Snowmobile Arctic Cat (2008 year). Manual - part 40

2-97

2

CM137

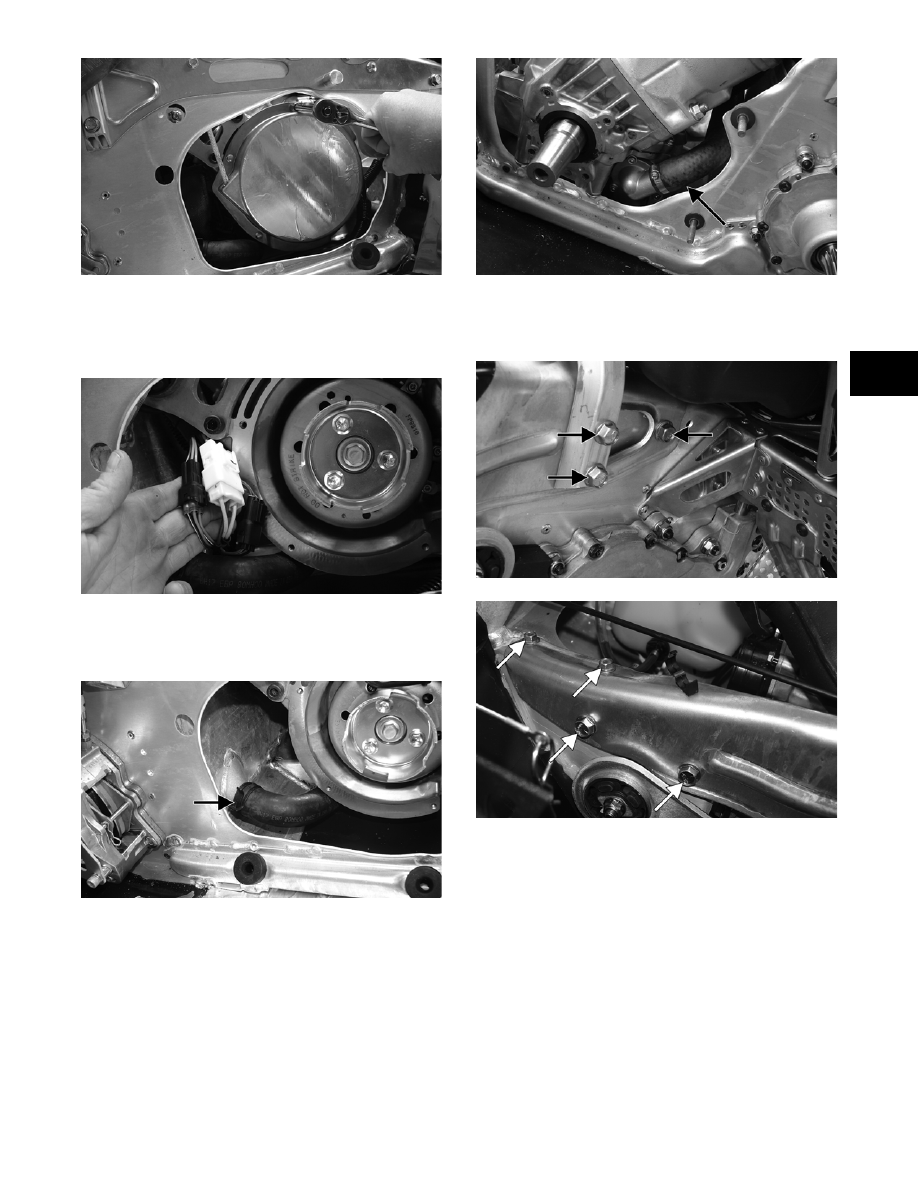

18. Remove the wiring harness wrap; then disconnect

the ignition/main harness connectors and the tem-

perature sensor connector. Secure the harness out

of the way.

CM134

19. Disconnect the lower coolant hose from the front

heat exchanger; then remove the remaining cool-

ant hose from the thermostat outlet.

CM135A

CM136A

20. Remove the cap screws and lock nuts securing the

steering support and the side-plate brace to the

chassis.

CM132A

CM133A

21. Remove the lock nuts (A) and (B) from the cap

screws of the MAG-side engine mounting bracket

and the front lower engine mounting bracket (do

not remove the cap screws at this time).