Kincaid 8xp. Manual - part 12

- 51 -

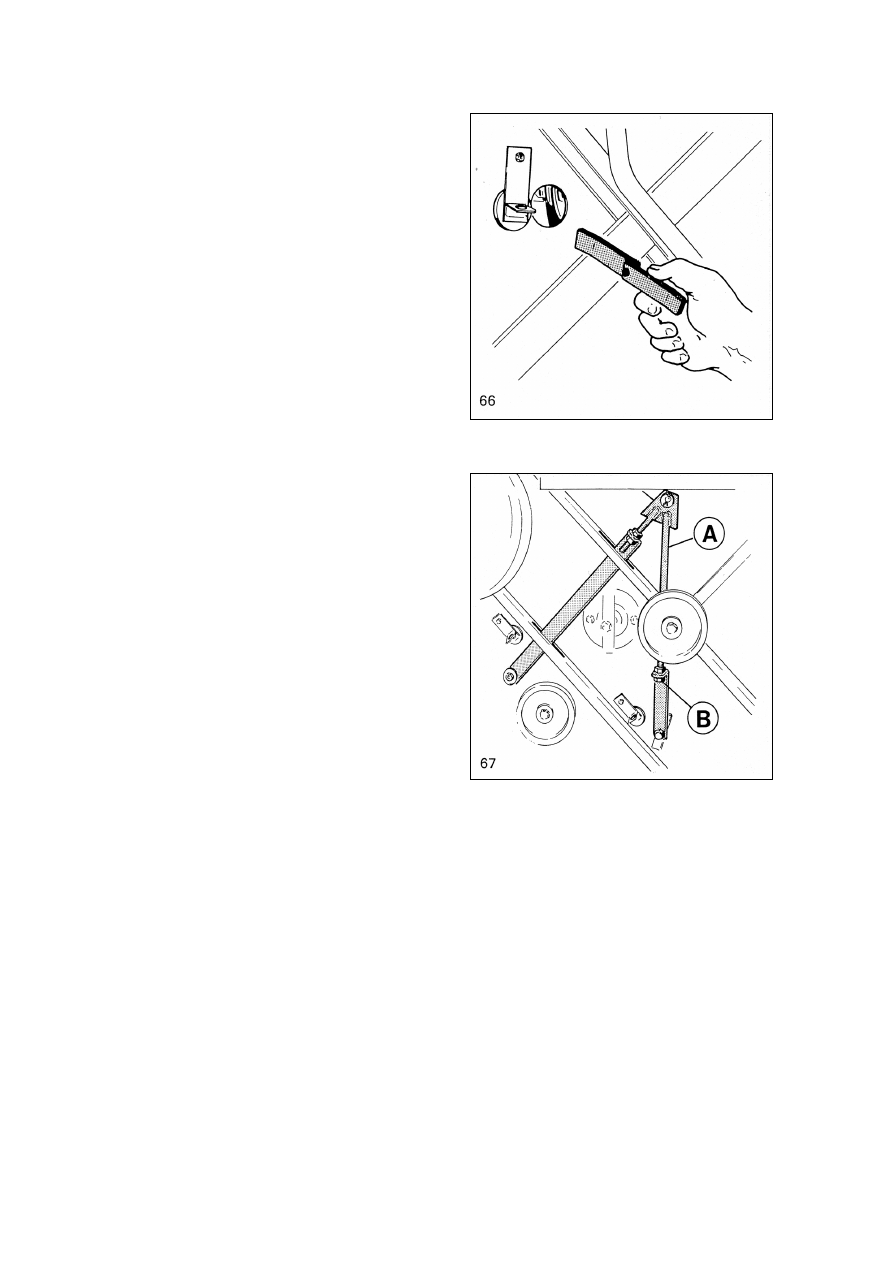

Cylinder/Concave Clearance

Periodically, preferably at the beginning of

each harvesting season, check the position

of the concave in relation to the threshing

cylinder, in other words the cylinder /

concave clearance. Use tool No. R152308

for checking, Fig 66.

Follow the instructions:

Set the concave adjustment lever to position

12 and check the clearance, which should

be 12 mm at the front (between the first

concave rasp bar and a cylinder rasp bar)

and 6 mm at the rear (between the last

concave rasp bar and a cylinder rasp bar).

If this is not in order, adjust the clearance

by nuts B at the lower end of the concave

adjusting arm A, Fig. 67. The check

measuring should be done in every concave

edge.