Snowmobile Polaris (2006 year). Manual - part 39

7.10

CLUTCHING

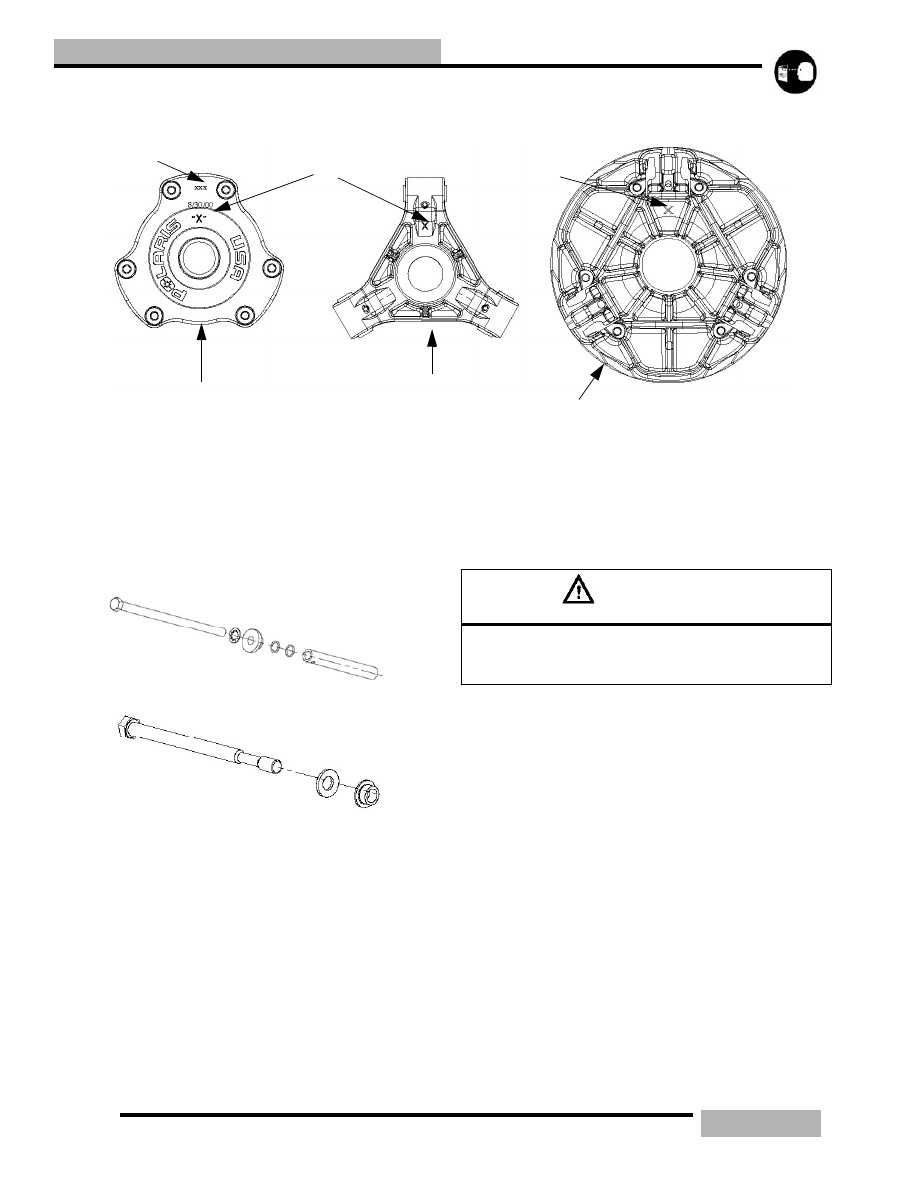

DRIVE CLUTCH IDENTIFICATION

Every clutch will have the last three digits of the clutch part

number etched on to the cover (A). The “X" (B) marking is an

index mark where the clutch cover (C), clutch spider (D) and

the stationary sheave (E) should line up when the clutch is

assembled.

DRIVE CLUTCH REMOVAL

NOTE: All clutch tools can be found at the

beginning of this chapter.

6.

Remove the belt See “DRIVE BELT” on page 7.4.

7.

Place the clutch holding tool (PN 9314177-A) on the drive

clutch.

8.

Remove the drive clutch retaining bolt. Note the

placement and number of washers that are on retaining

bolt.

9.

Place the correct clutch puller for the engine that you are

working on into the retaining bolt hole.

10. Tighten the puller into the clutch. If the clutch does not

come off, strike the clutch puller head with a hammer. If

the clutch does not “pop” off, continue to tighten the

clutch puller, and repeat this step.

A

B

C

D

B

E

Domestic

Fuji

CAUTION

Do not use a impact wrench to remove or install the

clutch bolt or clutch puller. Damage to the clutch and/or

crankshaft can occur.