Snowmobile Arctic Cat (2008 year). Manual - part 42

2-105

2

CM191A

NOTE: On the 1000 cc, remove the coolant

bypass hoses from the cylinders.

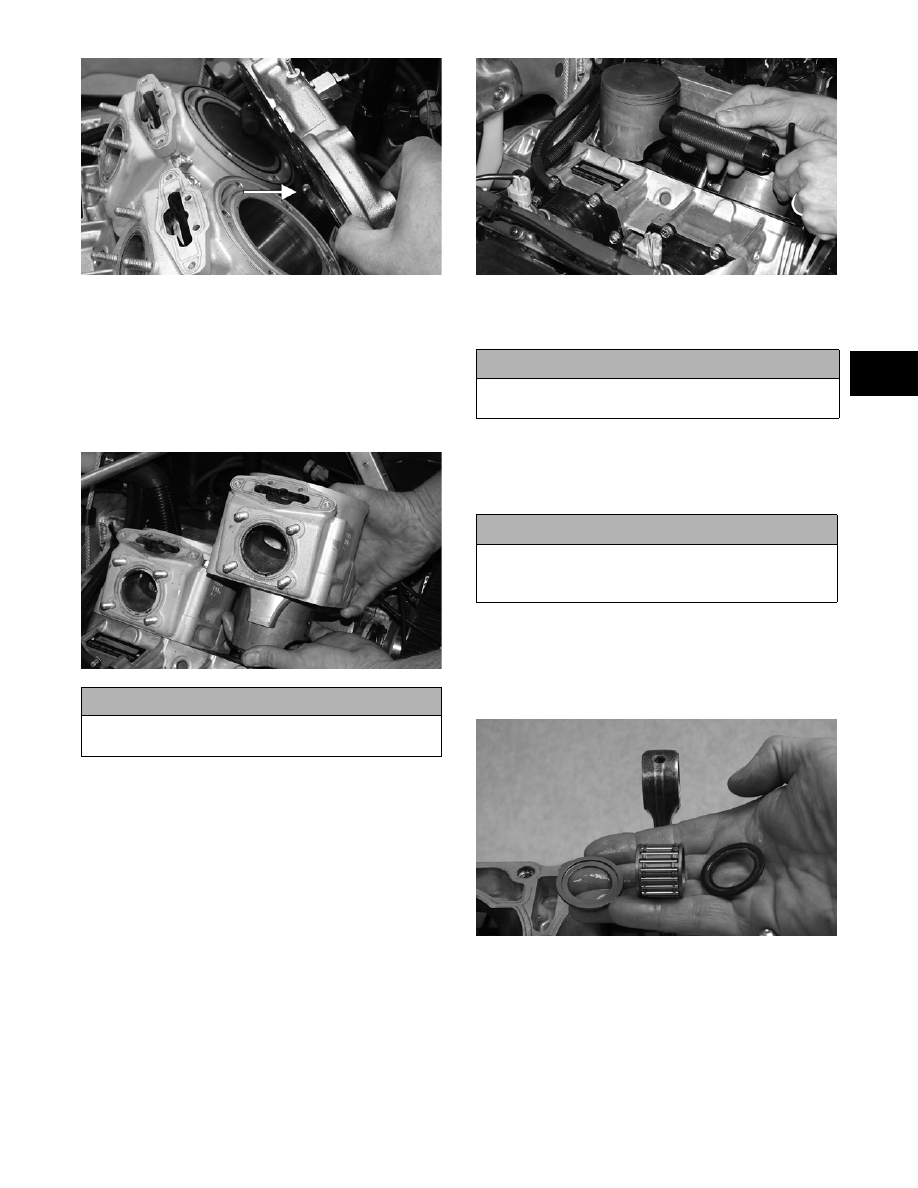

8. Remove the cap screws and nuts securing the cyl-

inders to the crankcase; then using a soft hammer,

gently tap the cylinders and remove from the

crankcase by lifting them straight up off their

studs. Account for gasket(s) and alignment pins.

CM192

NOTE: If servicing the MAG-side only, the PTO-

side cylinder must be removed.

NOTE: After the cylinders have been removed, it

is advisable to cover the crankcase to avoid com-

ponents falling into the crankcase.

9. Remove the PTO-side piston-pin circlip from the

PTO-side piston; then remove the PTO-side pis-

ton-pin circlip from the MAG-side piston.

10. Using Piston Pin Puller and Medium Extractor

Nut, remove the piston pins from both pistons.

CM193

NOTE: The piston pins must be removed from the

PTO-side of the piston.

NOTE: For proper assembly, keep all MAG-side

components and all PTO-side components sepa-

rated. Assemble them on their proper sides.

11. Lift the pistons clear of the connecting rods and

remove the small-end connecting-rod bearings

(account for two washers); then remove the piston

rings. Keep each piston with its rings; keep each

piston pin and bearing together as a set.

CM151

NOTE: Place a suitable length of rubber hose

around the connecting rods. This will prevent the

connecting rods from damaging the crankcase.

NOTE: For servicing procedures, see Cleaning

and Inspecting Engine and Measuring Critical

Components in this sub-section.

! CAUTION

When removing a cylinder, be sure to support the pis-

ton to prevent damage to the crankcase and piston.

! CAUTION

Do not use the large extractor nut to remove the pin

or damage to the piston may occur.

! CAUTION

DO NOT use any type of punch to drive the piston

pin free of the piston; damage may result. Use a pis-

ton-pin puller only.