Snowmobile Arctic Cat (2008 year). Manual - part 25

2-37

2

MD0269

MD0268

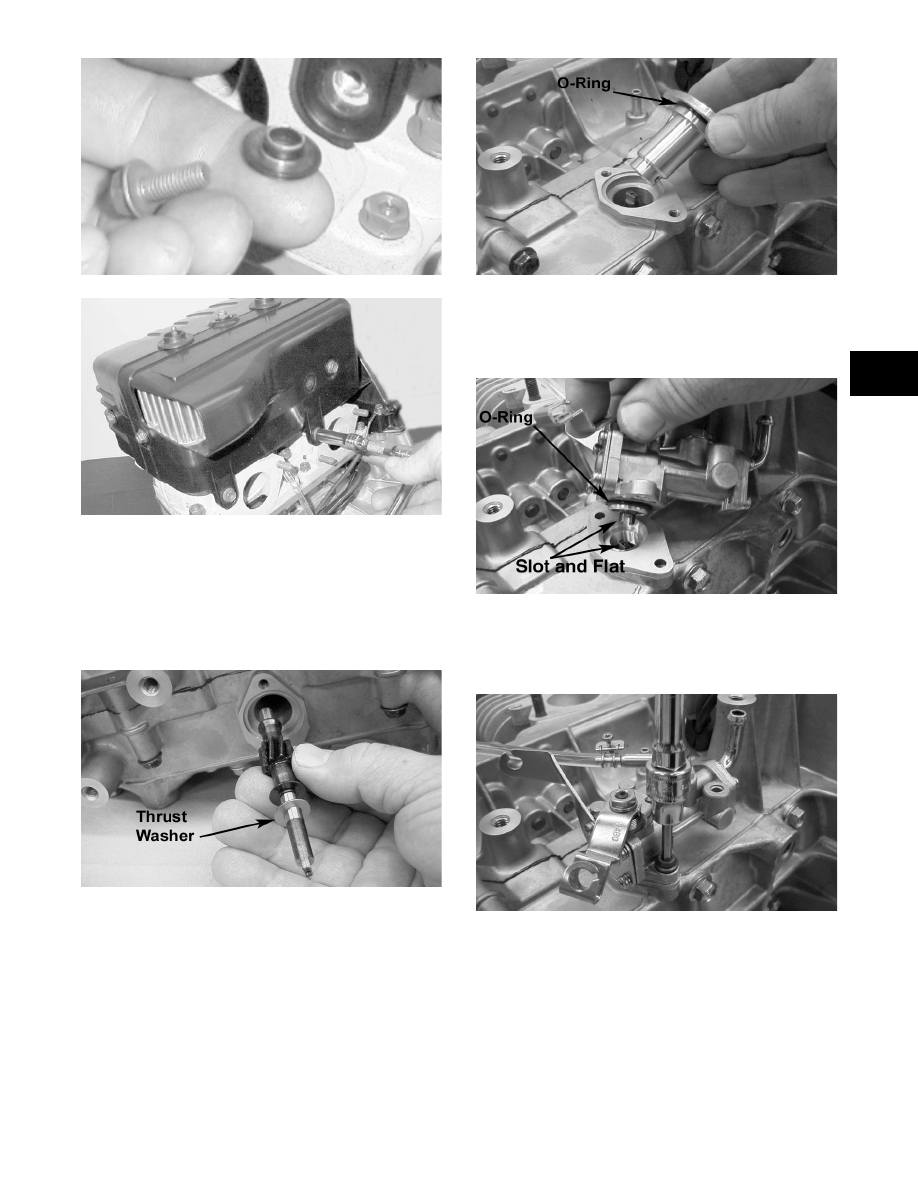

26. Lubricate the oil-injection pump driveshaft; then

while rotating the driveshaft, install it and the

thrust washer into the lower crankcase half.

NOTE: Make sure the thrust washer is installed

on the oil injection pump driveshaft when it is

installed.

MD0252

27. With a new O-ring in place, install the oil injection

pump driveshaft retainer.

MD0273

28. With a new O-ring in place, install the oil injection

pump aligning the slot on the oil pump with the

flat on the end of the oil injection pump driveshaft.

Tighten the Allen-head cap screws to 8 ft-lb.

MD0294

NOTE: For assembling purposes, always use

new O-rings lubricated with oil on the oil injection

pump and retainer.

MD0090

29. Install the first set of gaskets, heat deflector,

remaining gaskets, insulators, and flanges and

secure with nuts and washers. Tighten the nuts

(threads coated with red Loctite #271) to 15 ft-lb.

30. Install the exhaust manifold and gaskets with a

thin coat of High-Temp Sealant using lock wash-

ers and nuts. Tighten the nuts to 15 ft-lb.