail. If the rail is found to be bent, it must be

replaced.

AG536D

INSTALLING

NOTE: Apply a light coat of grease to the slide

rail surface to aid in installing a new wear strip. If

there are any sharp edges on the lower portion of

the rail, use a file to remove them.

1. Align the wear strip with the openings (windows)

in the track and from the back, start the wear strip

onto the rail; then using a block of wood and a ham-

mer, drive the wear strip forward into position.

739-884A

2. Secure with a machine screw and lock nut. Tighten

to 50 in.-lb.

End Caps

NOTE: The skid frame does not have to be

removed for this procedure.

REMOVING

1. Remove the lock nut and cap screw securing the

end cap.

FZ026A

2. Using a hammer, tap the end cap off the rail.

CLEANING AND INSPECTING

NOTE: Whenever a part is worn excessively,

cracked, or damaged in any way, replacement is

necessary.

1. Inspect the end cap area of the slide rail for cracks

and wear.

FZ027A

2. Inspect the end cap for any signs of cracking or

wear.

! WARNING

Always wear an approved pair of safety glasses

when using compressed air.