Snowmobile Arctic Cat (2008 year). Manual - part 79

4-32

NOTE: Before starting the engine, make sure

that no air is present in the testing equipment.

8. With the control arm secured in the FULL-OPEN

position (line-to-line), run the engine at recom-

mended RPM for 2 minutes. Compare the amount

of oil used against the specifications on the chart

in Section 1.

9. If the oil-injection pump output does not meet the

specifications, see Testing Oil-Injection Check

Valves in this sub-section.

10. Disconnect the oil usage tool, remove the plug

from the reservoir, attach the oil-supply hose to the

oil reservoir, and remove the vacuum pump.

NOTE: After testing the oil pump, it is critical

that the oil pump is correctly synchronized with

the carburetor(s)/throttle bodies (see Synchroniz-

ing Oil-Injection Pump on page 30 in this section).

Testing Oil-Injection

Check Valves

In the event there is an engine problem due to lack of

lubrication, the oil-injection pump check valves should

be tested using a vacuum pump to make sure the check

valves are operating properly.

When testing the check valves, remove them from the

pump assembly.

1. Remove the check valves from the oil-injection

pump.

731-551A

2. Attach the vacuum test pump hose to the check

valve.

3. Squeeze the vacuum pump handle and watch the

pump gauge. The check valve should release at

4.5-5 lb and again reset itself at 3.5-4 lb. If

“release” and “reset” are not within specifications,

replace the check valve.

4. Record the “release” and “reset” readings for the

valve; then perform the test on the other valve.

The “release” and “reset” readings must fall within

specifications and must be within 1.5 lb of each

other. If either or both are not met, replace the

check valves.

5. If the check valves are within specifications but

the oil-injection usage is not, replace the oil-injec-

tion pump.

Fuel Pump

(Carbureted Models)

PRELIMINARY CHECKS

1. Make sure the gas tank shut-off valve is in the

OPEN position.

2. Make sure there is adequate gasoline in the gas

tank.

3. Make sure all hoses are clear and free of kinks and

obstructions.

4. Make sure the fuel filter is not plugged or dam-

aged.

5. Make sure fuel and impulse hoses are in good con-

dition.

6. Make sure there is evidence of good impulse at the

crankcase impulse fitting.

TESTING PRESSURE

1. Connect a pressure gauge between fuel pump and

carburetor using a piece of fuel hose and a T-fit-

ting.

2. Place snowmobile on a safety stand and start the

engine. At the following engine speeds, the speci-

fied pressures must be indicated.

3. Remove gauge and hose and connect fuel hose to

carburetor.

! CAUTION

Whenever servicing the oil-injection system, use a

100:1 gas/oil mixture in the gas tank to ensure ade-

quate engine lubrication. Failure to use the 100:1

mixture to the oil-injection system will result in

severe engine damage.

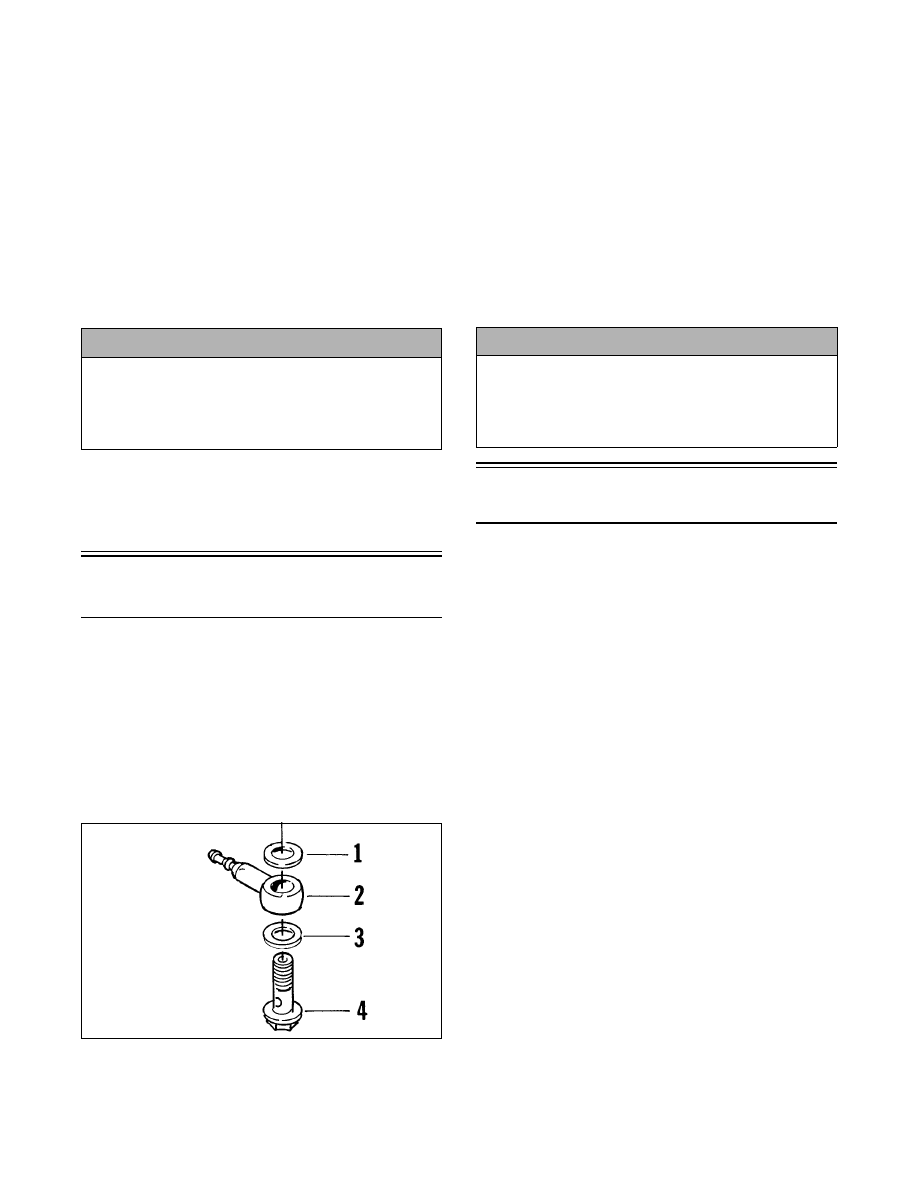

KEY

1. Gasket

2. Check Valve

3. Gasket

4. Union

! CAUTION

Whenever servicing the oil-injection system, use a

100:1 gas/oil mixture in the gas tank to ensure ade-

quate engine lubrication. Failure to use the 100:1

mixture to the oil-injection system will result in

severe engine damage.