Snowmobile Polaris Rush (2010 year). Manual - part 9

37

FEATURES

Instrument Cluster

Rider Information Center

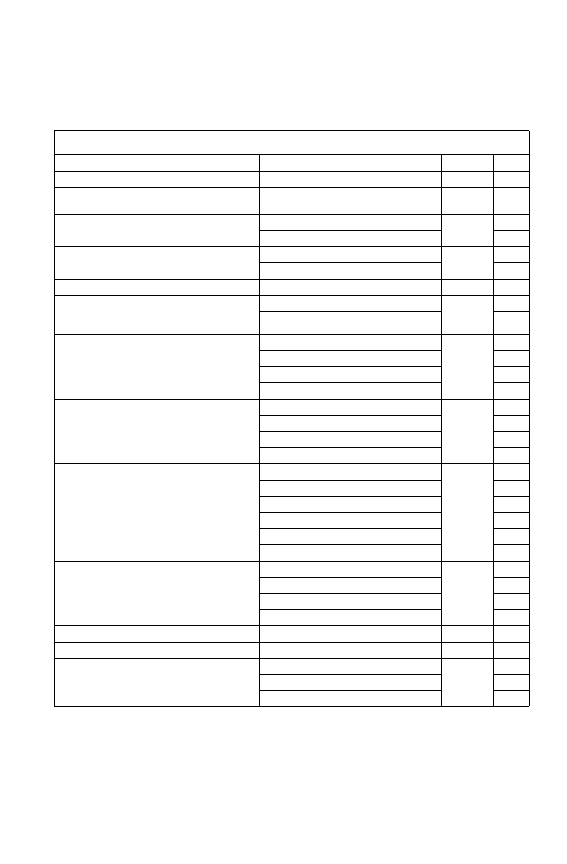

Diagnostic Display Code Definitions

Diagnostic Codes

Component

Condition

SPN

FMI

Ignition Coil Primary Driver 1 (MAG)

Driver Circuit Open/Grounded

1268

5

Fuel Pump Driver Circuit

Driver Circuit Open/Grounded

1347

5

Chassis Relay

Driver Circuit Open/Grounded

520208

5

Driver Circuit Short to B+

3

Exhaust Valve Solenoid

Driver Circuit Grounded

520215

5

Driver Circuit Short to B+

3

ECU Memory

Checksum/CRC Error

628

13

Alternator Power Supply Potential

(DC-SDI DC Chassis Voltage) (Fuel

Pump Power)

Voltage Too High

167

3

Voltage Too Low

4

Sensor Supply Voltage 1 (DC-SDI

TPS/TMAP PWR)

Voltage Too High

3509

3

Voltage Too Low

4

Voltage Above Critical Level

0

Voltage Below Critical Level

1

Sensor Supply Voltage 2 (DC-SDI

Ground Speed Sensor PWR)

Voltage Too High

3510

3

Voltage Too Low

4

Voltage Above Critical Level

0

Voltage Below Critical Level

1

ECU Output Supply Voltage 2 (DC-

SDI Injection Supply PWR)

Voltage Too High

3598

3

Voltage Too Low

4

Voltage Above Critical Level

0

Voltage Above Warning Level

16

Voltage Below Critical Level

1

Voltage Below Warning Level

18

Throttle Release Signal

Voltage Too High

520194

3

Voltage Too Low

4

Signal Out Of Range

2

Throttle Stuck

7

Knock Level Cylinder 1 (MAG)

Knock Above Critical Level

1352

0

Knock Level Cylinder 2 (PTO)

Knock Above Critical Level

1353

0

Fuel Type Selected

Voltage Too High

524007

3

Voltage Too Low

4

Signal Out Of Range

2