Snowmobile Arctic Cat (2008 year). Manual - part 70

3-24

Check for correct exhaust valve cable length specifica-

tions for model being worked on in this section.

Servomotor Makes No Attempt To

Cycle

If when running the engine the servomotor makes no

attempt to operate, this is caused by one or more of the

following:

A. Bad connection from the wiring harness and

connector from the lighting coil to the CCU, to

the ECU, or from the ECU to servomotor.

B. CCU output (gauge/taillight/APV) is shorted or

open.

C. ECU output to servomotor is too low.

D. Servomotor failure.

NOTE: For testing individual APV system compo-

nents, see Section 5.

MAINTENANCE

The APV system requires only periodic cleaning and

cable adjustment. The cables should be checked every

1000-2000 miles and adjusted as necessary. To ensure

maximum performance and minimize maintenance

requirements, Arctic Cat recommends using Arctic Cat

Synthetic APV 2-Cycle Oil. Using oils other than the

recommended oil may increase the frequency of

required cleaning due to increased buildup of carbon

deposits.

CABLE ADJUSTMENT

Proper cable adjustment is critical to the operation of

the APV system. While it is recommended that the

cable adjustment be inspected every 1000-2000 miles,

the cable should not need adjustment often. To check

the cable adjustment, use the following procedure.

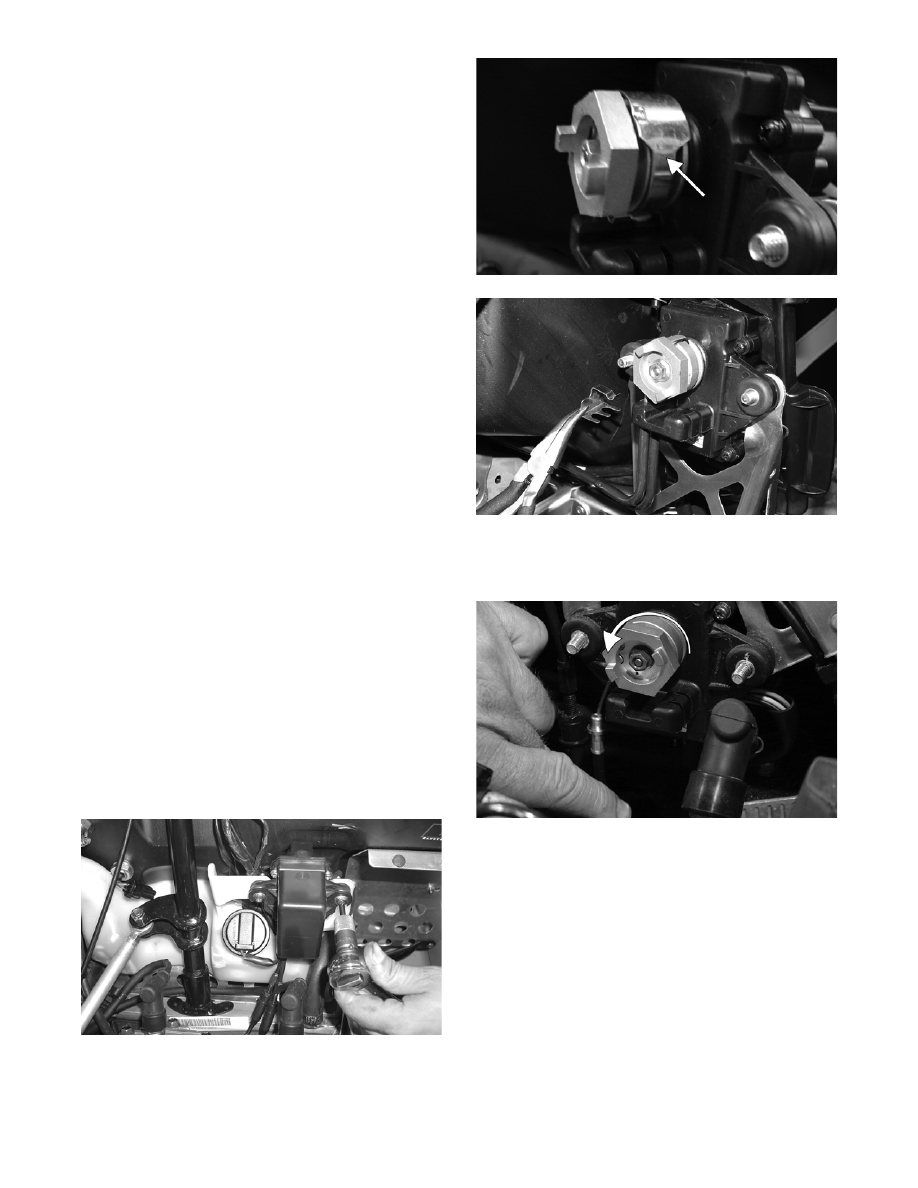

1. On the Crossfire/M-Series, remove the two cap

screws securing the servomotor cover.

FC004

2. Using a small needle-nose pliers, remove the ser-

vomotor retaining clip (800/1000 cc) and the cable

holder.

FS273A

CM127

3. Rotate the servomotor actuator counterclockwise

to loosen the cable; then pull the cable housings

down and out of the servomotor.

CM123A

NOTE: For installing purposes, note the side that

the servomotor cables are installed on.

4. Slide each cable drum out of the slot of the servo-

motor actuator.