Snowmobile Arctic Cat (2008 year). Manual - part 77

4-24

EFI Analyzer/

Diagnostic Tool

NOTE: For testing the 800/1000 cc EFI system,

refer to the EFI Diagnostic System Manual, which

accompanies Laptop Diagnostic Tool and Laptop

Diagnostic Test Kit.

NOTE: To aid in testing the 500/600 cc EFI sys-

tem, refer to the EFI Analyzer Usage Manual, which

accompanies EFI Analyzer Kit.

Throttle Body

Assembly

741-871A

0740-804

0741-330

REMOVING

NOTE: The expansion chamber and air silencer

must be removed for this procedure (see Section

2).

1. Disconnect the wiring harness from each injector

and from the throttle position sensor connector.

2. Remove the coolant hoses from the throttle body

assembly and plug them to prevent leakage.

3. Remove the fuel supply hose from the fuel rail.

4. Loosen the flange clamps.

5. Slide the throttle body assembly out of the flanges;

then loosen the jam nut securing the throttle cable

and remove.

6. Where applicable, remove the oil pump control

rod.

7. Remove the throttle body assembly.

INSTALLING

1. Attach the throttle cable to the throttle body.

Secure with jam nut.

2. Place the throttle body assembly into position.

Make sure the flanges and boots are positioned

properly. Secure with flange clamps.

3. Where applicable, connect the oil pump control

rod.

KEY

1. Throttle Body

2. Throttle Position

Sensor

3. Screw

4. O-Ring

5. Fuel Rail

6. Bolt

7. Fuel Injector

8. Cushion

500 cc

600 cc

KEY

1. Throttle

Body

2. Fuel Rail

3. Fuel Injector

4. Screw

5. Hose

6. Clamp

7. O-Ring Set

8. Throttle Position Sensor

9. Screw

10. Control Rod

! CAUTION

Since the fuel supply hose may be under pressure,

remove it slowly to release the pressure. Place an

absorbent towel around the connection to absorb

fuel.

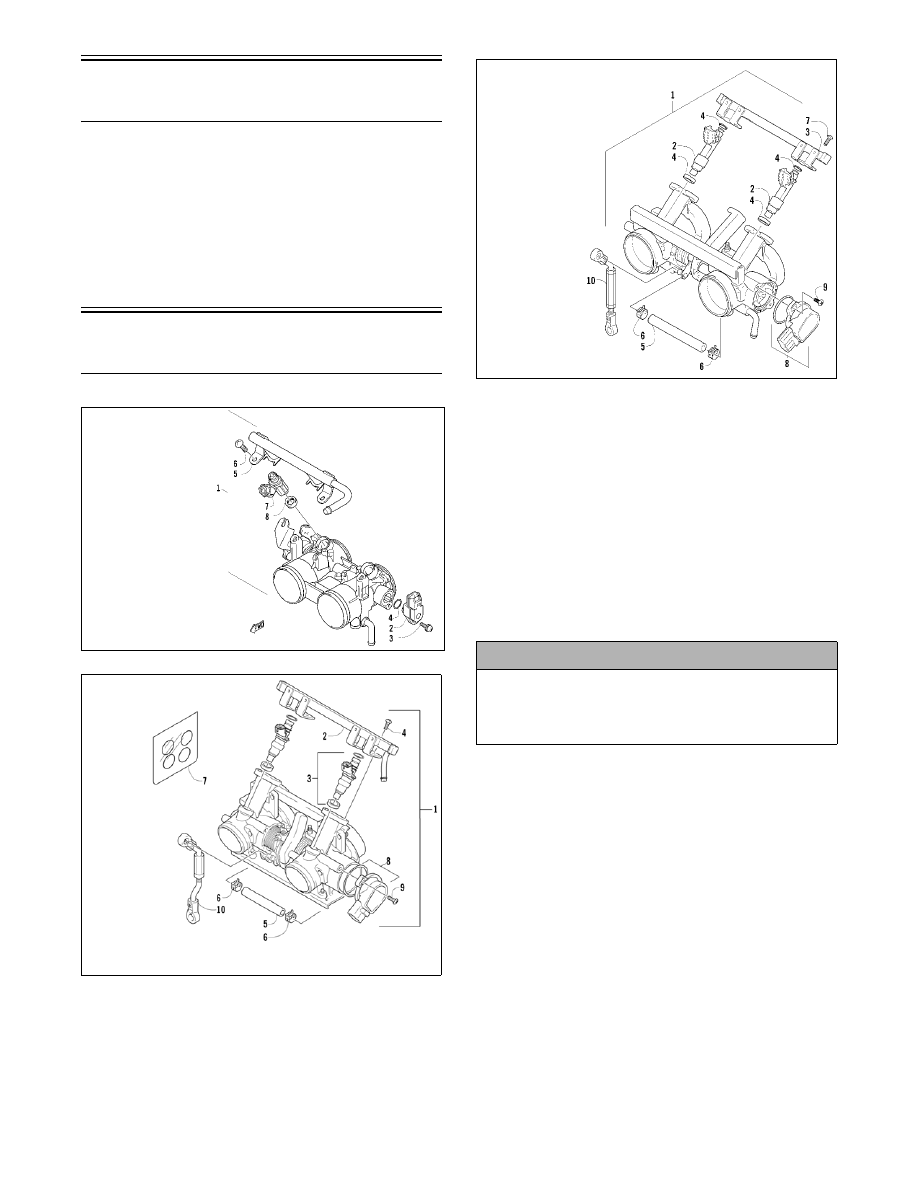

KEY

1. Throttle Body

2. Fuel Injector

3. Fuel Rail

4. O-Ring

5. Hose

6. Clip

7. Screw

8. Throttle Position

Sensor

9. Screw

10. Control Rod

800/1000 cc