Snowmobile Arctic Cat (2008 year). Manual - part 117

7-28

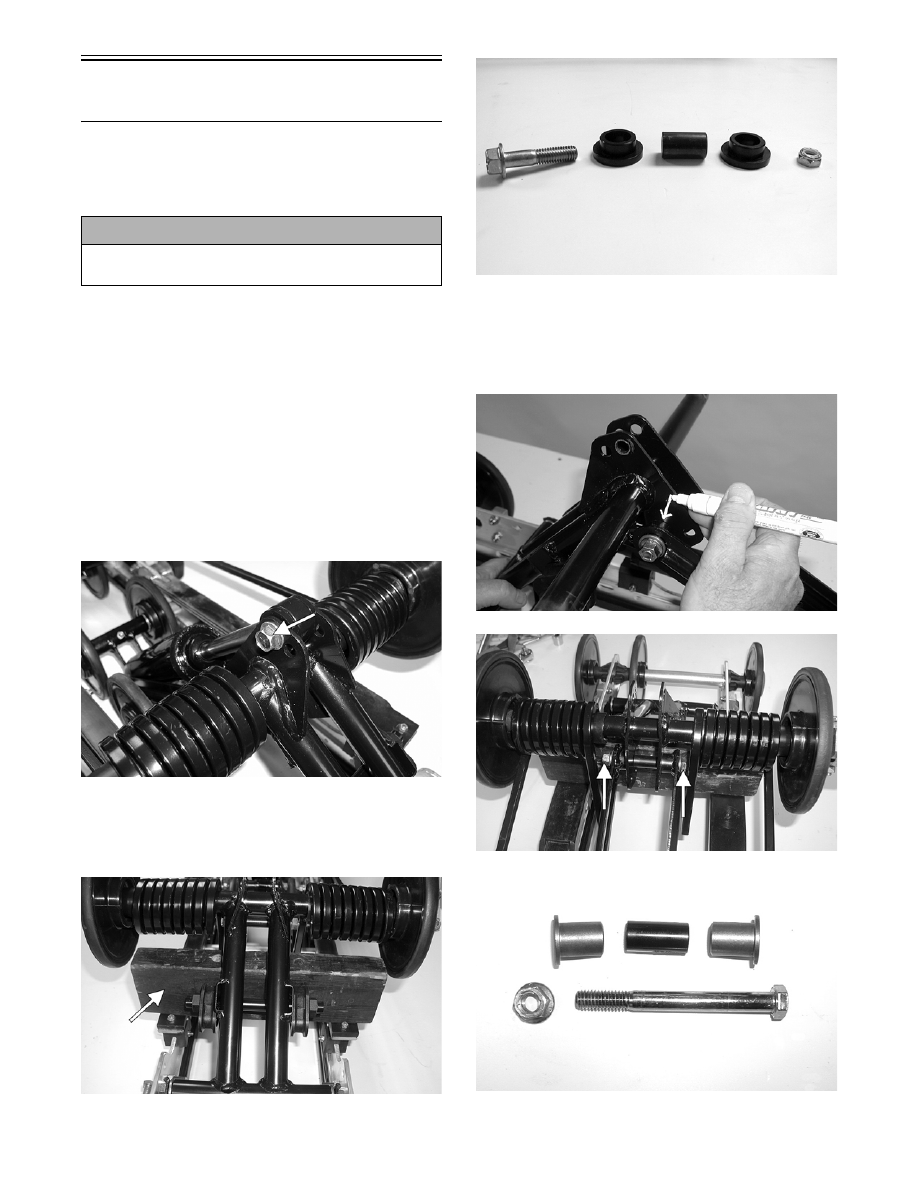

Rear Shock Absorber

and Shock Links

NOTE: Before removing the skid frame by using

the Rear Suspension Spring Tool, remove the

spring from the adjusting cam.

NOTE: The skid frame must be removed for this

procedure (see Removing Skid Frame in this sub-

section).

DISASSEMBLING

NOTE: When removing center components from

the skid frame, it is advisable to loosen all cap

screws/lock nuts from one side of the slide rail to

make removing easier.

1. Disengage the shock absorber at the upper eyelet

and remove the shock absorber. Account for a

sleeve, cap screw, lock nut, and bushings.

MS089A

NOTE: For ease of disassembling, it is advis-

able at this point to place a block of wood between

the idler arm and the overload springs.

MS090A

MS091

2. Mark the hole that the upper shock links are

mounted in for assembly purposes; then remove

the cap screw and lock nut securing the shock

links to the upper arm bracket. Account for all

mounting hardware.

MS076

MS092A

MS093

! CAUTION

Care must be taken when removing the spring from

the adjusting cam or damage or injury could result.