Kincaid 8xp. Manual - part 11

- 47 -

Check the Knife Fore/Aft

and Up/Down Positions.

Adjust the height by moving the drive lever

in its bearings. The fore/aft direction is

adjusted using screw joint A, fig. 55. The

up/down position is correct when the bottom

surface of the first knife section brushes the

cutting surface of the knife finger.

The fore/aft position is correct when the

knife tang and the joint fixing piece can

move freely for the whole length of the

stroke without brushing the edges of the

groove or the heads of the locking screws

on the knife finger.

Make sure the knife moves lightly when

turning the table auger drive pulley by hand

with the table disengaged.

Replacing and Aligning of

a Knife Section

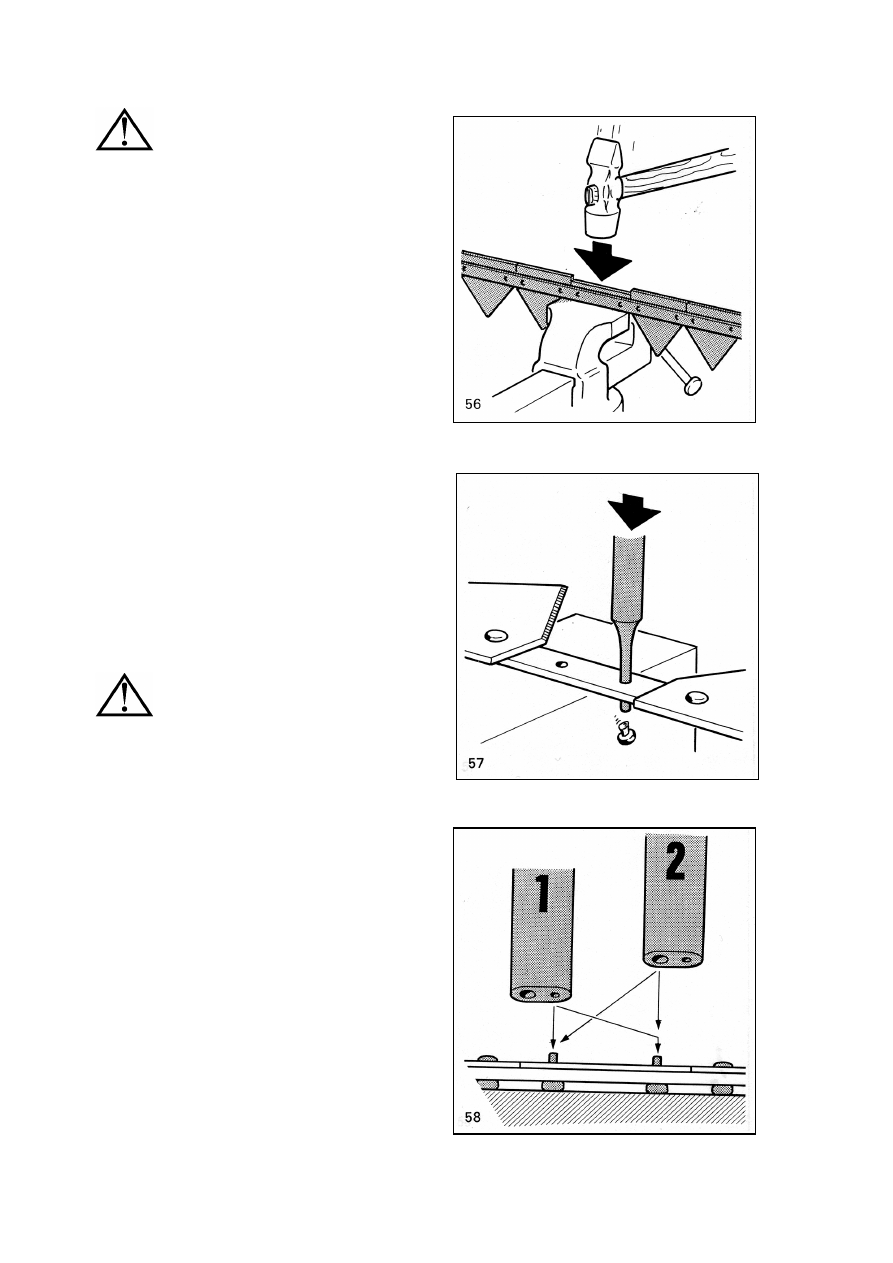

Remove the knife section by knocking out

the rivets according to Figs. 56 and 57. Rivet

up a new knife section. Use a riveting core

to tighten the section to knife tang 1 and

shape rivet head 2, fig. 58. Tool R 127831.